Concrete for steel pipe arches and steel pipe concrete arch bridge

A technology of concrete and steel pipes, which is applied in the field of concrete, can solve problems such as poor compatibility between steel pipe arch ribs and concrete, concrete compactness, and expansion performance that cannot meet the application requirements of concrete for steel pipe arches, etc., so as to improve service life, ensure close integration, Effect of good pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

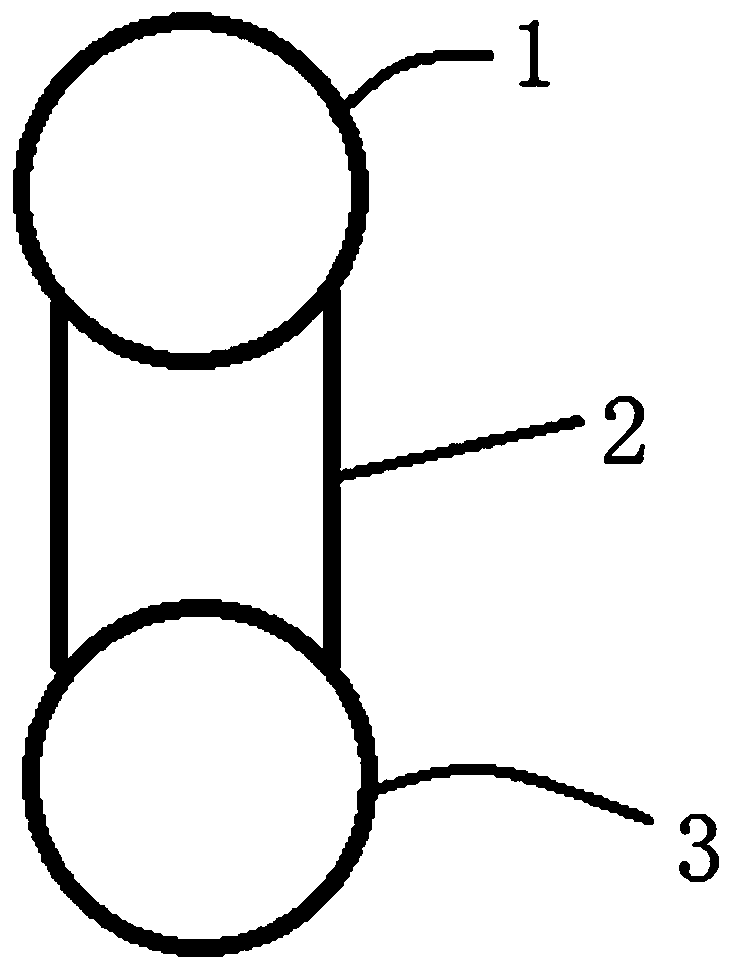

Image

Examples

Embodiment 1

[0035] The steel pipe arch concrete of the present embodiment is made of the following raw materials: cement 392kg / m 3 , fly ash 63kg / m 3 , mineral powder 32kg / m 3 , expansion agent 53kg / m 3 , sand 758kg / m 3 , gravel 965kg / m 3 , water reducer 7kg / m 3 , water 151kg / m 3 .

[0036] Dry mix cement, fly ash, mineral powder, expansion agent, sand, and gravel in a mixer to obtain mixed powder; mix water reducer and water to obtain a mixed solution; mix the mixed solution and mixed powder in a mixer Uniform, that is.

Embodiment 2

[0038] The steel pipe arch concrete of the present embodiment is made of the following raw materials: cement 438kg / m 3 , fly ash 71kg / m 3 , mineral powder 36kg / m3 , expansion agent 59kg / m 3 , sand 713kg / m 3 , gravel 944kg / m 3 , water reducer 7.9kg / m 3 , water 151kg / m 3 .

Embodiment 3

[0040] The steel pipe arch concrete of the present embodiment is made of the following raw materials: cement 353kg / m 3 , fly ash 57kg / m 3 , mineral powder 29kg / m 3 , expansion agent 48kg / m 3 , sand 799kg / m 3 , gravel 977kg / m 3 , water reducer 6.3kg / m 3 , water 151kg / m 3 .

[0041] Concrete for Steel Tube Arch The preparation method of the concrete in Example 2 and Example 3 is the same as that in Example 1.

[0042] Two, the concrete embodiment of steel pipe concrete arch bridge of the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com