A green, low-cost flue gas mercury removal method

A low-cost, flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problem of high preparation cost, achieve the effect of simple preparation process, high-efficiency catalytic oxidation, and solve environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Red mud (Bayer process red mud, Al 2 o 3 The mass content is 10wt%, Fe 2 o 3 The mass content is 25wt%) into 4 times the volume of water, continue to stir and filter, collect the filtrate, recover the alkali in the red mud, and record the filtrate as s1; add 0.5mol / L hydrochloric acid to the obtained red mud, add acid measuring solution Solid ratio L / S=8mL / g, stir for 2 hours to dissolve part of the metal Al and Fe in the red mud, and the obtained suspension is recorded as s2;

[0027] (2) Slowly add the filtrate s1 to the suspension s2 under continuous stirring, the added amount of liquid-solid ratio L / S=4mL / g, continue to add water 20 times the volume of the filtrate s1, stir for 2 hours, and stand at room temperature for 8 hours, Make the dissolved part of Al and Fe form hydroxyl compounds, and the resulting suspension is denoted as s3;

[0028] (3) Add the dry montmorillonite to the suspension s3 in an amount equal to 1 times the mass of the solid in the sus...

Embodiment 2

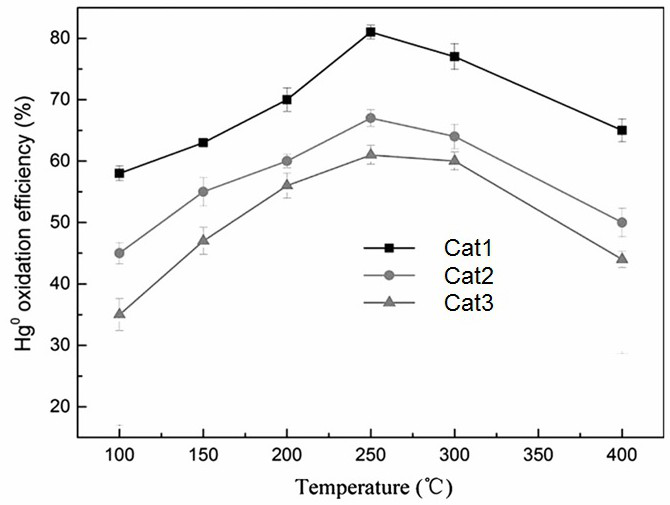

[0031] The prepared mercury removal catalyst Cat1 (0.3g) was packed in a fixed bed reactor, and the simulated flue gas was passed through. The composition of the simulated flue gas was 4% O 2 , 10% CO 2 , 400 ppm SO 2 , 8%H 2O, 10 ppm HCl, 200 ppm NO, and N 2 Balance gas; using CO 2 Hg as carrier 0 (50μg / m 3 ) into the reactor with a flow rate of 1L / min and a space velocity of 10000h -1 . The mercury oxidation rate was calculated by measuring the mercury content at the outlet of the reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com