Processing equipment of fish feeds for aquaculture use

A technology for aquaculture and processing equipment, applied in the direction of feed, application, food science, etc., can solve the problems of uneven mixing, low efficiency, and inability to form fishmeal, and achieve the effects of saving costs, being easy to eat, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

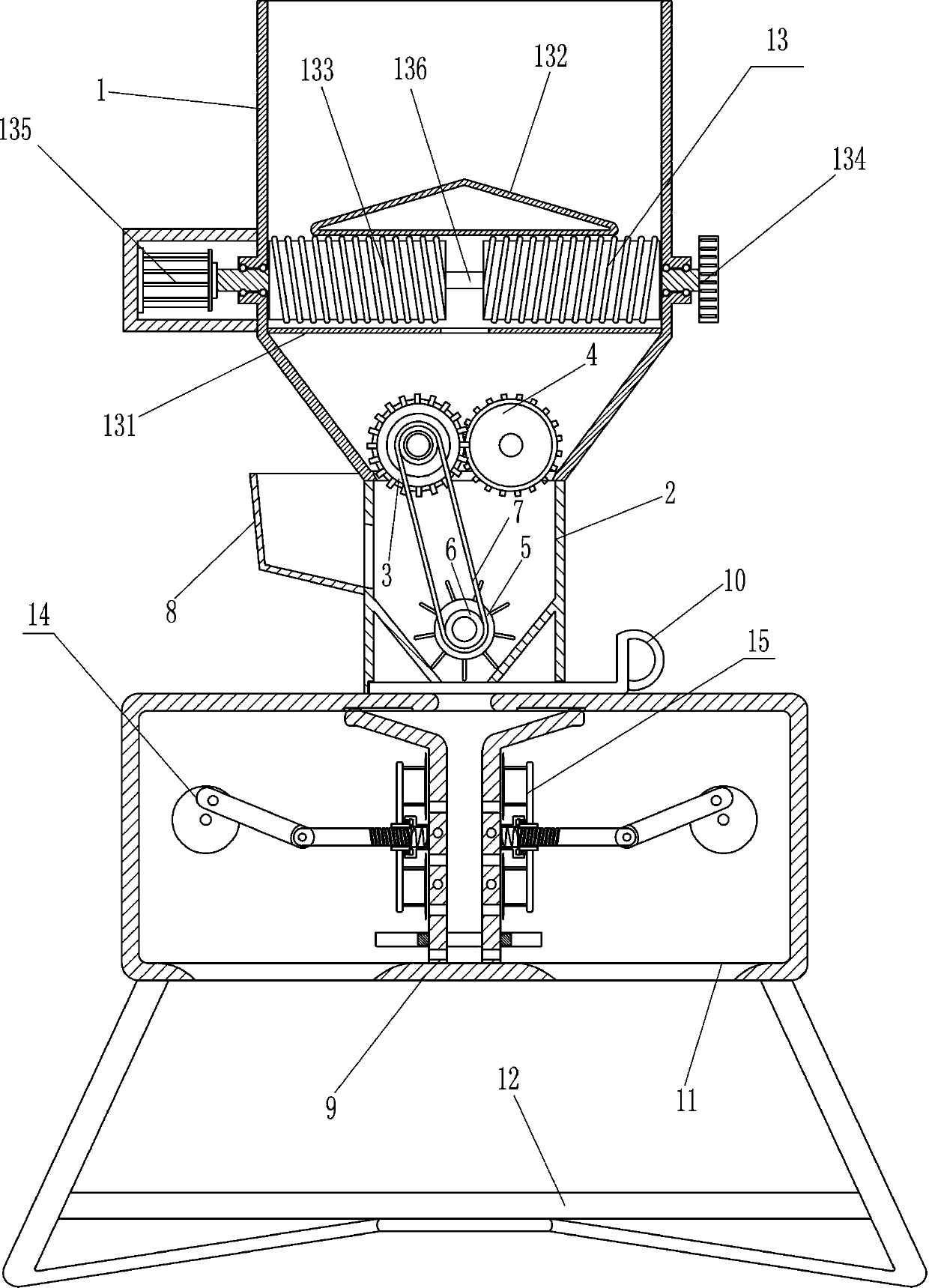

[0018] A fish feed processing equipment for aquaculture, such as figure 1 As shown, it includes a base 12, a rectangular frame 9, a hopper 1 and a barrel 2. The top of the base 12 is provided with a rectangular frame 9. The rectangular frame 9 is connected to the base 12 by means of bolts, and the top of the rectangular frame 9 is connected to the barrel 2. , the top of the barrel 2 is provided with a hopper 1, the barrel 2 and the hopper 1 are integrally formed, and the barrel 2 is respectively connected with the rectangular frame 9 and the hopper 1, and also includes an electric crushing roller 3, a driven crushing roller 4, a mixing Roller 5, pulley 6, flat belt 7, side hopper 8 and baffle plate 10, electric crushing roller 3 and driven crushing roller 4 are arranged in the lower part of the hopper 1, and the electric crushing roller 3 is located on the driven crushing roller 4 On the left side, the driven crushing roller 4 is rotatably connected to the hopper 1, and the mi...

