Lamp structure

A technology of lamps and card slots, applied in gardening tools/equipment, lighting and heating equipment, applications, etc., can solve the problems of glue temperature, humidity influence, troublesome installation and disassembly, uniform arrangement of unfavorable light sources, etc., to prevent deformation and occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

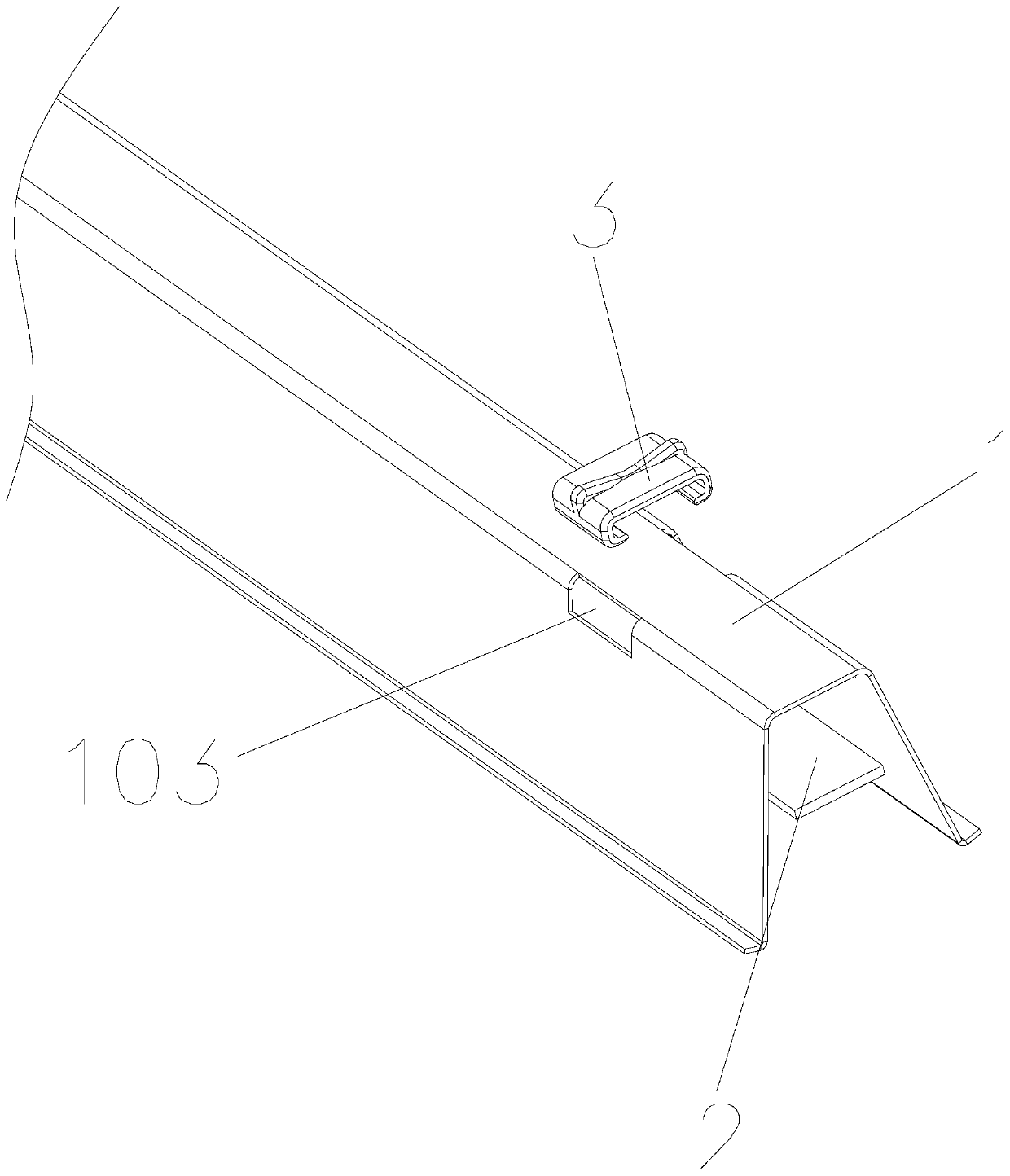

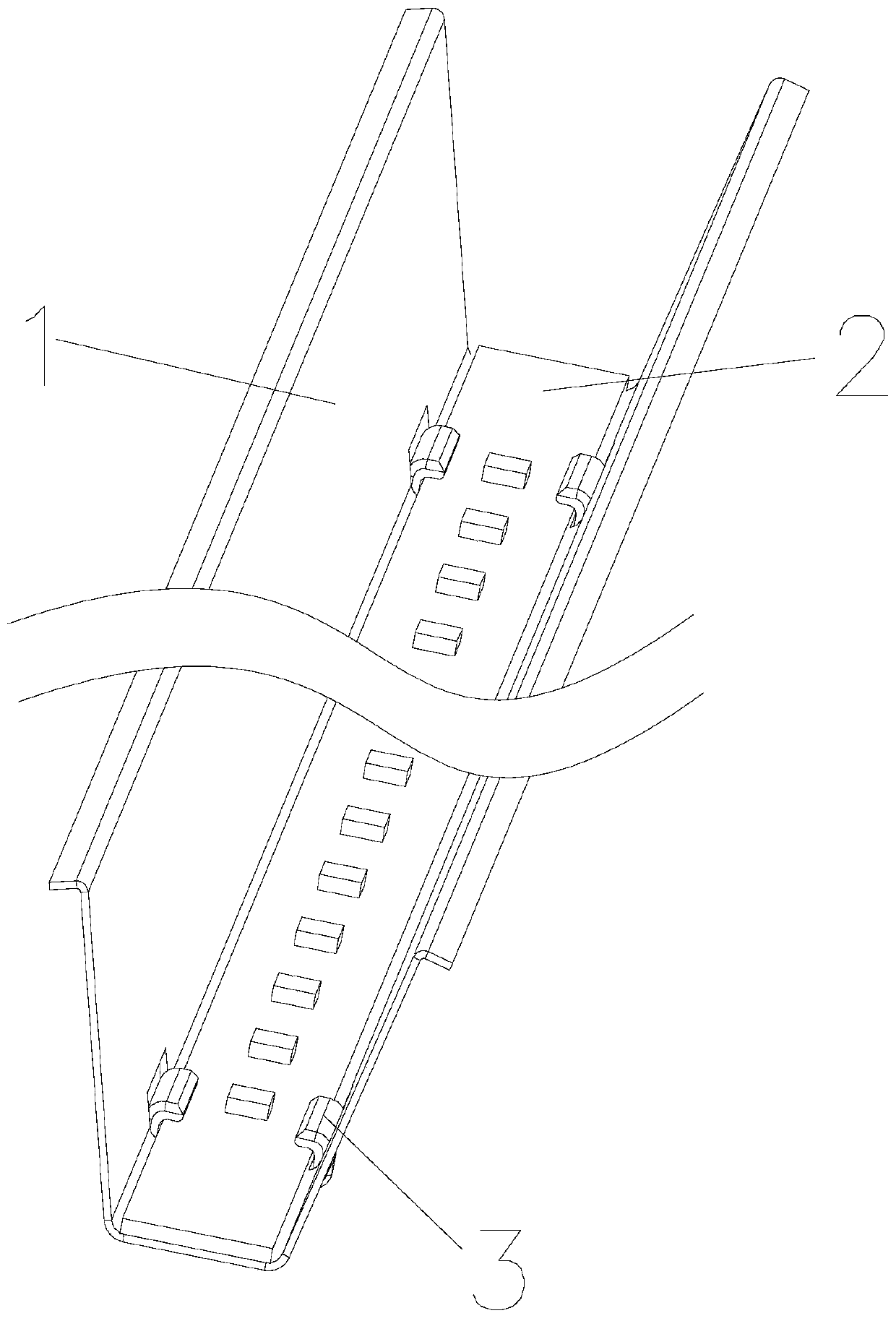

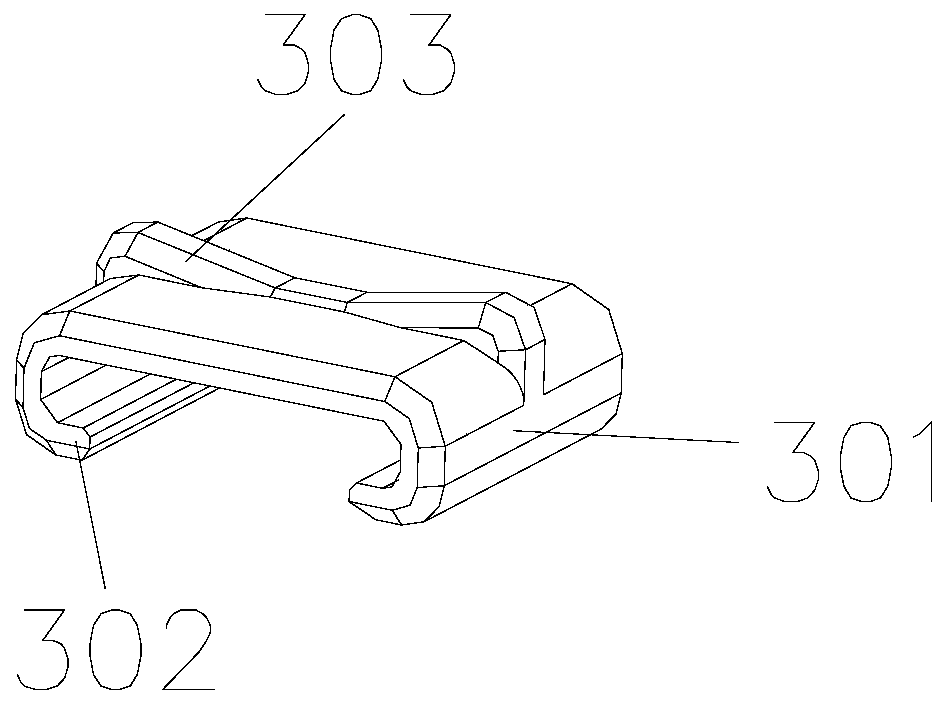

[0038] see Figure 1-Figure 6 , a light fixture structure in this embodiment, including a reflector 1 and a light source board 2, and also includes a detachable buckle device 3 with at least two clamping edges 301, and at least two buckles for installing on the reflector 1 The clamping groove 103 of the device 3 , the clamping edge 301 of the clamping device 3 is inserted into the clamping groove 103 , and the light source board 2 is fixed between the clamping edge 301 and the gap formed between the reflecting surface of the reflector 1 . Specifically, the ends of the two card edges 301 of the buckle device 3 are respectively provided with a card point 302 for fixing