Novel distributed permeable pavement and paving method

A permeable pavement, distributed technology, applied in the direction of roads, roads, pavement details, etc., to achieve the effect of reducing road surface water and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

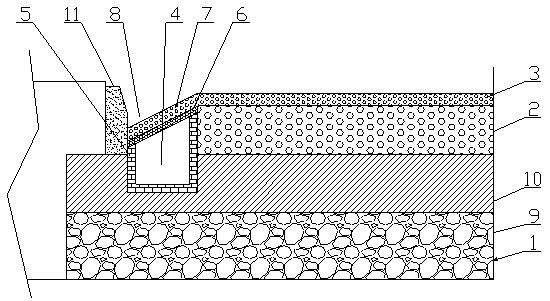

[0019] see figure 1 , the embodiment of the present invention provides a new type of distributed permeable pavement, including the pavement and the drainage ditches 4 on both sides thereof. and it is connected to the municipal drainage system through pipes or ditches. The aforementioned structure is basically consistent with the structure of the existing municipal pavement, except that the surface course 3 in this embodiment is a steel slag asphalt mixture, which is a new type of pavement surface material and has been widely used. Good water permeability and long service life and other advantages. The drainage ditch 4 penetrates the permeable layer 2 and goes deep into the base layer 1, and it is built with permeable bricks 5. The permeable bricks 5 on the inside can collect the seepage of the permeable layer 2, and the permeable bricks 5 on the outside and bottom surface can realize part of the drainage ditch. The drainage in 4 seeps outwards to meet the requirements of the...

Embodiment 2

[0027] This embodiment provides the paving method of the novel distributed permeable pavement disclosed in Embodiment 1. The method includes: paving the base layer 1 and digging trenches on both sides of the base layer 1, and using permeable bricks 5 in the ditch (three sides) A drainage ditch 4 with a certain height (it is best to ensure that the end of the orifice plate 6 close to the road surface is flush with the permeable layer 2), and the permeable layer 2 is paved on the base layer 1 and between the drainage ditch 4 on both sides, and the drainage ditch 4 The upper cover is provided with a perforated plate 6, the steel slag asphalt mixture is paved on the perforated plate 6 and the permeable layer 2, and the side ditch permeable layer 7 and the surface layer 3 are formed at the same time. The edge forms a gutter 8.

[0028] Among them, see figure 1 In the present invention, paving the base 1 and digging trenches on both sides of the base 1 include: paving the graded gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com