Waterproofness detection device for engineering building materials and detection method thereof

A technology for building materials and engineering, applied in the field of waterproof detection devices for engineering building materials, can solve problems such as low detection accuracy, and achieve the effects of improving experimental results, improving accuracy and scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

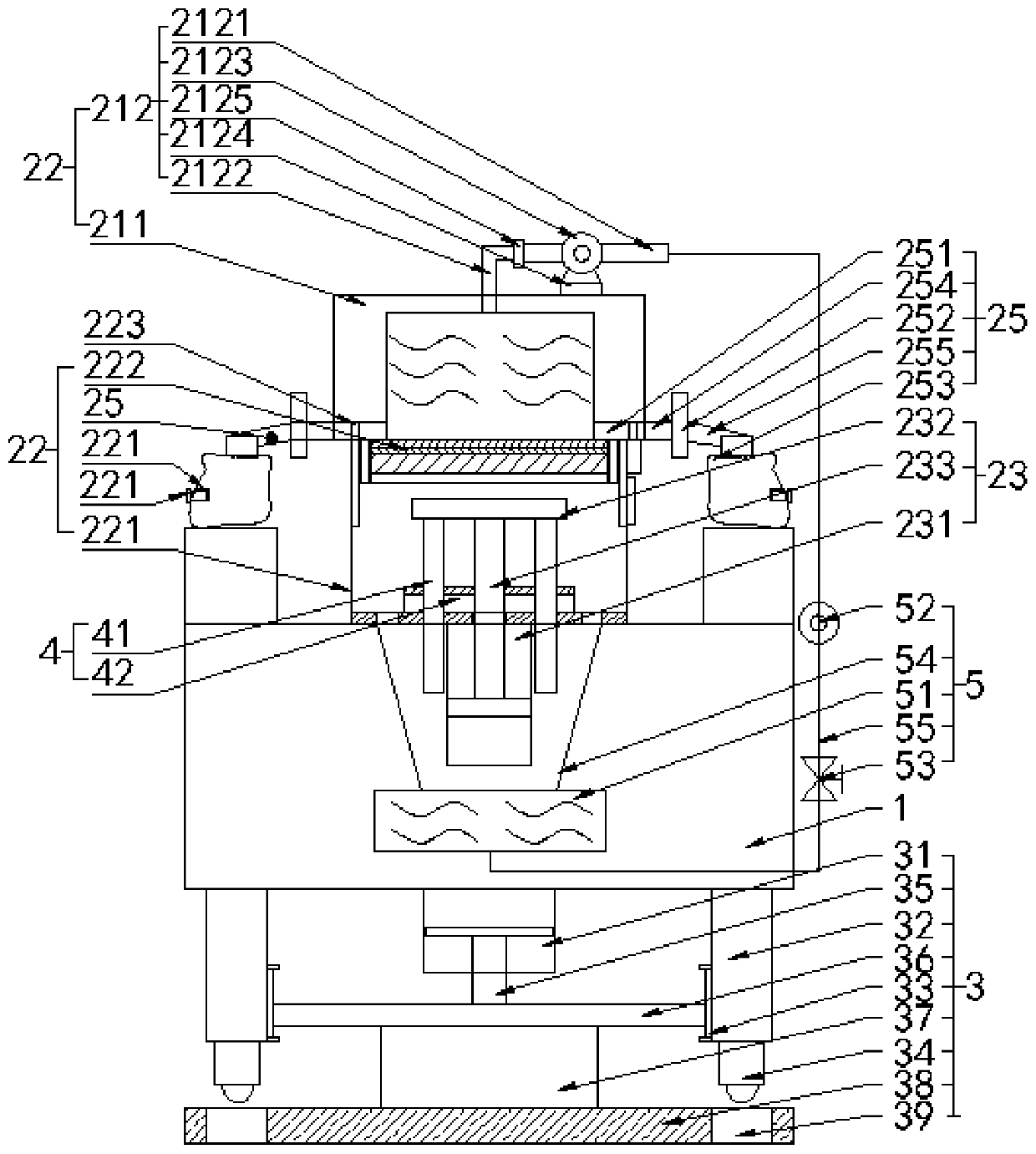

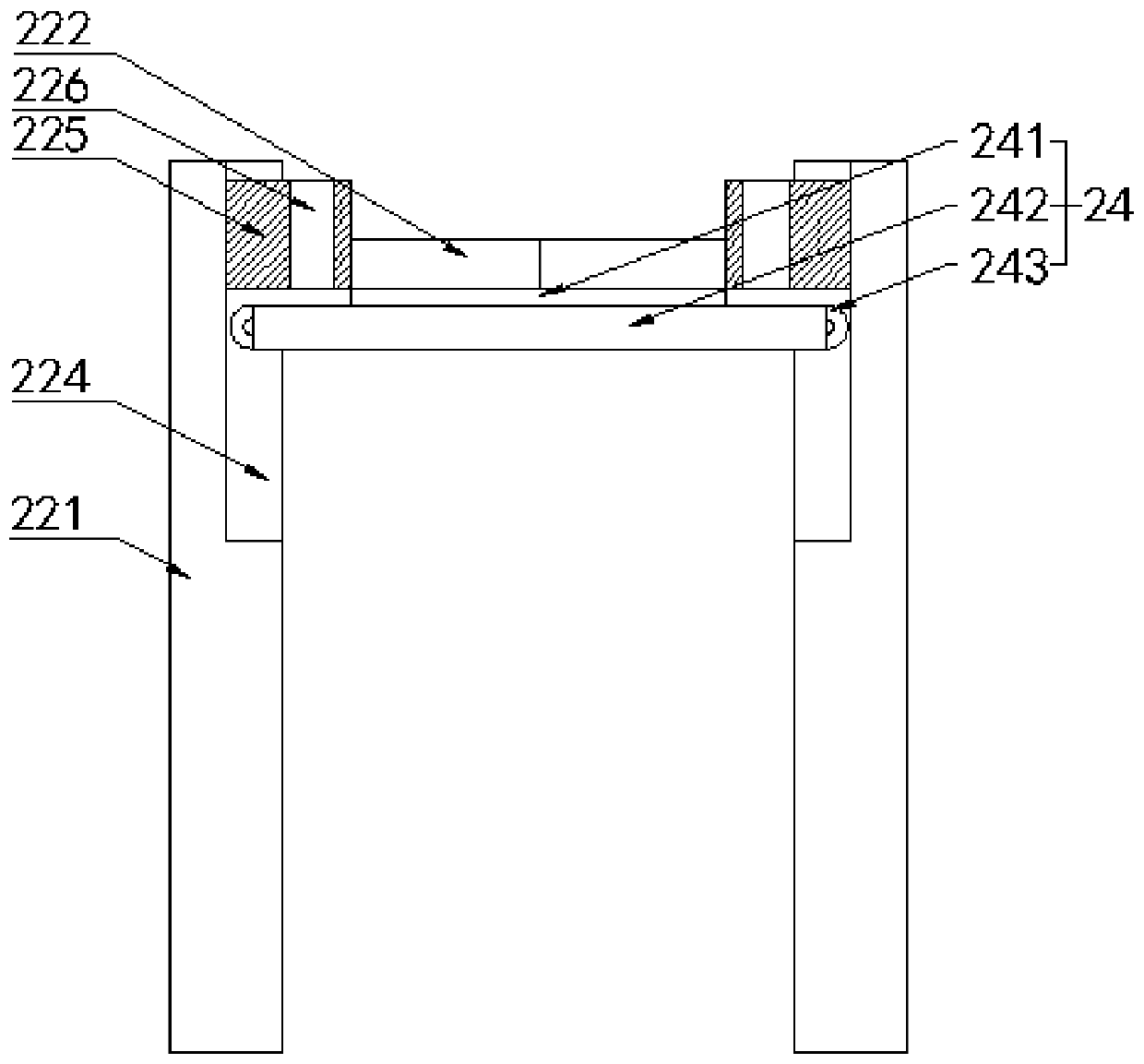

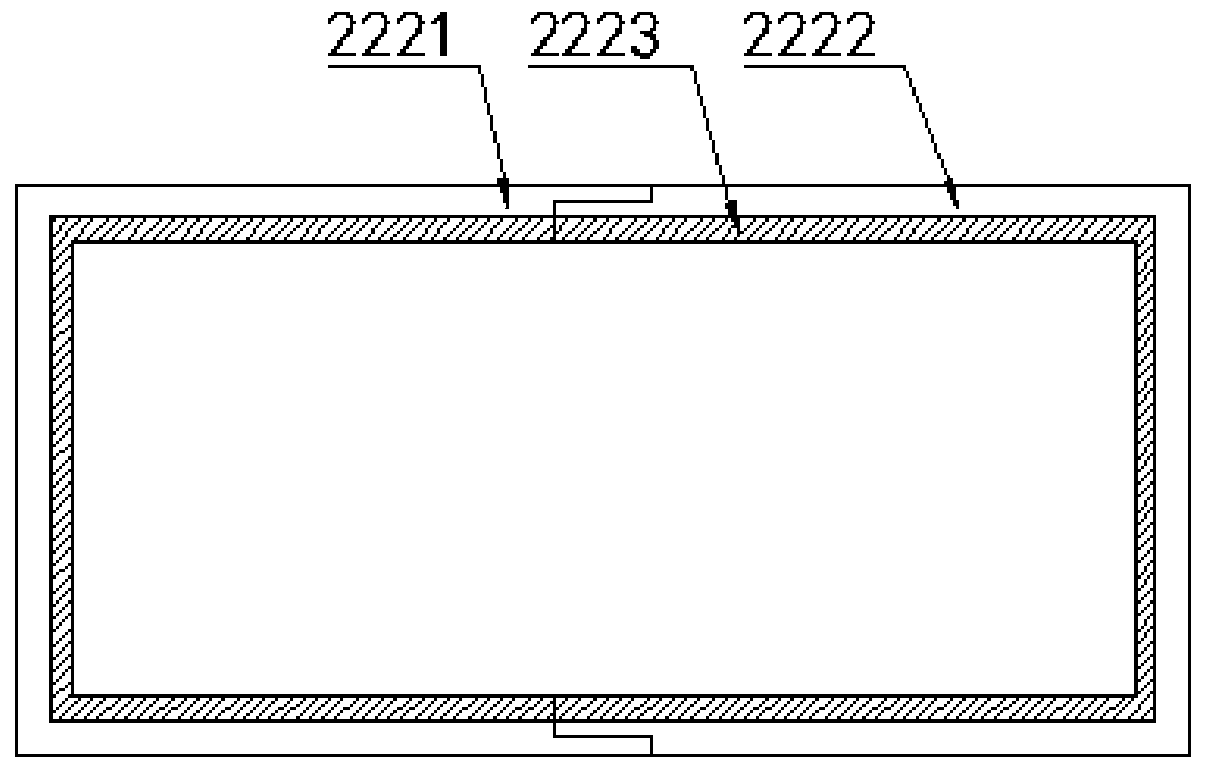

[0036] Such as Figure 1-Figure 3 As shown, the present invention discloses a waterproof detection device for engineering building materials. In the embodiment of the present invention, it includes a workbench 1 and a detection component 2 fixedly installed on the workbench 1 for detecting the waterproof effect of building materials; The detection assembly 2 includes a simulated water flow module 21, a clamping module 22, an extrusion module 23 and a detection module 24; The delivery unit 212; the delivery unit 212 is fixedly installed on the top of the water storage tank 211, and the output end of the delivery unit 212 communicates with the