A polishing and grinding machine that realizes variable diameter through the cooperation of screw and bevel gear

A technology of polishing and bevel gears, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve the problems of large dead angle of grinding, low polishing efficiency of workpiece, unadjustable active radius, etc., and achieve low cost , Guarantee the polishing effect, and solve the effect of large dead angle of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

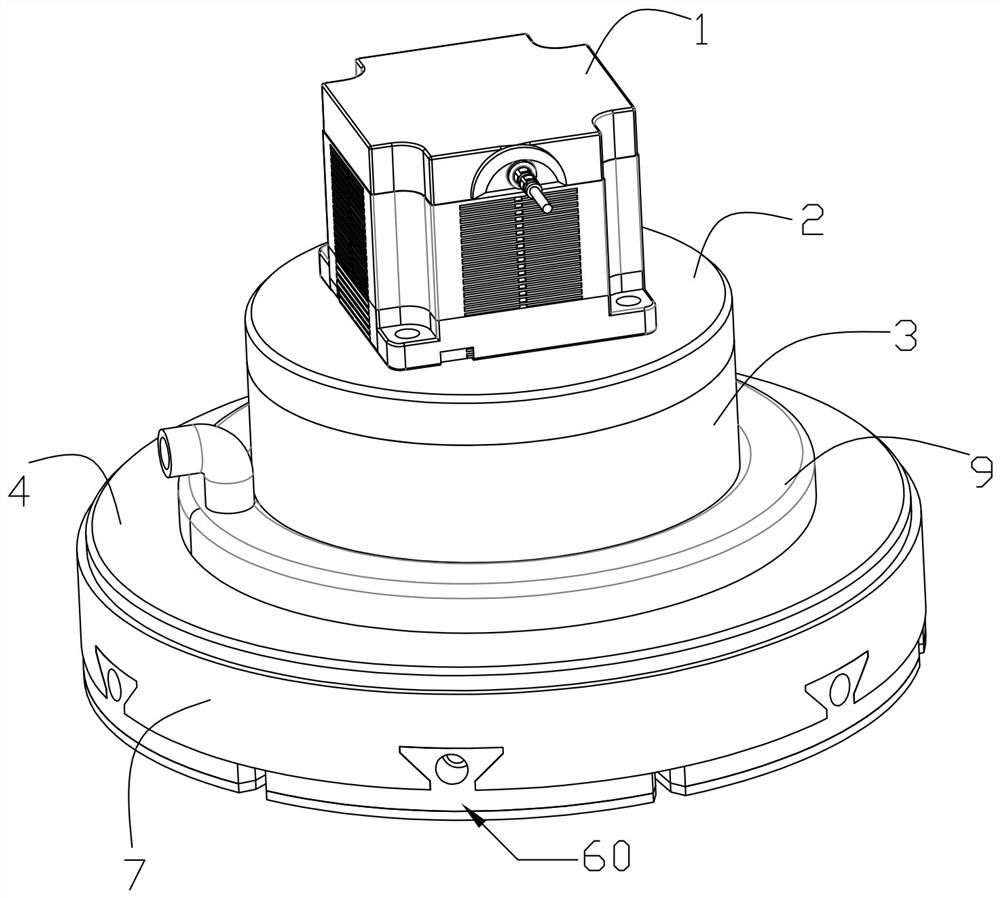

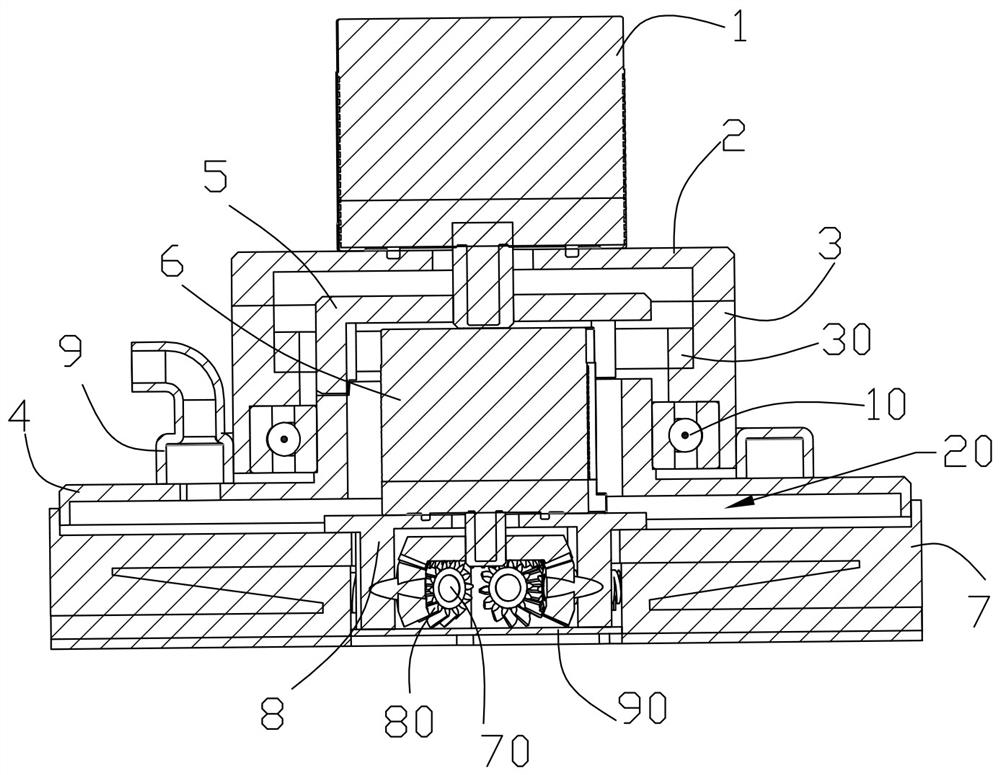

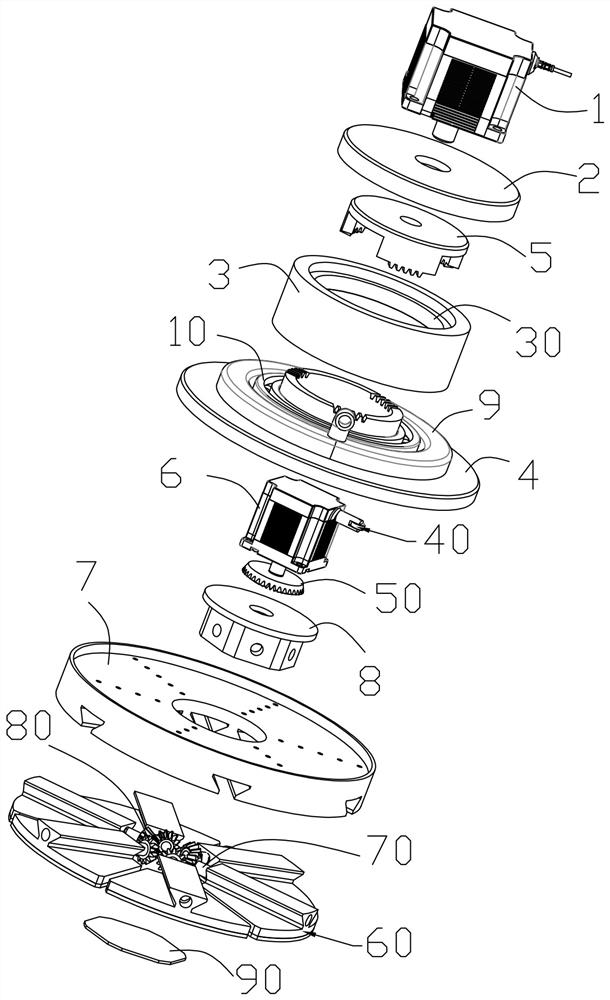

[0022] like Figure 1 to Figure 11 As shown in the figure, the polishing and grinding machine described in this embodiment, which realizes diameter reduction through the cooperation of a screw rod and a bevel gear, includes a first motor 1, a top cover 2, a cylindrical fixing sleeve 3, a dust collecting cover seat 4, an end surface Gear 5, second motor 6, grinding groove plate 7, screw fixing frame 8 and air ring 9, the first motor 1 is fixed on the top surface of the top cover 2, and its output end passes down through the top cover 2 and is connected to the end surface The middle part of the gear 5 is fixedly connected, the top cover 2 is covered on the top of the fixed sleeve 3, the dust collecting cover base 4 includes a dust collecting cover body 41 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com