Experimental system for simulating impact presplitting and cutting

An experimental system and experimental technology, applied in the field of experimental systems, can solve the problems of manual cleaning, low reliability of experimental results, and poor safety, and achieve the effect of preventing safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

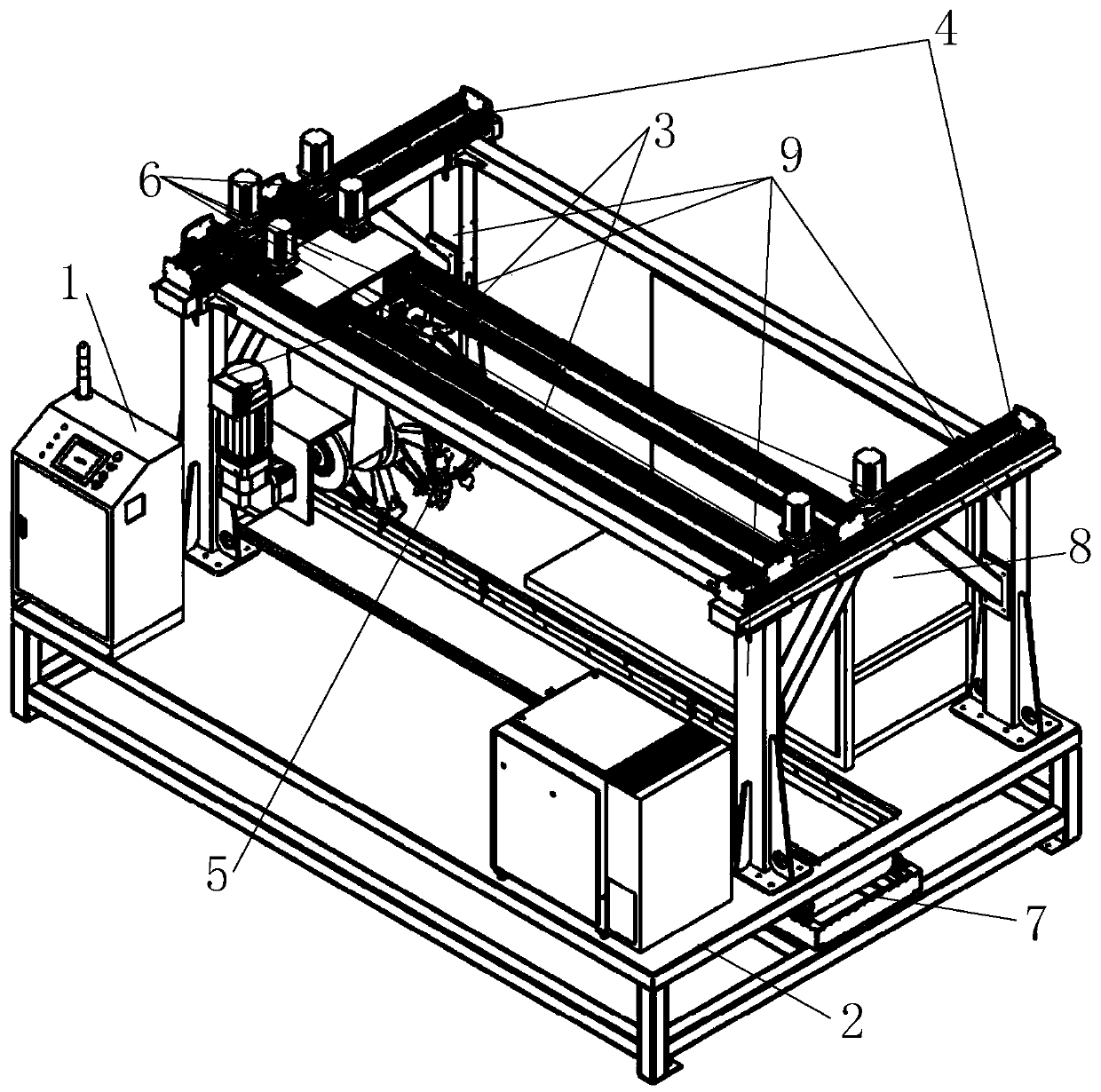

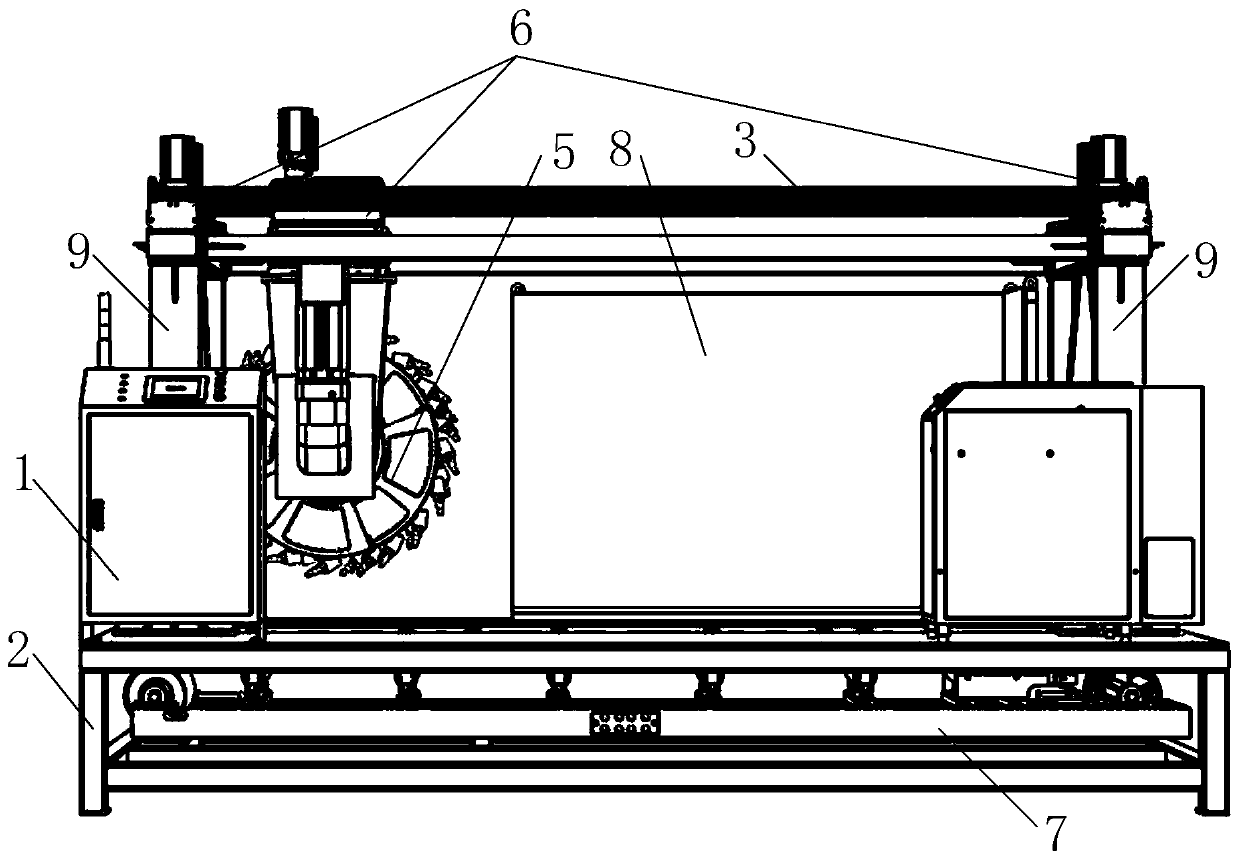

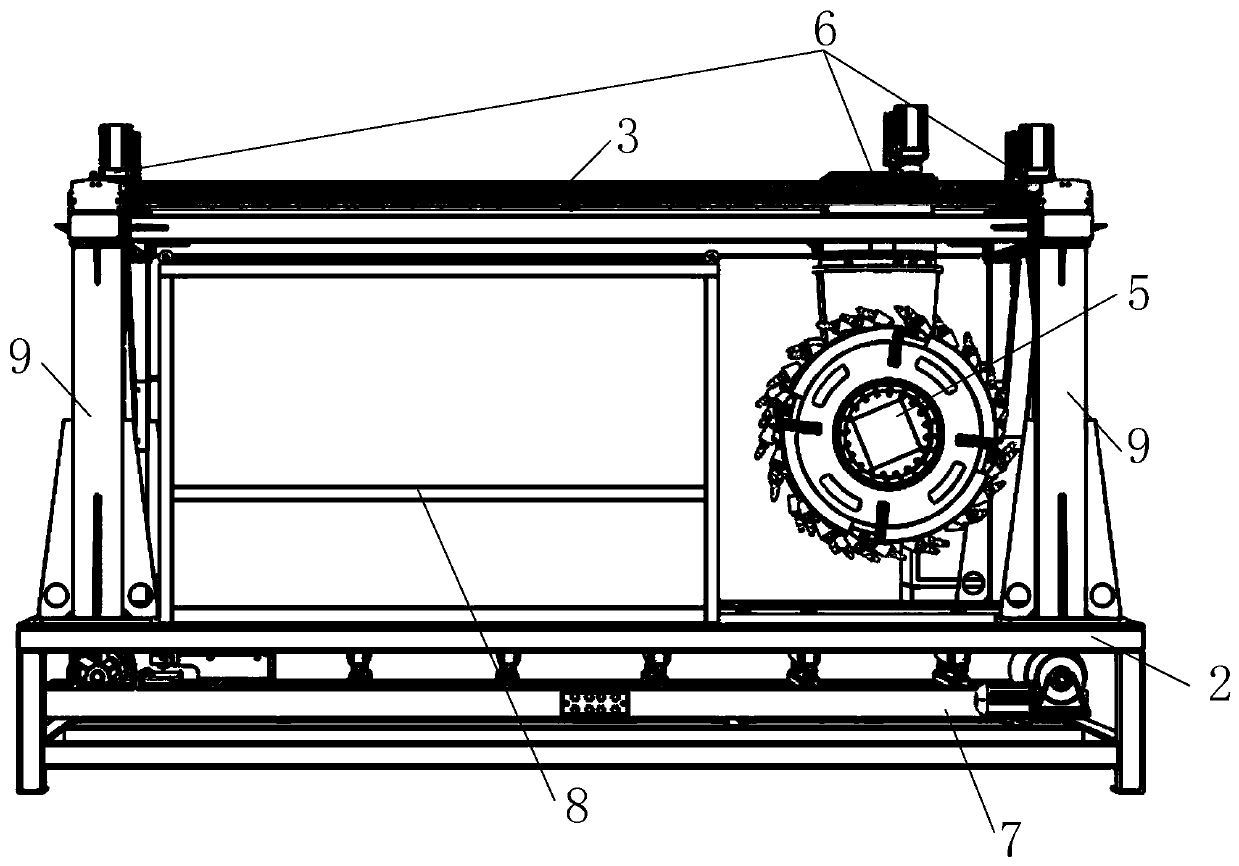

[0017] Such as figure 1 It is a schematic diagram of the overall structure of an experimental system for simulating impact pre-cracking and cutting of the present invention, figure 2 , image 3 and Figure 4 It is the front view, rear view and right view of an experimental system for simulating impact pre-splitting and cutting in the present invention, and the purpose is to express the overall structure of the system more accurately. An experimental system for simulating impact pre-splitting and cutting, including a simulated shearer cutting part 5, the simulated shearer cutting part 5 moves on the length guide rail 3 and the depth guide rail 4 through the slider 6, and realizes the simulation For the positioning work of the cutting part 5 of the shearer, the guide rail is connected with the support device 2 through the guide rail column 9 to realize the fixing work of the guide rail. An experimental system for simulating impact pre-splitting and cutting, using the compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com