Abnormality detection method, projection device, and computer-readable storage medium

A technology for abnormality detection and projection equipment, which is applied in the field of detection and can solve problems such as the inability to determine the heat dissipation of the light source in time, and the easy damage of the light source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

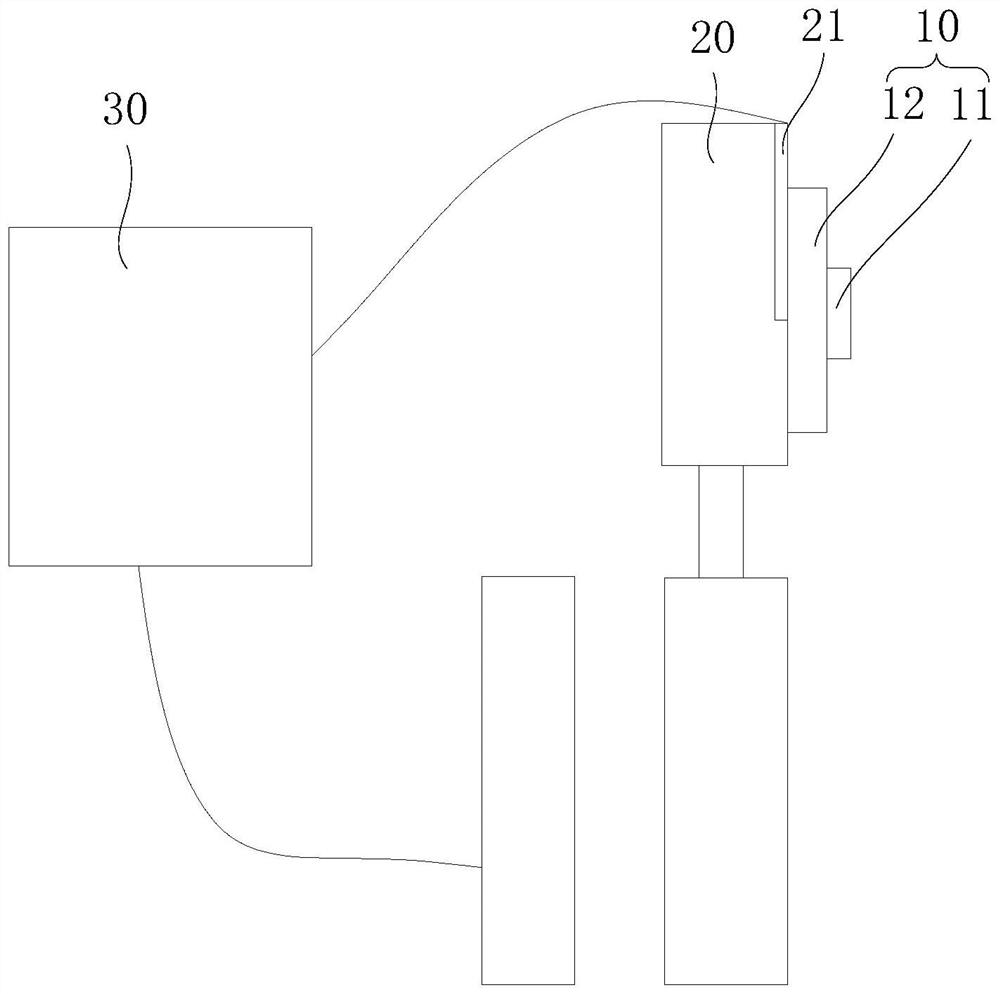

[0058] Please refer to figure 2 , the projection device includes a light source, a first temperature sensor and a heat sink, the light source includes a light source body and a light source substrate, the heat sink is arranged on a side of the light source substrate away from the light source body, the first A temperature sensor is used to measure the temperature of the heat sink, and the abnormal detection method includes:

[0059] S100, acquiring the temperature of the heat sink according to the first temperature sensor;

[0060] Wherein the first temperature sensor is used to detect the temperature on the heat sink, specifically, the first temperature sensor can be a contact temperature sensor or a non-contact temperature sensor, specifically, when the first temperature sensor is In the case of a contact temperature sensor, the first temperature sensor may be a thermocouple or a thermistor, and in the case of a non-contact temperature sensor, the first temperature sensor ...

no. 2 example

[0068] In the first embodiment, the S100 includes:

[0069] After the light source is started, the step of acquiring the temperature of the heat sink detected by the first temperature sensor is performed.

[0070] Wherein, when the light source is in a non-working state, the light source does not generate heat, so there is no need to measure the temperature of the heat sink, and when the light source is activated, the projection device receives the light source from the light source start message, so as to start to obtain the temperature of the heat sink of the heat sink through the first temperature sensor.

no. 3 example

[0072] In the first embodiment, the reference temperature is a preset temperature, specifically, the preset temperature refers to a temperature curve or a temperature value pre-stored by the projection device for detecting the abnormal state.

[0073] When the preset temperature is a temperature change curve within a certain time range, the projection device compares with the temperature change curve according to the temperature change of the heat sink, and obtains the heat dissipation at different times The difference between the temperature of the sheet and the temperature change curve.

[0074] When the maximum value of the difference is greater than the preset difference, it means that the light source is in an abnormal state of heat dissipation; when the maximum value of the difference is smaller than the preset difference, it means that the light source is in an abnormal state of heat dissipation state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com