Flexible connection structure for building block infilled wall and concrete frame structure, and construction method thereof

A technology of flexible connection and frame structure, applied in the direction of building structure, walls, building components, etc., can solve the problem of insufficient out-of-plane bearing capacity of infill walls, reduce the risk of casualties and economic losses, and improve out-of-plane bearing capacity , Reduce the effect of stiffness effect and constraint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

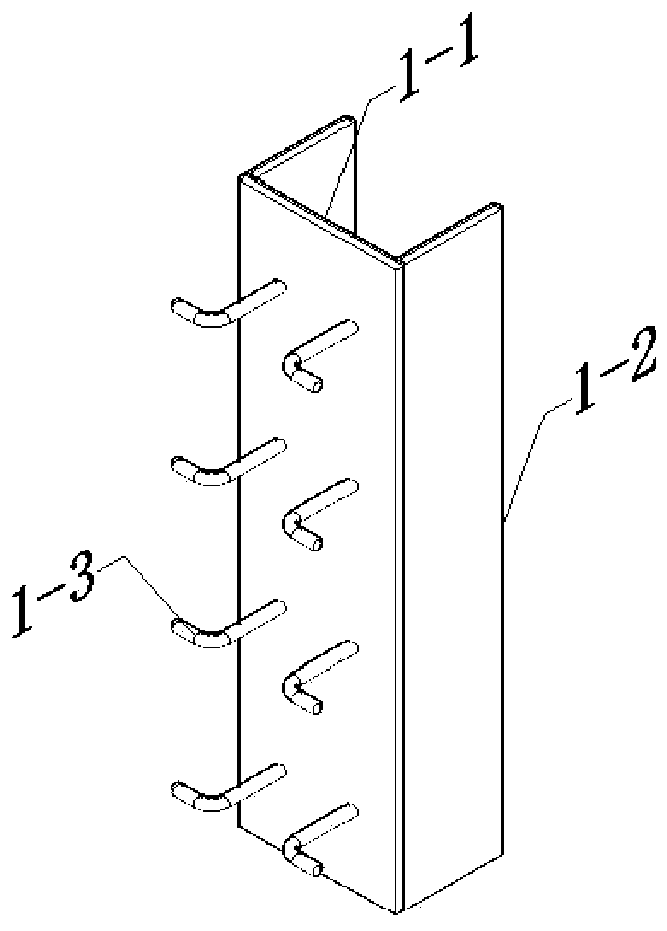

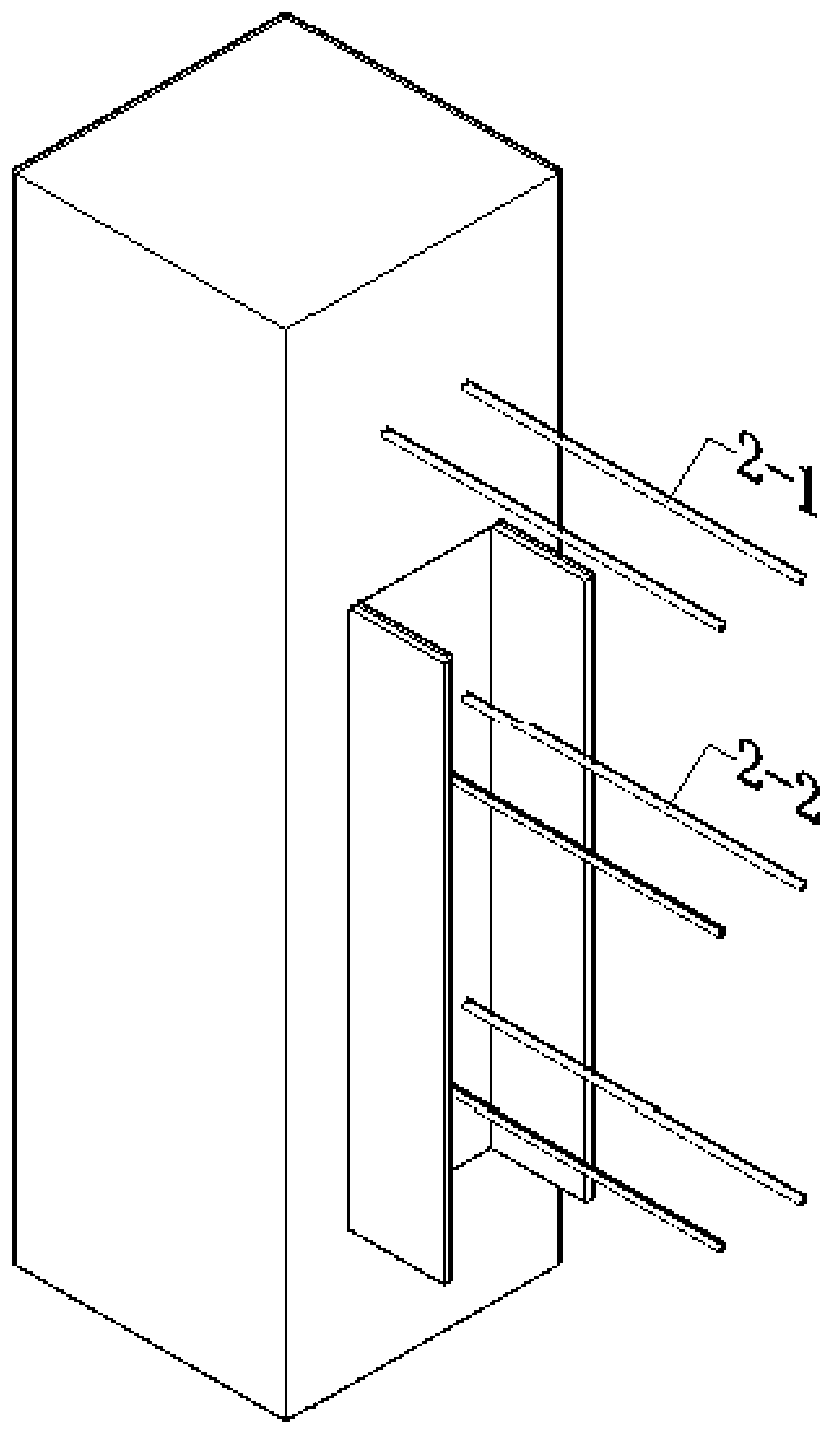

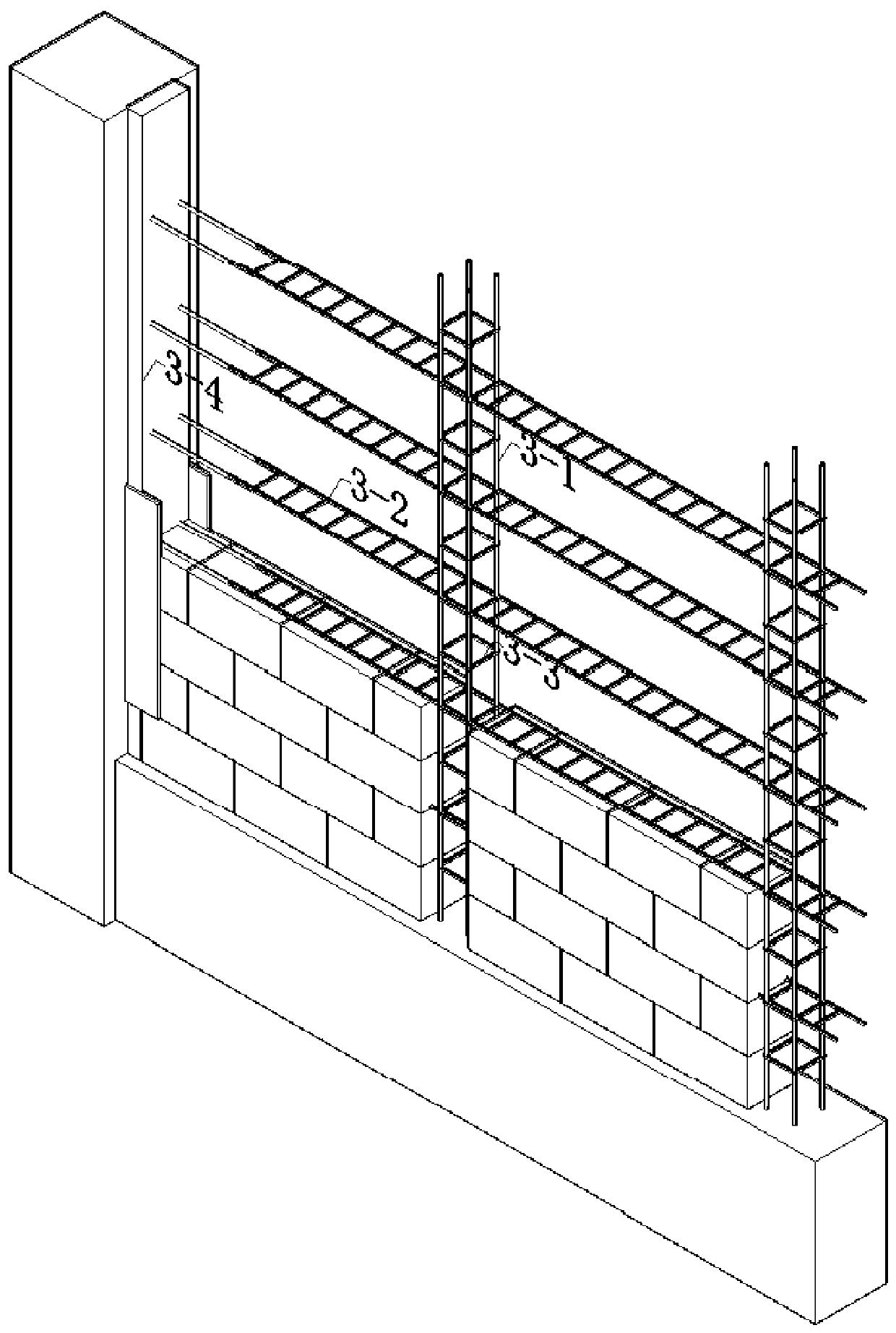

[0025] Specific Embodiment 1: The flexible connection structure between the block filling wall and the concrete frame structure in this embodiment includes a back plate 1-1, two side panels 1-2 and a plurality of anchoring steel bars 1-3. Between the block filling wall 4-3 and the concrete frame, a plurality of anchoring reinforcement bars 1-3 are arranged on one side of the backboard 1-1, the anchoring reinforcement bars 1-3 are L-shaped, and the anchoring reinforcement bars 1-3 are poured on In the concrete frame, a side wing plate 1-2 is arranged on the left and right sides of the other side plate of the back plate 1-1 to form a groove (rail) opening, and the blocks of the block filling wall 4-3 are located in the groove (Rail) In the mouth.

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the anchoring bars 1-3 on the backboard 1-1 are arranged in a rectangular array.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the back plate 1-1 and the two side panels 1-2 are all steel plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com