Embodiment 2

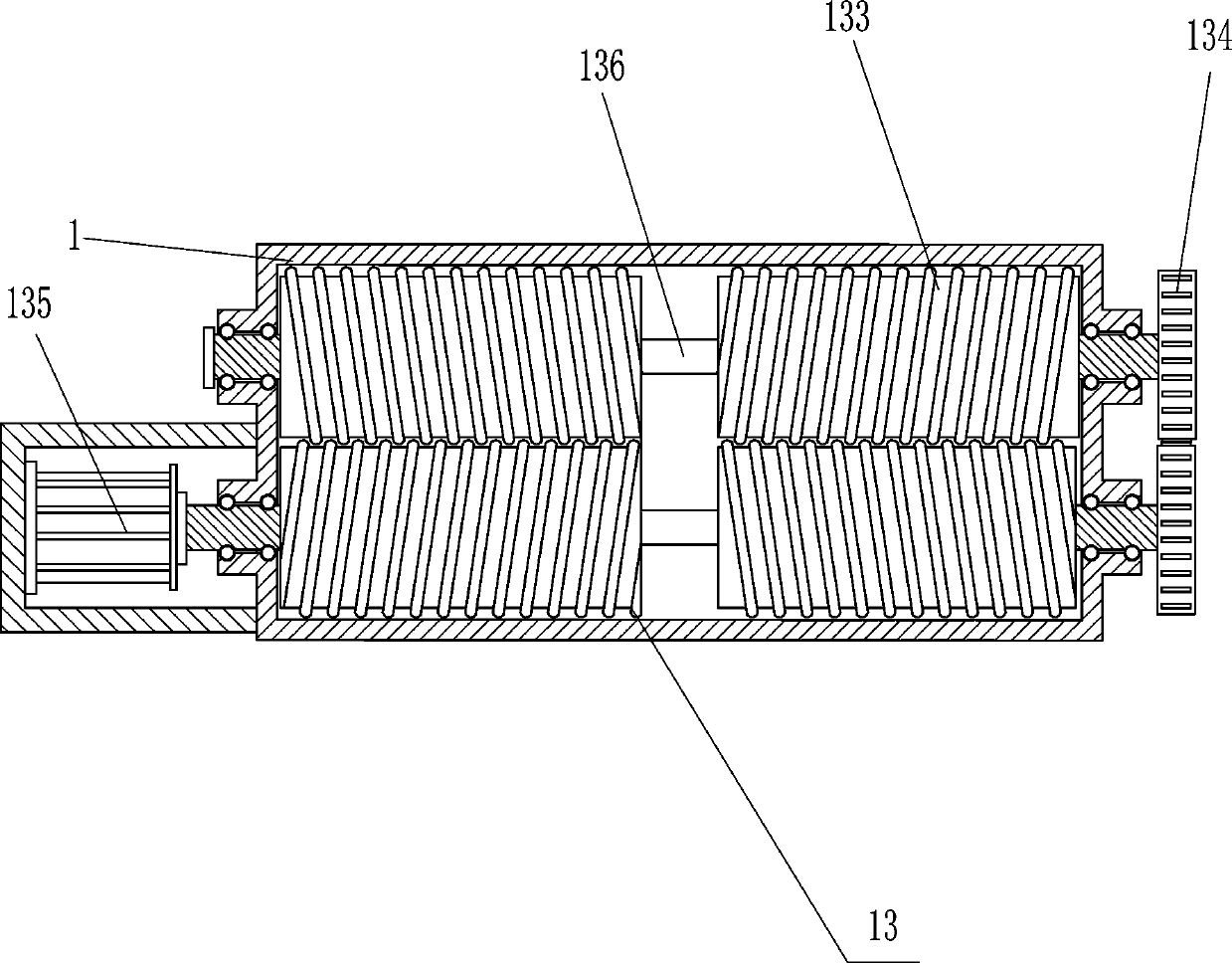

[0021] Such as Figure 1-2 As shown, it also includes a crushing device 13. The crushing device 13 includes a horizontal plate 131, a triangular deflector 132, a spiral crushing roller 133, a gear belt 134, a reduction motor 135 and a connecting shaft 136. The hopper 1 is provided with The horizontal plate 131 and the triangular deflector 132, the middle part of the horizontal plate 131 has a through hole, the horizontal plate 131 is located above the electric crushing roller 3, the triangular deflector 132 is located above the horizontal plate 131, the front and rear ends of the triangular deflector 132 They are respectively connected to the front and rear side walls in the hopper 1. Two spiral crushing rollers 133 are arranged on the left and right sides of the hopper 1. The two spiral crushing rollers 133 are symmetrically arranged front and rear, and the front and rear two spiral crushing rollers 133 are mutually Cooperating, the spiral crushing roller 133 is located betwe...

