Electromagnetic shielding film, circuit board and preparation method of electromagnetic shielding film

An electromagnetic shielding film and circuit board technology, applied in the field of electronics, can solve the problems such as the inability of the shielding layer to conduct grounding, the easy expansion of the adhesive film layer, and the impact on the reliability of the grounding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

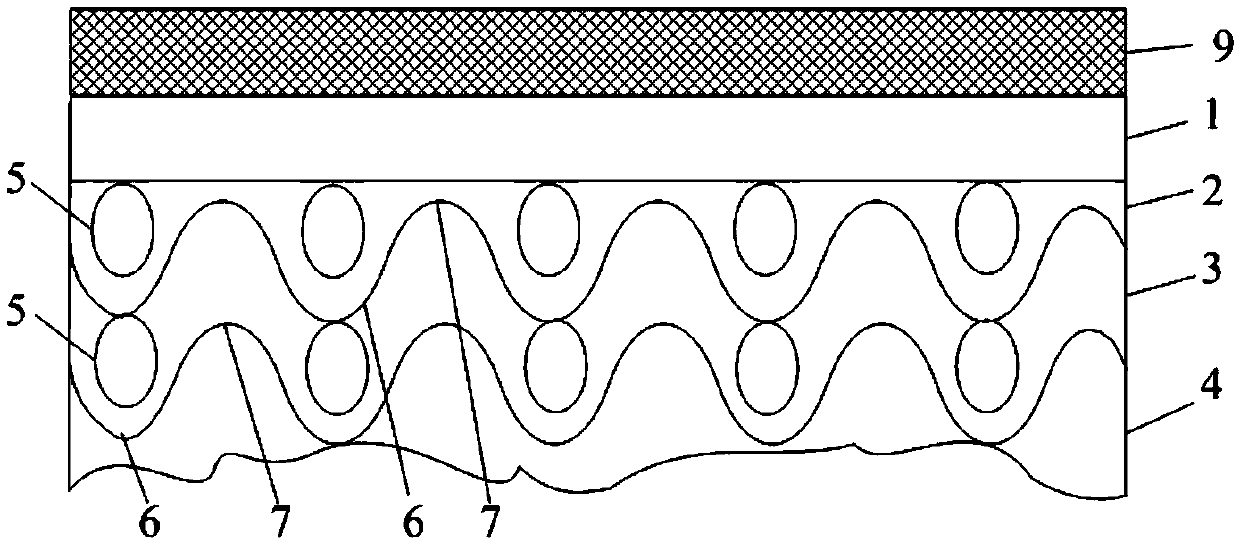

[0041] see figure 1, an electromagnetic shielding film according to a preferred embodiment of the present invention, comprising a first shielding layer 1, N second shielding layers 2, a third shielding layer 3, an adhesive film layer 4 and a plurality of convex particles 5; the first The shielding layer 1, N second shielding layers 2, the third shielding layer 3 and the adhesive film layer 4 are sequentially stacked; the side of the first shielding layer 1 close to the adhesive film layer 4 is flat On the surface, a plurality of convex particles 5 are distributed between the first shielding layer 1 and the second shielding layer 2 and between the second shielding layer 2 and the third shielding layer 3, the The surface of the third shielding layer 3 close to the adhesive film layer 4 is an uneven surface, and the adhesive film layer 4 is disposed on the third shielding layer 3 ; wherein, N is greater than or equal to 1. In this embodiment, N is 1, that is, there is one second...

