A spiral cartridge type composite spiral anchor and a spiral cartridge

A composite spiral and spiral card technology, which is applied in the direction of sheet pile walls, building types, buildings, etc., can solve the problems of low appendages or vegetation damage, high cost, and long construction period, so as to make full use of strength and improve bearing capacity , the effect of reducing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

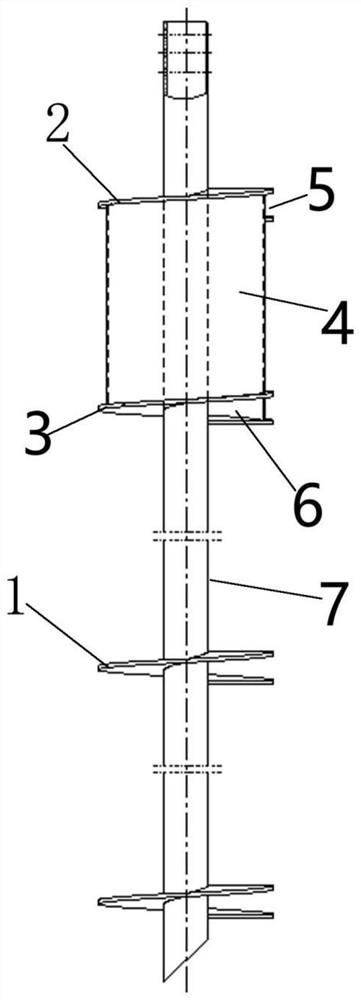

[0024] Such as Figure 1-Figure 3 As shown, a spiral cartridge type composite spiral anchor includes an anchor rod, a spiral anchor disc 1 and a spiral cartridge. The anchor rod comprises a guide anchor rod 7, and the spiral anchor disc 1 is arranged on the guide anchor rod 7, and the diameter of the guide anchor rod 7 is 219mm.

