Method for lubricating strip steel

A technology for strip steel and ester synthesis, which is applied in workpiece lubricating devices, workpiece surface treatment equipment, metal rolling, etc., can solve problems such as insufficient rolling lubricity, and achieve the effect of improving rolling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

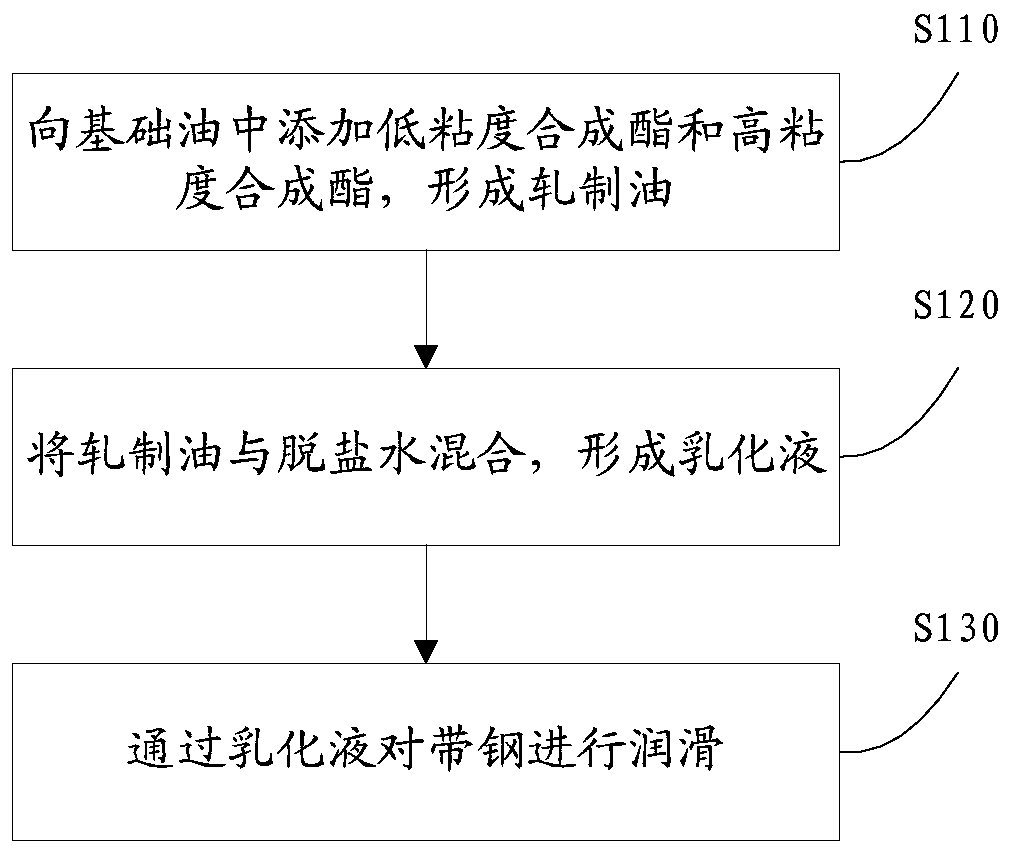

[0026] The embodiment of the present invention solves the technical problem of insufficient rolling lubricity in the prior art by providing a strip lubrication method, and achieves the technical effect of improving the rolling stability of acid continuous rolling non-oriented electrical steel.

[0027] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

[0028] First add low-viscosity synthetic ester and high-viscosity synthetic ester to the base oil to form rolling oil; among them, the kinematic viscosity η of low-viscosity synthetic ester 40 The range is [4,15]mm 2 / s, kinematic viscosity η of high-viscosity synthetic ester 100 The range is [1000-1800]mm 2 / s; Mix rolling oil with desalted water to form an emulsion; lubricate the strip through the emulsion. By limiting the kinematic viscosity of low-viscosity synthetic esters and high-viscosity synthetic esters, it is possible to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com