A travel-stationary integrated wet brake with adjustable separation gap

A wet brake, service brake technology, applied in the direction of brake type, axial brake, slack adjuster, etc., can solve the problems of difficult separation, unsuitable for high-speed and heavy-duty vehicles, and temperature rise of friction linings, so as to reduce the temperature rise. , The effect of increasing the effective friction plate area and heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

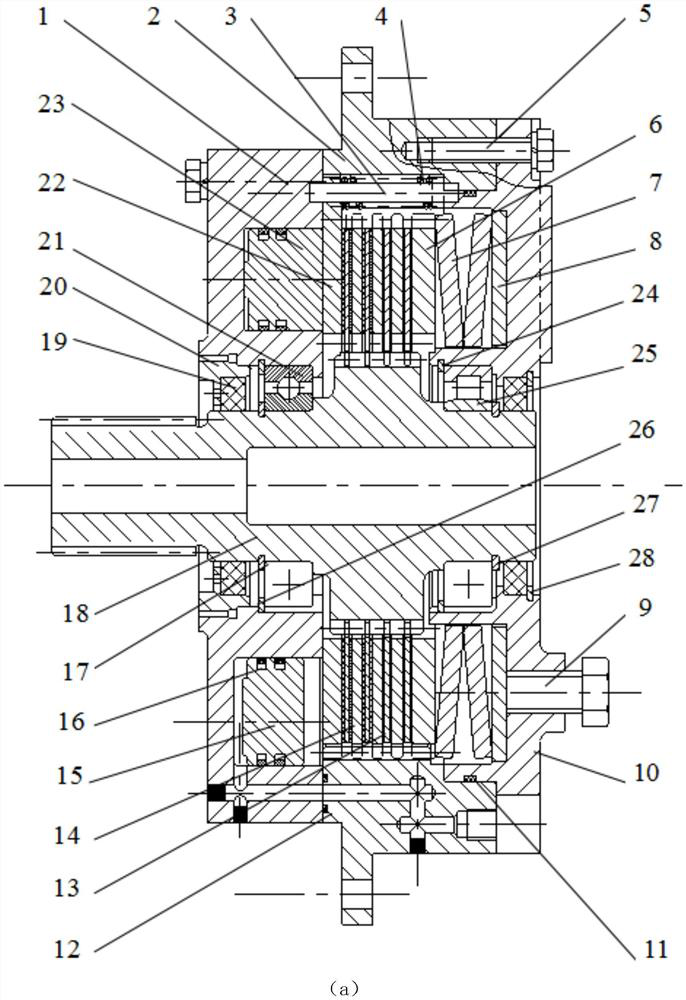

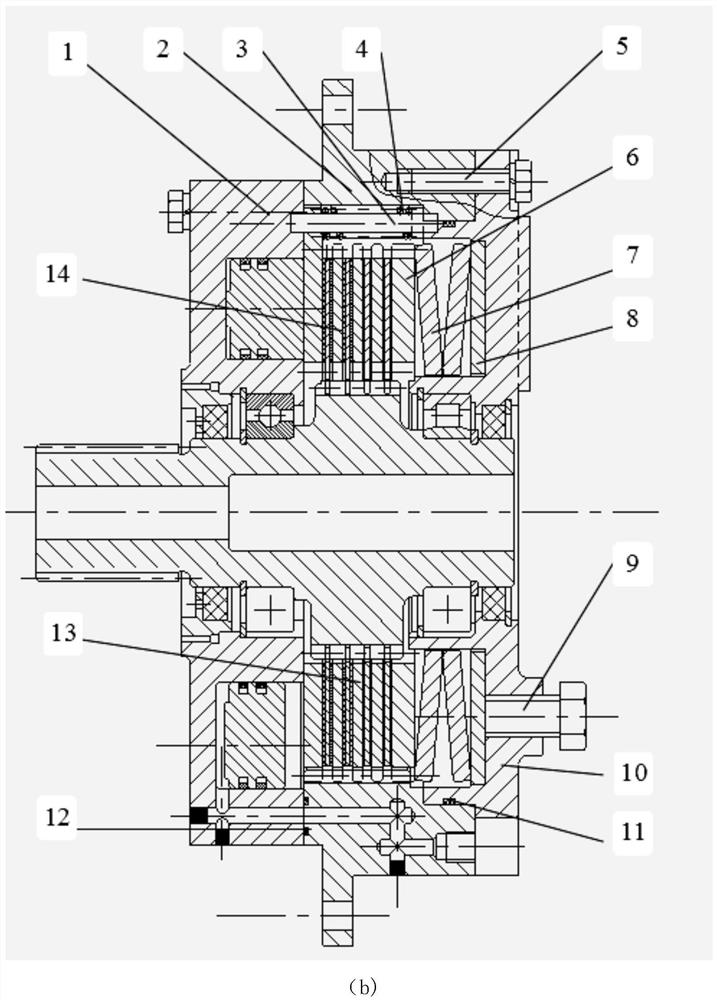

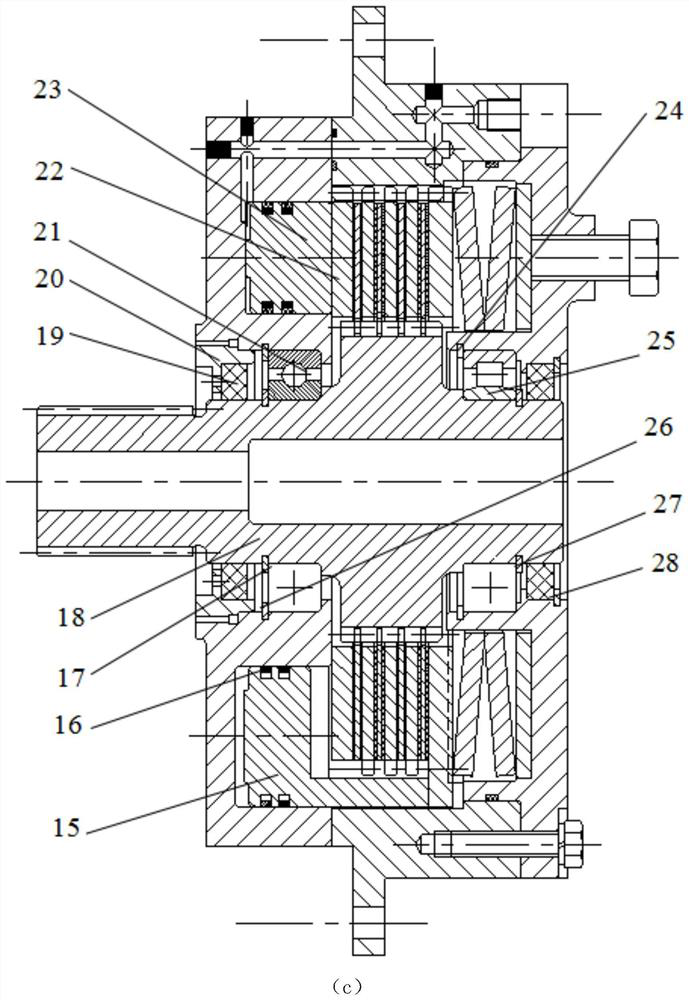

[0035] The present invention is a wet brake with adjustable separation gap, comprising a rear housing 1, an intermediate housing 2, a guide column 3, a return spring 4, a fixing bolt 5, a baffle plate 6, a disc spring 7, and a gasket 8. Adjusting bolt 9, end cover 10, large O-ring 11, small O-ring 12, internal tooth friction plate 13, external tooth friction plate 14, parking brake piston 15, sealing assembly 16, snap ring 17, input Gear shaft 18, oil seal 19, oil seal seat 20, ball bearing 21, pressure plate 22, service brake piston 23, snap ring 24, split column bearing 25, snap ring 26, snap ring 27, snap ring 28.

[0036]It is characterized in that: ball bearings, snap rings, parking brake pistons, service brake pistons and guide columns are installed on the rear housing, and the rear housing integrates the service brake pistons and parking brake pistons,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com