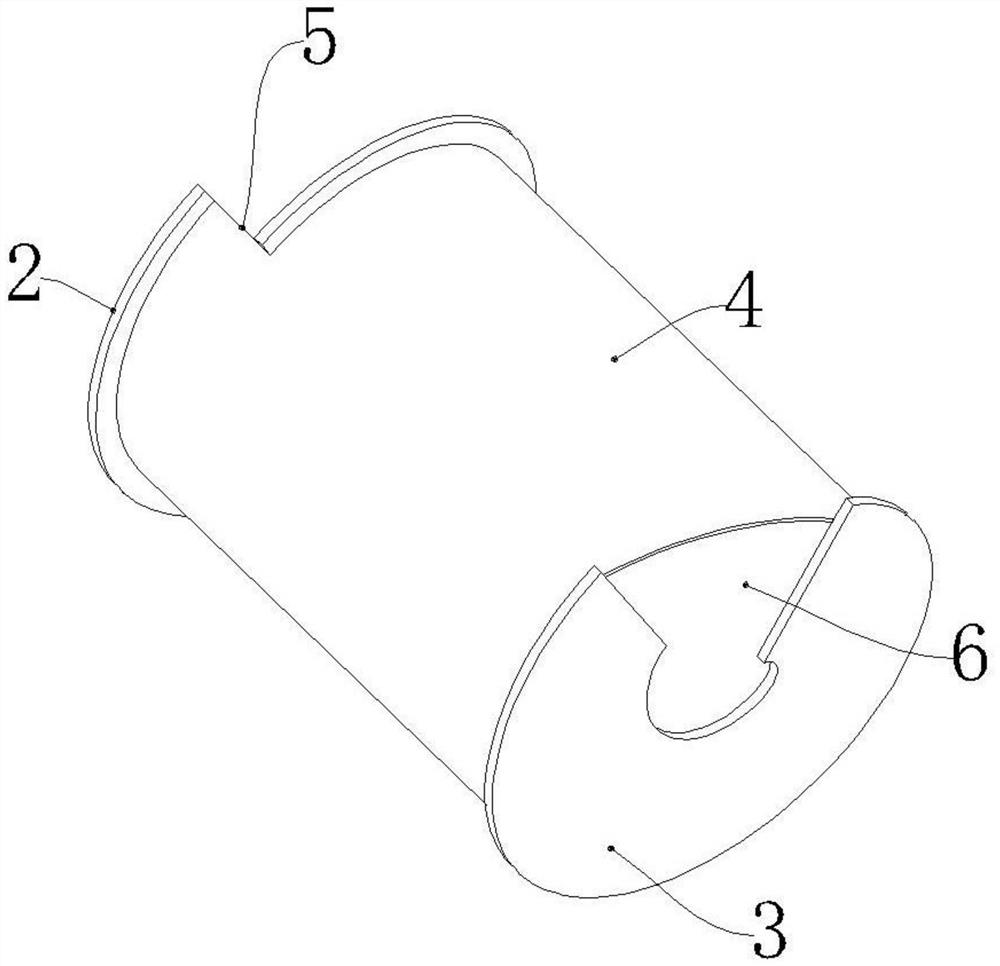

[0025] The spiral cartridge includes an upper spiral anchor plate 2 , a lower spiral anchor plate 3 and a cylinder body 4 . The upper spiral anchor disk 2 of the card cartridge and the lower spiral anchor disk 3 of the cartridge are fixed on the guide anchor rod 7 at intervals, the upper spiral anchor disk 2 of the card cartridge and the lower spiral anchor disk 3 of the card cartridge are coaxial with the guide anchor rod 7, The spiral anchor plate 2 on the cylinder is 1000mm away from the top end of the guide anchor rod 7 . The diameters of the spiral anchor disk 1, the upper spiral anchor disk 2 of the card cartridge and the lower spiral anchor ...

Embodiment 2

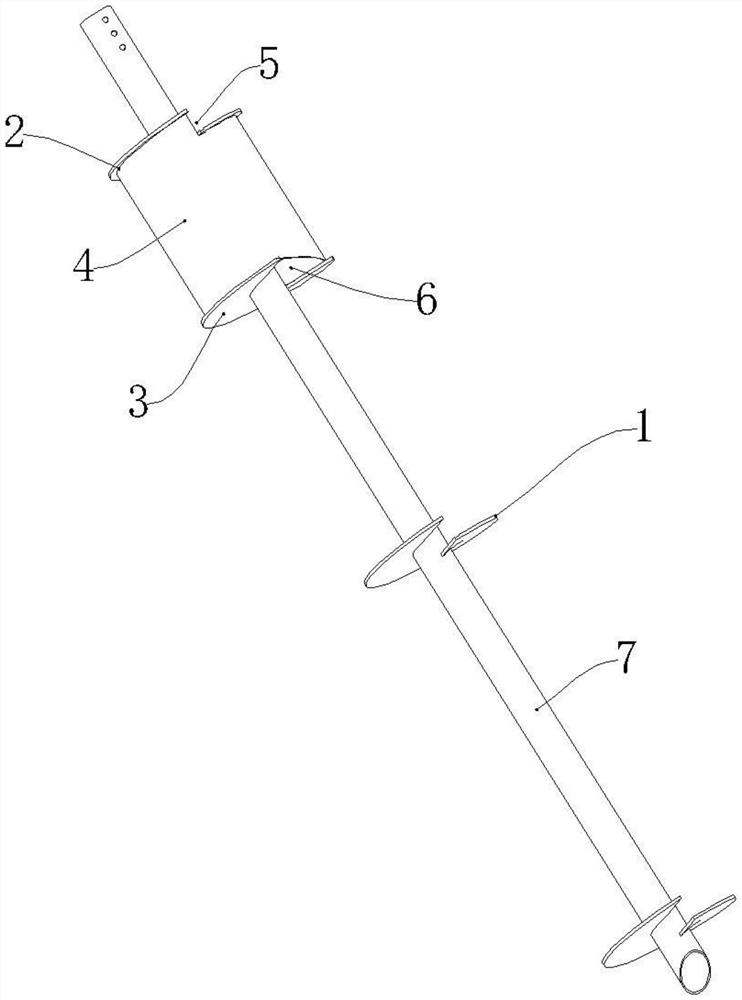

[0030] as shown in the picture Figure 4 As shown, different from Embodiment 1, the anchor rod of the spiral cartridge type composite helical anchor in this embodiment includes a guide anchor rod 7 and an extended anchor rod 8, and the spiral anchor disc 1 is arranged on the guide anchor rod 7, and the guide rod 7 is guided The anchor rod 7 is connected with the extension anchor rod 8 through a joint 9 . The spiral card cartridge is located on the extended anchor rod 8, and the spiral anchor plate 2 on the card cartridge is 1000mm from the top of the extended anchor rod 8.

[0031] Extending the anchor rod 8 is mainly used to lengthen the spiral anchor when the guide anchor rod 7 cannot meet the force requirements of the tower, so as to increase the buried depth of the spiral anchor sheet 1.

Embodiment 3

[0033]Different from Embodiment 2, the diameter of the bolt of the spiral cartridge type composite spiral anchor in this embodiment is 140mm, and the wall thickness is 13mm; the number of 2 spiral anchor plates is three, the diameter is 500mm, and the thickness is 16mm. The distance between the disks 2 is 1824mm; the diameter of the upper spiral anchor disk 2 of the cartridge and the lower spiral anchor disk of the cartridge is 500mm, the distance between the upper spiral anchor disk 2 of the cartridge and the top of the anchor rod is 1000mm, and the thickness is 16mm; the diameter of the cylinder 4 is 400mm, The wall thickness is 10mm and the length is 1000mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com