Precise troubleshooting device for slip rope magnetic flux leakage detection fault region

A technology of magnetic flux leakage detection and fault area, applied in the direction of material magnetic variation, etc., can solve the problems of corrosion, uneven force of sliding cable, wear of steel cable strands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

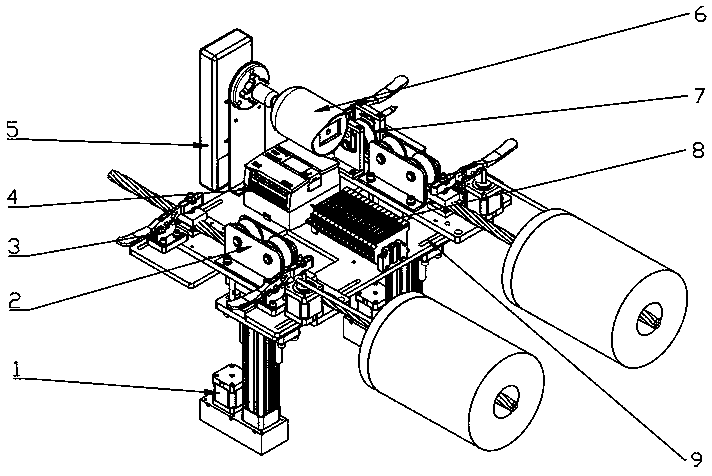

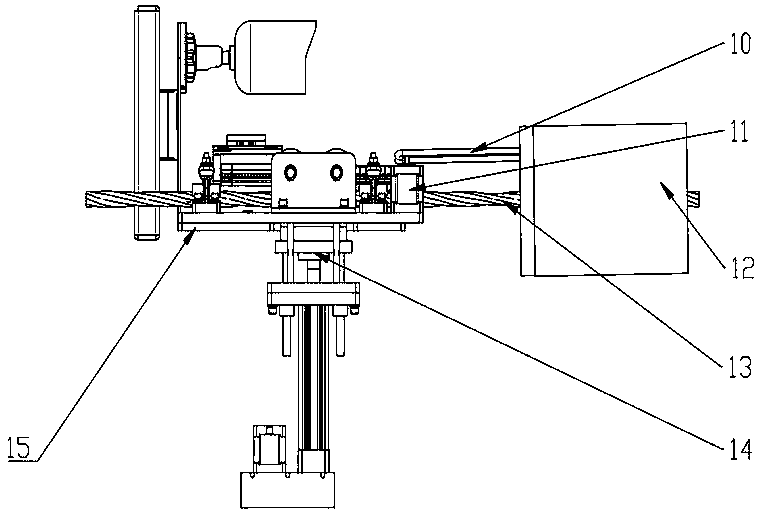

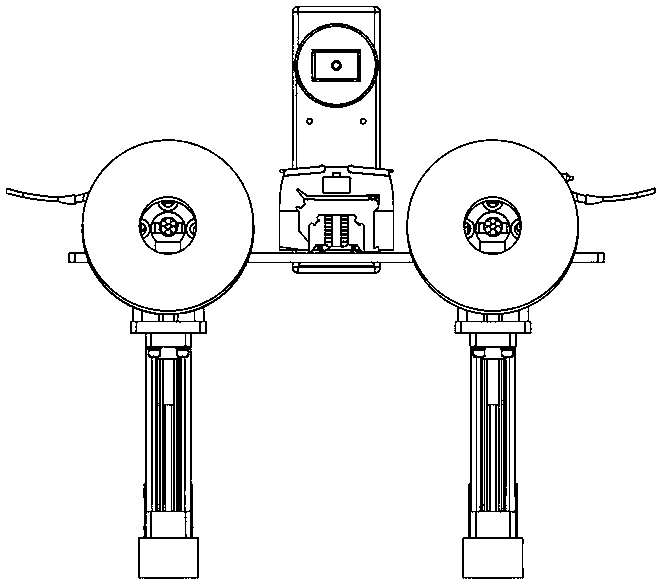

[0027] like figure 1 , figure 2 and image 3 As shown, this embodiment includes an electric cylinder 1, a pulley assembly 2, a crimping fixture 3, a power supply 4, a wireless bridge 5, a camera 6, a speed measuring wheel 7, an adaptive hardware circuit 8, a guide rail 9, a drag cable 10, and a motor 11 , A magnetic flux leakage detection device 12 , a pressing plate 14 , and a mounting plate 15 . The guide rails 9 are symmetrically distributed on both sides of the mounting plate 15. When installing the magnetic flux leakage detection device for the slide cable, the installation can be adjusted within a certain range according to the width between the cable cables 13 of the slide cable. The crimping clamps 3 clamp the steel cables 13 on both sides of the slide cables respectively, and the mounting plate 15 is fixed on the steel cables 13 of the slide cables at the initial stage. After the zipline magnetic leakage detection device is installed and debugged correctly, open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com