the light source board 2 to prevent the light source board 2 from falling off. In other embodiments, the ends of the two card edges 301 are respectively provided with The fixed positions of the two clamping points 302 are more flexible and adjustable, which are not shown in the drawings. The card slot 103 is a ca...

Embodiment 2

[0043] see Figure 1-Figure 5 , Figure 7, a light fixture structure in this embodiment, including a reflector 1 and a light source board 2, and also includes a detachable buckle device 3 with at least two clamping edges 301, and at least two buckles for installing on the reflector 1 The clamping groove 103 of the device 3 , the clamping edge 301 of the clamping device 3 is inserted into the clamping groove 103 , and the light source board 2 is fixed between the clamping edge 301 and the gap formed between the reflecting surface of the reflector 1 . Specifically, the ends of the two card edges 301 of the buckle device 3 are respectively provided with a card point 302 for fixing the light source board 2 to prevent the light source board 2 from falling off. In other embodiments, the ends of the two card edges 301 are respectively provided with The fixed positions of the two clamping points 302 are more flexible and adjustable, which are not shown in the drawings. The card slot...

Embodiment 3

[0048] see Figure 1-Figure 5 , Figure 8 , a light fixture structure in this embodiment, including a reflector 1 and a light source board 2, and also includes a detachable buckle device 3 with at least two clamping edges 301, and at least two buckles for installing on the reflector 1 The clamping groove 103 of the device 3 , the clamping edge 301 of the clamping device 3 is inserted into the clamping groove 103 , and the light source board 2 is fixed between the clamping edge 301 and the gap formed between the reflecting surface of the reflector 1 . Specifically, the ends of the two card edges 301 of the buckle device 3 are respectively provided with a card point 302 for fixing the light source board 2 to prevent the light source board 2 from falling off. In other embodiments, the ends of the two card edges 301 are respectively provided with The fixed positions of the two clamping points 302 are more flexible and adjustable, which are not shown in the drawings. The card slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com