Feeding mechanism of container

A container and feeding technology, applied in the direction of lifting device, etc., can solve problems such as reducing stability, increasing floor space, increasing shaking amplitude, etc., to reduce the number of times, improve position accuracy, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

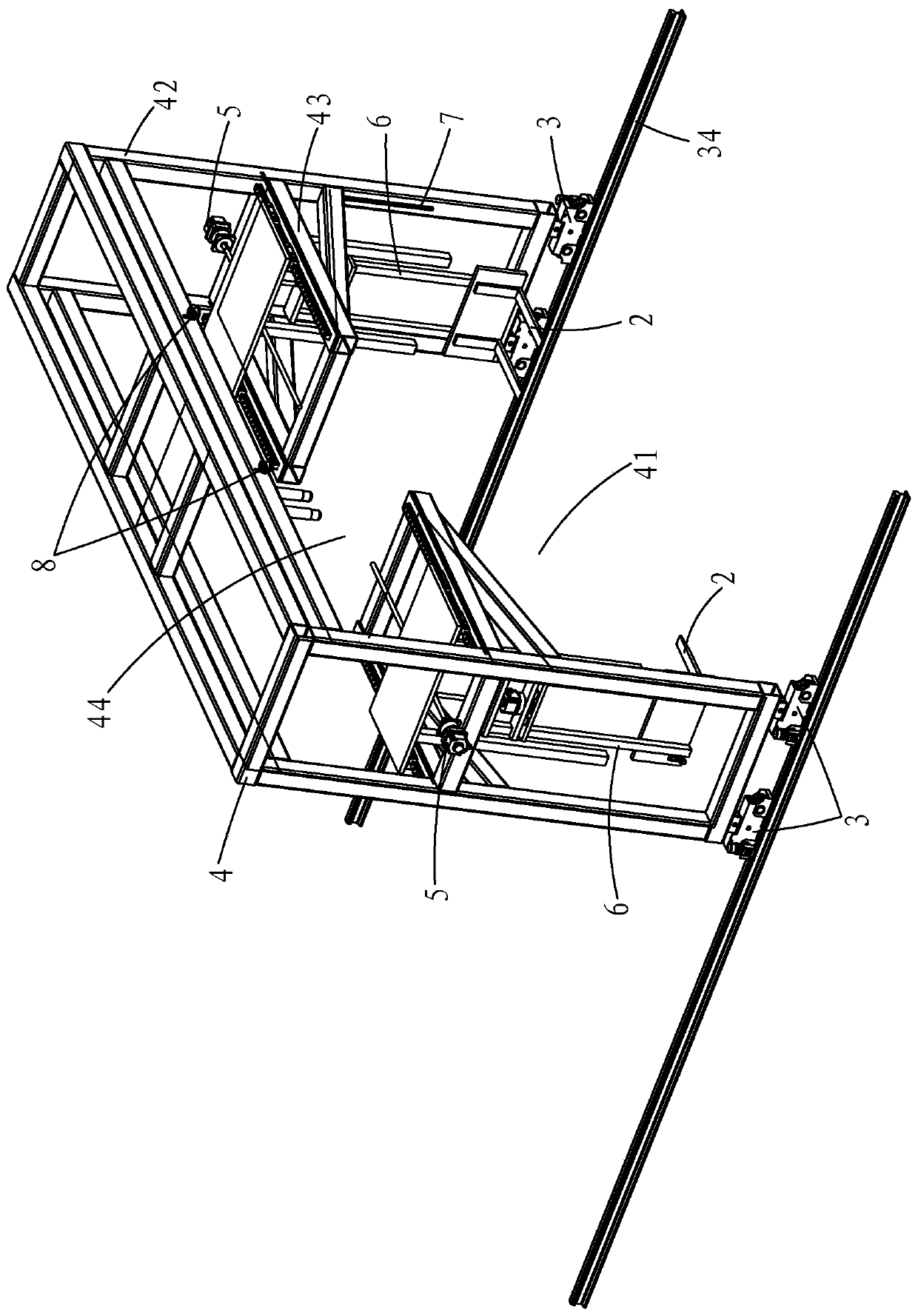

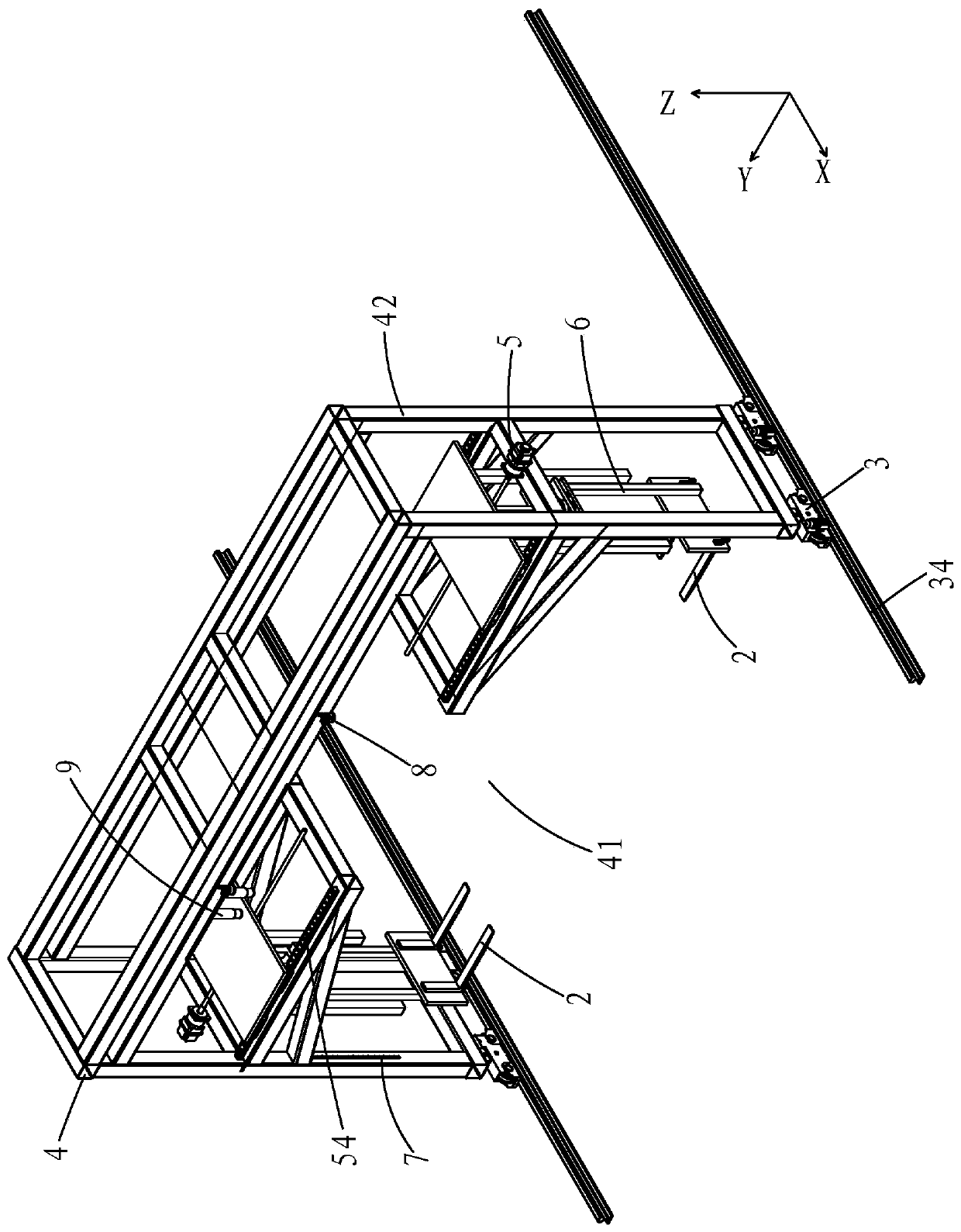

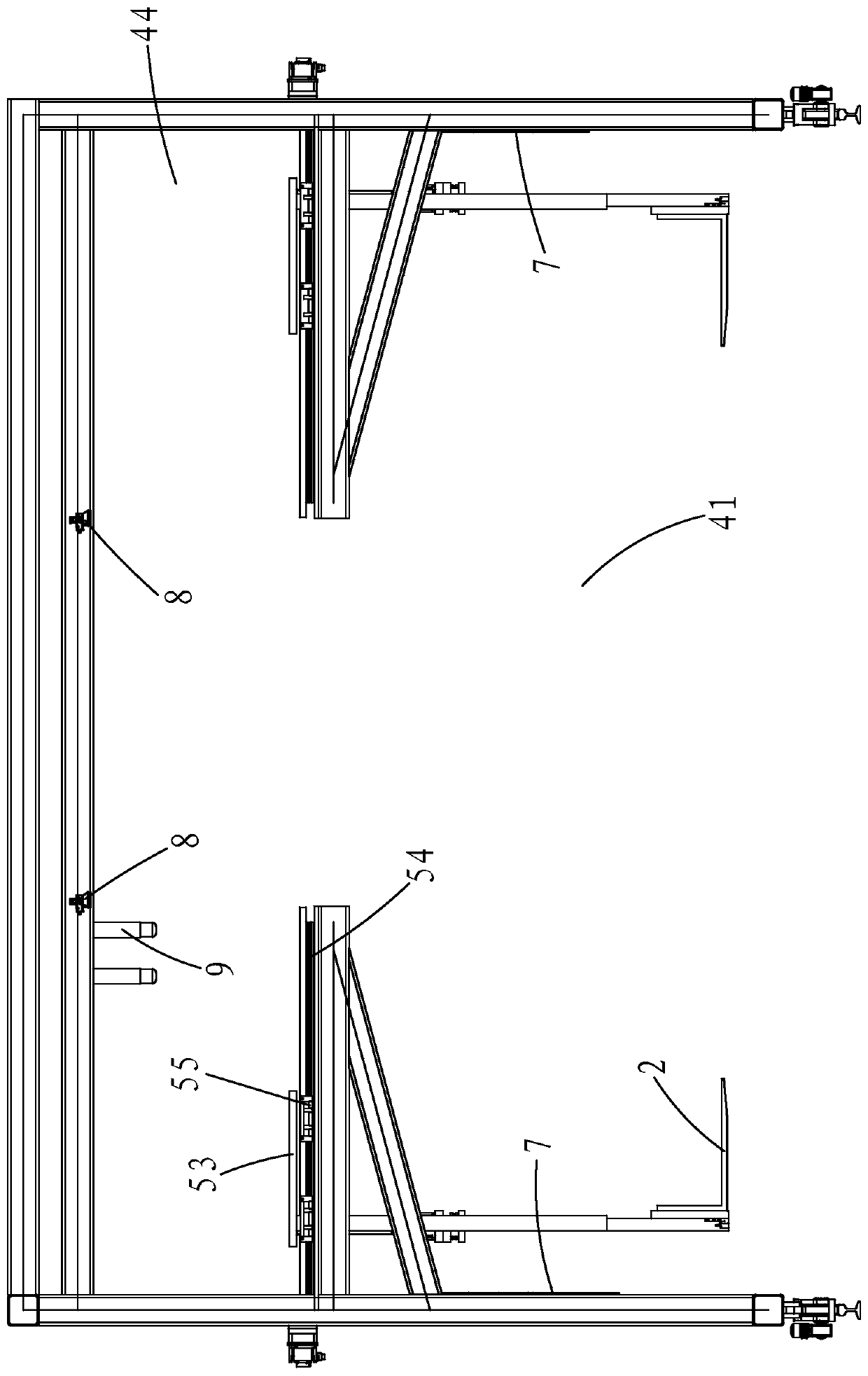

[0069] A cargo loading and unloading system 100 for a flying wing container or a quick-opening side curtain box, including the feeding mechanism, the conveying device 1, the first detection device 7, the second detection device 8, the alarm device 9 and the controller described in the present invention ;

[0070] The feeding mechanism includes an X-axis moving module 3 , a support frame 4 , a Y-axis moving module 5 , a Z-axis moving module 6 and a pallet fork 7 .

[0071] Wherein, the conveying device 1 is arranged in a straight line along the X-axis; the conveying device 1 is used for conveying goods 200 . When loading, the goods 200 can be placed on the conveying device 1 with a forklift, because the conveying device 1 plays the role of transmission, and the position accuracy requirement is lower than that of using a forklift to fork into the container, which is more convenient to operate and reduces the cost of operation. difficulty; and for storage systems with a high deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com