Residual network rolling bearing fault diagnosis method based on time-frequency analysis

A fault diagnosis, rolling bearing technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of gradient explosion, gradient disappearance, limited diagnostic accuracy, etc., to achieve high accuracy, convenient Adjustment, the effect of facilitating accurate diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0036] The residual network rolling bearing fault diagnosis method based on time-frequency analysis of the present invention comprises the following steps:

[0037] S1. Vibration signal data collection and processing;

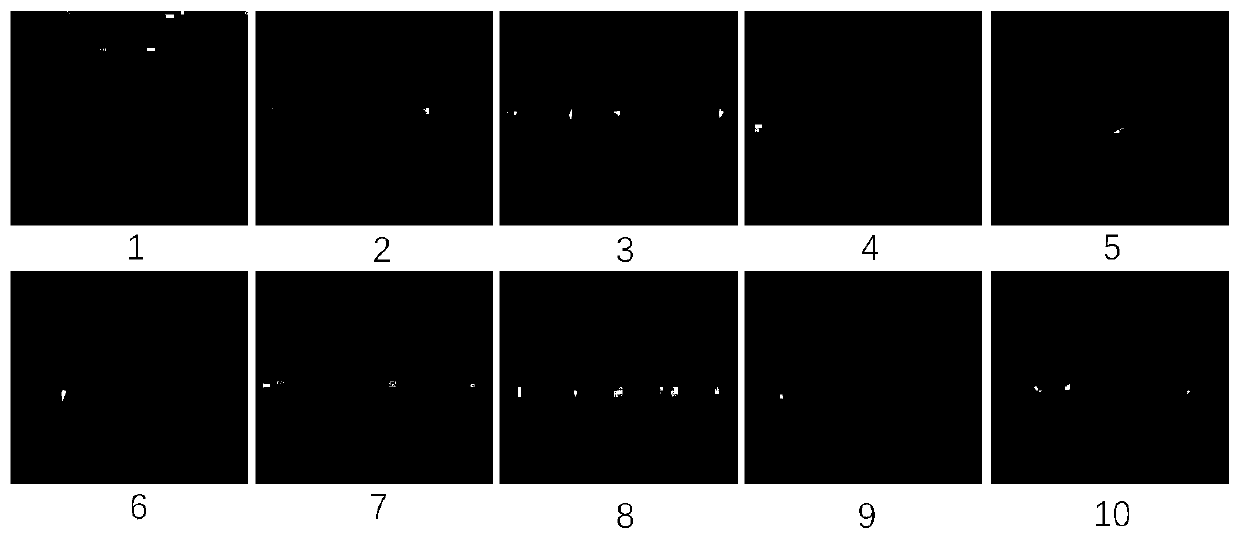

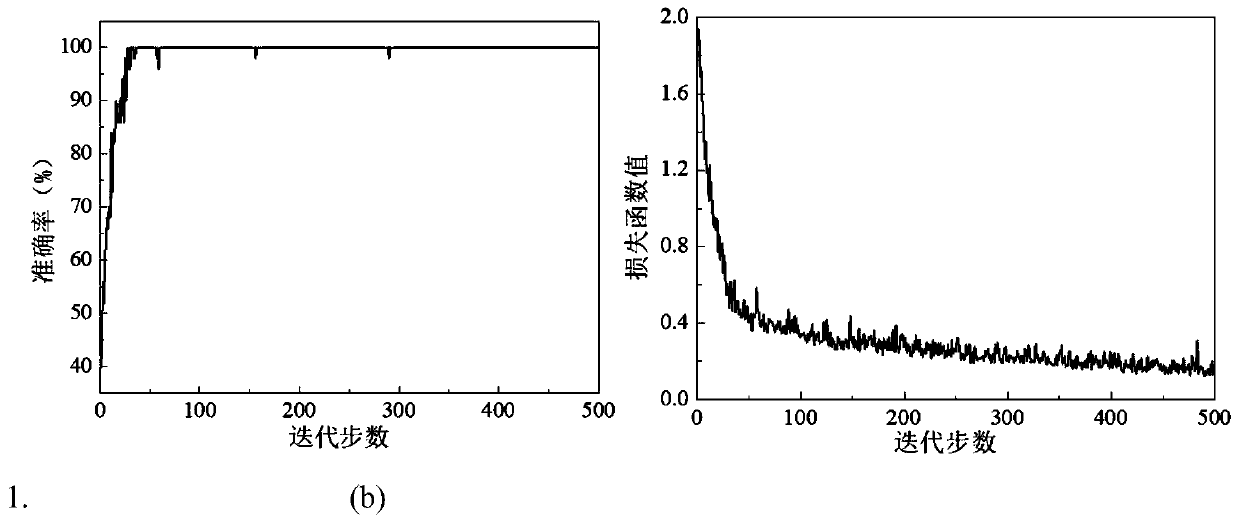

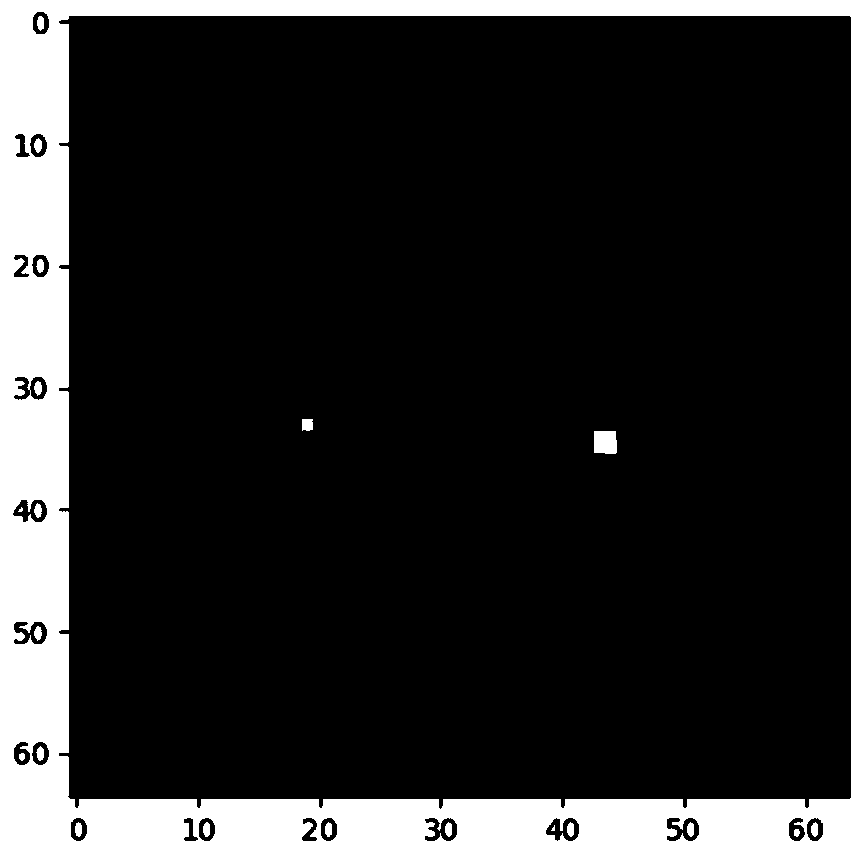

[0038] The data set used this time is the bearing data set of the Western Reserve University in the United States. In this example, a total of 10 fault types are set, as shown in Table 1. Then the data of each fault type is divided into 2048×1 samples, and finally each sample is converted into a 64×64 time-frequency grayscale image by short-time Fourier transform.

[0039] Given a window function γ(t) with a very short time width, let the window slide, then the short-time Fourier transform of the signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com