water storage tank 211; the bottom plate of the water storage tank 211 is provided with an opening for installation; The clamping module 22 is arranged at the bottom of the water storage tank 211; the clamping module 22 includes a water collection box 221 and an installation fixture 222 for clamping building material samples; The gap betw...

Embodiment 2

[0043] Embodiment 2, the difference with embodiment 1 is

[0044] Such as figure 1 As shown, in the embodiment of the present invention, the bottom of the workbench 1 is provided with a moving assembly 3 for conveniently moving the device itself; Plate 32; the second cylinder 31 is fixedly installed in the middle of the bottom surface of the water collection box 221, each fixed plate 32 is provided with a slideway 33 on the side facing the second cylinder 31, and the bottom of the fixed plate 32 is movably connected with a rolling element 34, the air rod 2 35 of the second cylinder 31 is fixedly connected with a lifting plate 36 at one end away from the water collection tank 221; the lifting plate 36 is slidably connected with the slideway 33 on the fixed plate 32; the bottom surface of the lifting plate 36 A support block 37 is fixedly installed, and the end of the support block 37 away from the lifting plate 36 is provided with a support base 38; and the support base 38 is ...

Embodiment 3

[0049] Embodiment 3, the difference with embodiment 1 is

[0050] Such as figure 1 As shown, in the embodiment of the present invention, the bottom plate of the water collection tank 221 is installed with a stabilizing assembly 4 for stabilizing the longitudinal drive of the drive cylinder 231; The stabilizing bar 41 on the extrusion plate 232; one end of the stabilizing bar 41 is fixedly installed on the extruding plate 232, and the other end passes through the bottom plate of the water collecting box 221; the stabilizing bar 41 and the air bar one 233 are connected with the water collecting box 221 The junction of the bottom plate is provided with a baffle plate 42 for preventing water leakage.

[0051] By providing a stabilizing component, the driving cylinder can run more stably, ensuring that the extrusion plate can be evenly stressed during the extrusion process, further preventing water from seeping out along the side of the building material sample, and further improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com