Embodiment 3

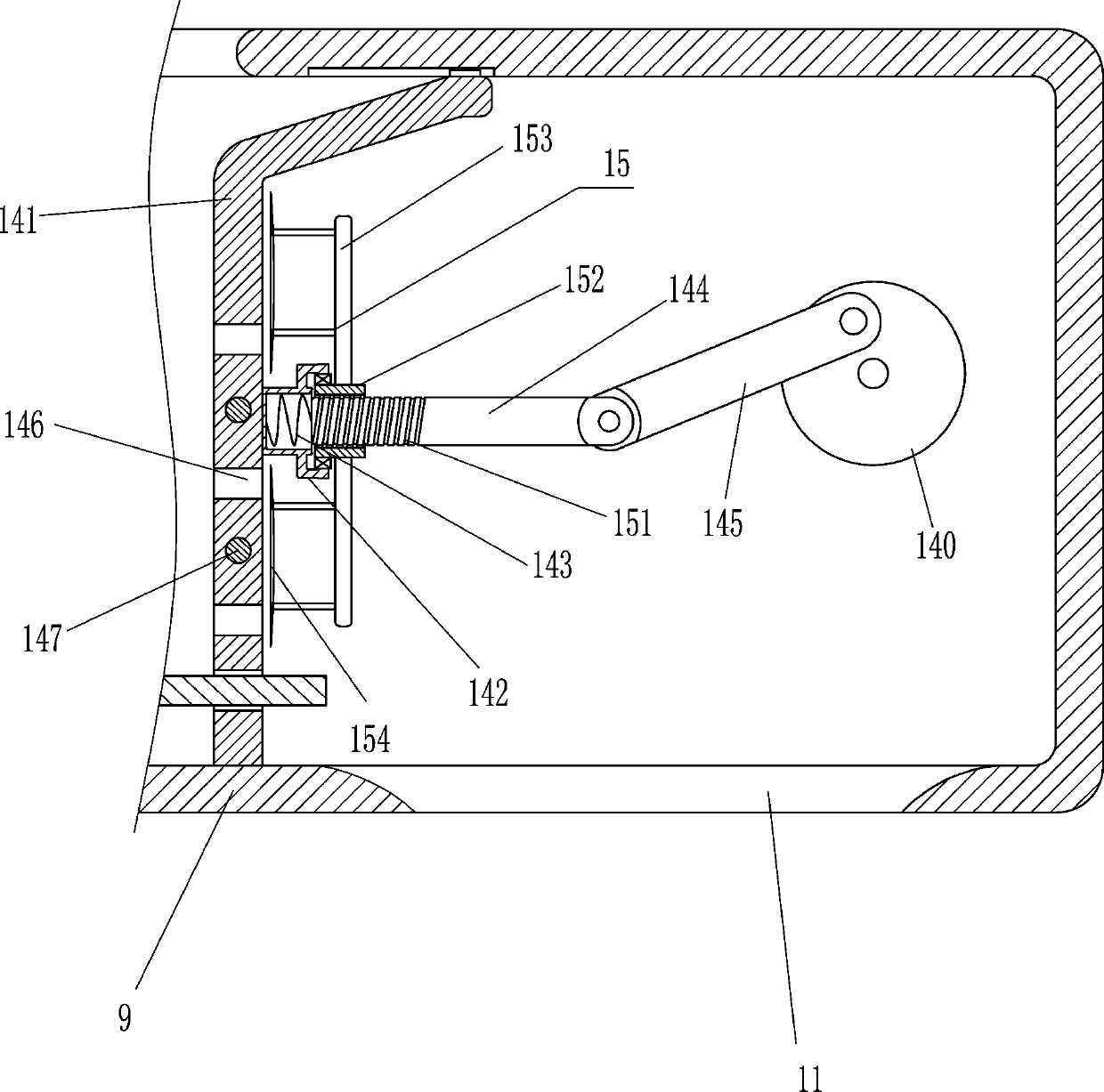

[0024] Such as Figure 3-4 As shown, extruding device 14 is also included, and extruding device 14 includes electric disc 140, extruding plate 141, sleeve 142, spring 143, push rod 144, connecting rod 145 and heating rod 147, and inside rectangular frame 9 The left and right sides are symmetrically equipped with electric discs 140, the top, left and right sides of the rectangular frame 9 are slidingly provided with extruding plates 141, and the outer sides of the two extruding plates 141 are provided with sleeves 142, and the sleeves 142 are connected by bolts The way is connected with the extrusion plate 141, the sleeve 142 is provided with a push rod 144, the spring 143 is connected between the push rod 144 and the extrusion plate 141, the spring 143 is located in the sleeve 142, the push rod 144 and the electric disc 140 is rotatably connected with a connecting rod 145, and three forming holes 146 are evenly spaced on the extruding plate 141, and a heating rod 147 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com