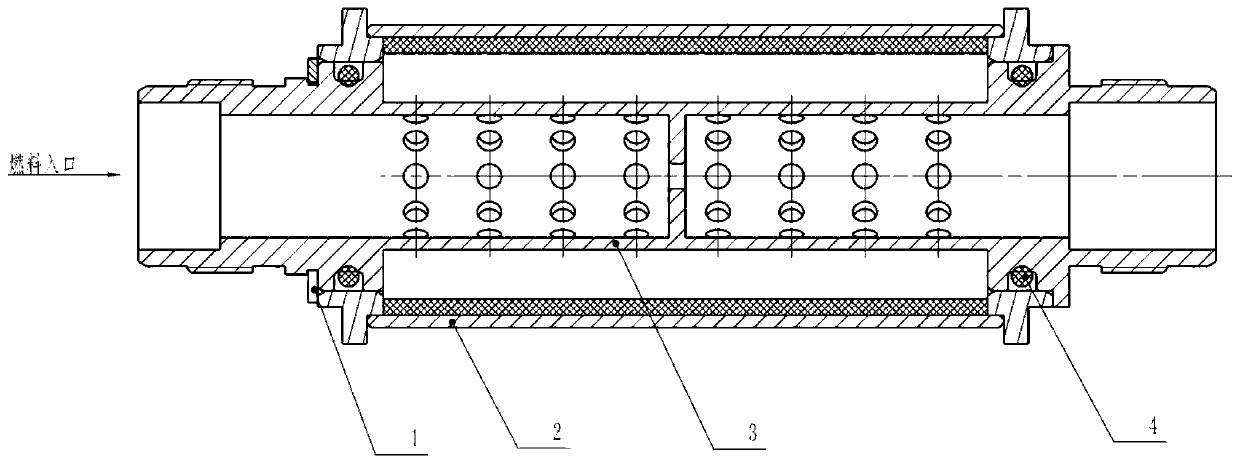

Resistance composite type pressure pulsation attenuator with length direction restraint

A pressure pulsation and composite technology, applied in the direction of fluid flow, engine components, machines/engines, etc., can solve the problems of large structural size, large pressure loss and narrow attenuation frequency band of pressure pulsation attenuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

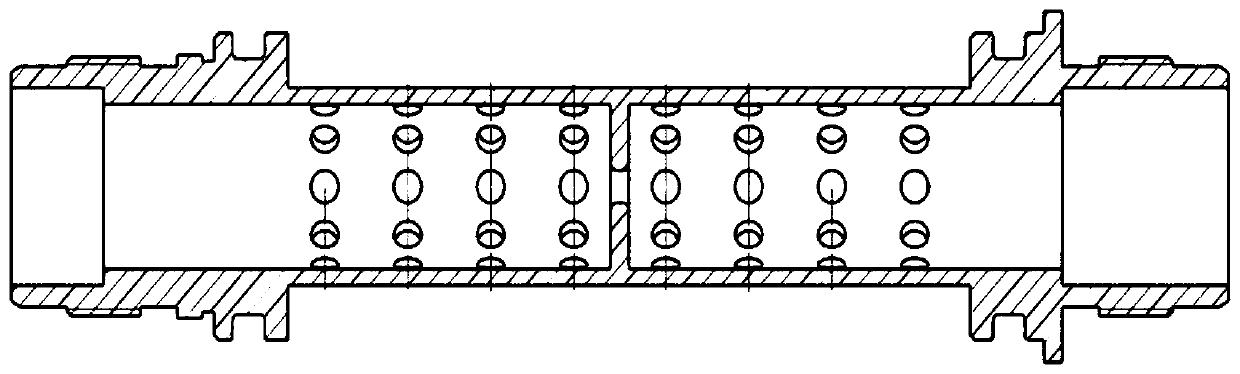

[0019] Pressure pulsation attenuators include resistive attenuators and resistive attenuators. Resistive attenuators use elastic materials to attenuate pressure pulsations. The resistive materials are fixed on the inner wall of the fluid channel or arranged in a certain way in the pipeline to form The elastic wall, when the pressure pulsation enters the attenuator, the resistive material will convert part of the pulsation pressure into heat energy and dissipate it, so as to achieve the purpose of attenuating the pressure pulsation, and has a good attenuation effect in the medium and high frequency range. The resistance attenuator does not directly absorb sound energy, but uses the interface that utilizes the sudden change of pressure pulsation characteristics in the pipeline to reflect part of the pulsation energy back to the pulsation source, which is suitable for eliminating middle and low frequency noise. These two pressure pulsation attenuators have their own advantages, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com