Embodiment 2

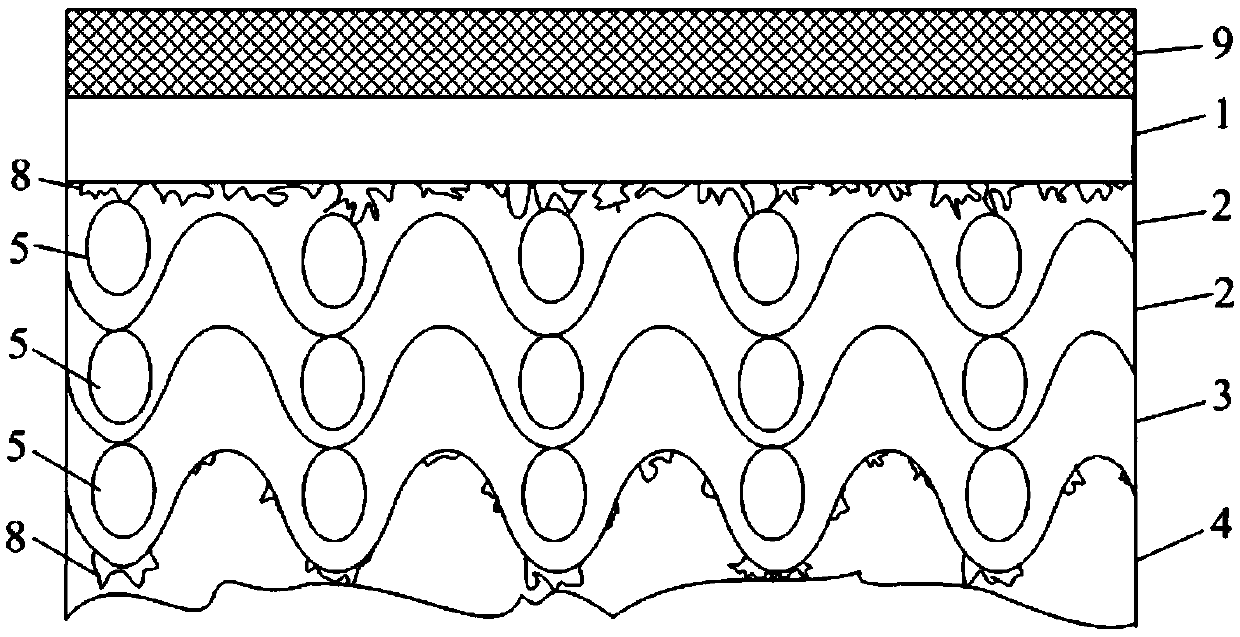

[0057] see figure 2 The difference between the electromagnetic shielding film of this embodiment and Embodiment 1 is that one or more of the second shielding layers 2 in this embodiment are attached with a plurality of said protrusions on the side close to the adhesive film layer 4. Shaped particles5. A plurality of convex particles 5 are attached to one or more of the second shielding layers 2 on the side close to the glue film layer 4, thereby facilitating increasing the proximity of the third shielding layer 3 to the glue. The undulation of one side of the film layer 4 further effectively improves the puncture strength of the third shielding layer 3 . Preferably, one or more of the plurality of convex particles 5 attached to the side of the second shielding layer 2 close to the adhesive film layer 4 are concentrated on the convex portion 6 of the second shielding layer 2 . In this embodiment, N is 2, that is, there are 2 second shielding layers 2 .

[0058] see figure ...

Embodiment 3

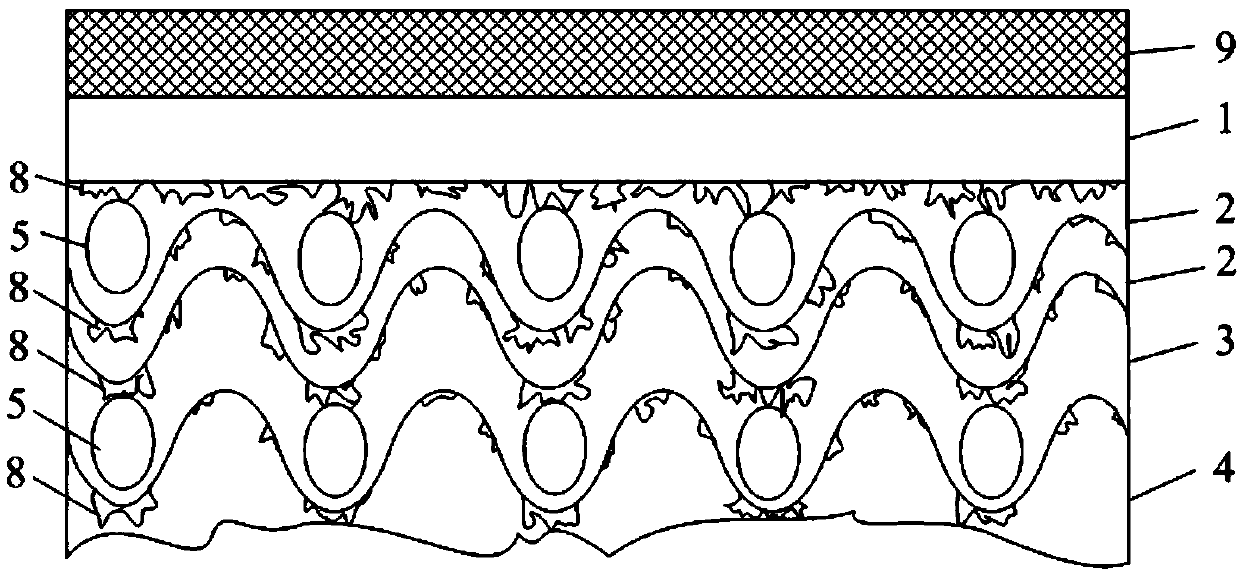

[0065] see image 3 The difference between the electromagnetic shielding film of this embodiment and the second embodiment is that one or more of the second shielding layers 2 in this embodiment are provided with conductive protrusions 8 on the side close to the adhesive film layer 4 . By providing conductive protrusions 8 on one or more of the second shielding layers 2 near the adhesive film layer 4, it is beneficial to increase the distance between the third shielding layer 3 and the adhesive film layer 4. The undulation of one side effectively improves the puncture strength of the third shielding layer 3 . Preferably, one or more conductive protrusions 8 on the side of the second shielding layer 2 close to the adhesive film layer 4 are collectively arranged on the protrusion 6 of the second shielding layer 2 .

[0066] In a specific implementation, the second shielding layer 2 may be formed first, and then the conductive protrusion 8 is formed on the second shielding layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com