Blisk blade section online measurement path planning method

A technology for measuring paths and blisks, which is applied to instruments, digital control, control/regulation systems, etc., can solve the problems of increasing the time taken up by machine tools and three-coordinate equipment, the workload of operators, high enterprise costs, and low efficiency of path planning. , to achieve the effect of improving machine tool utilization, improving production efficiency, and high path planning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The application will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the application and implement it, but the examples given are not intended to limit the application.

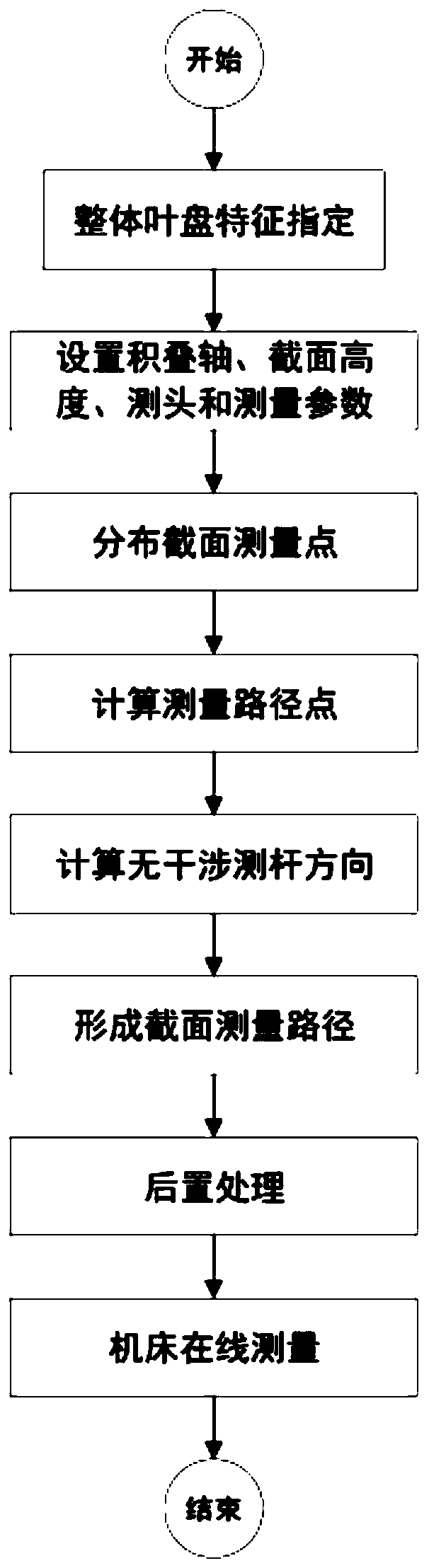

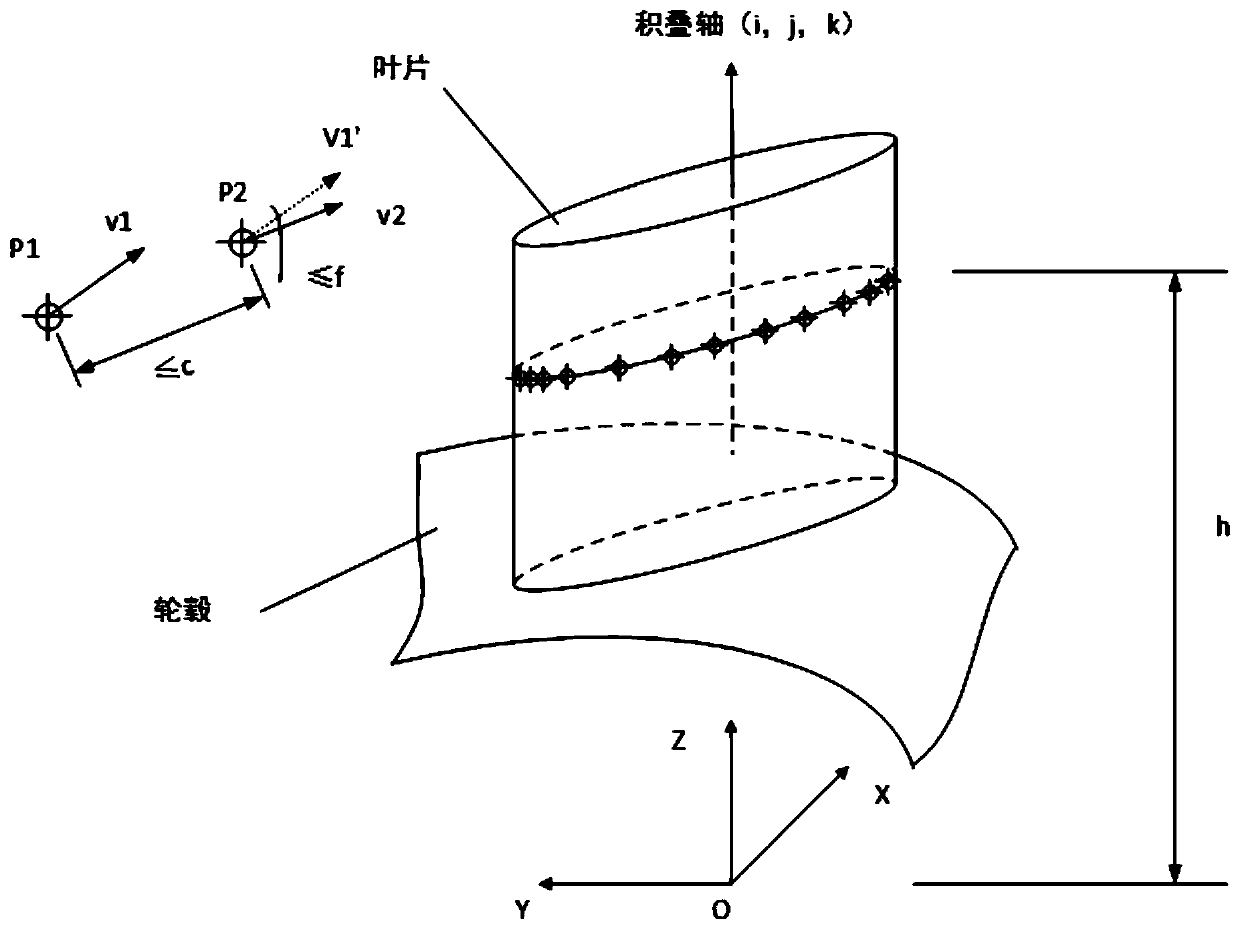

[0035] The present application provides an online measurement path planning method for blade cross section of an integral blisk. The method is to automatically plan a non-interference cross section measurement path according to blade stacking axis, set section height, probe and measurement parameters.

[0036] Preferably, the method includes,

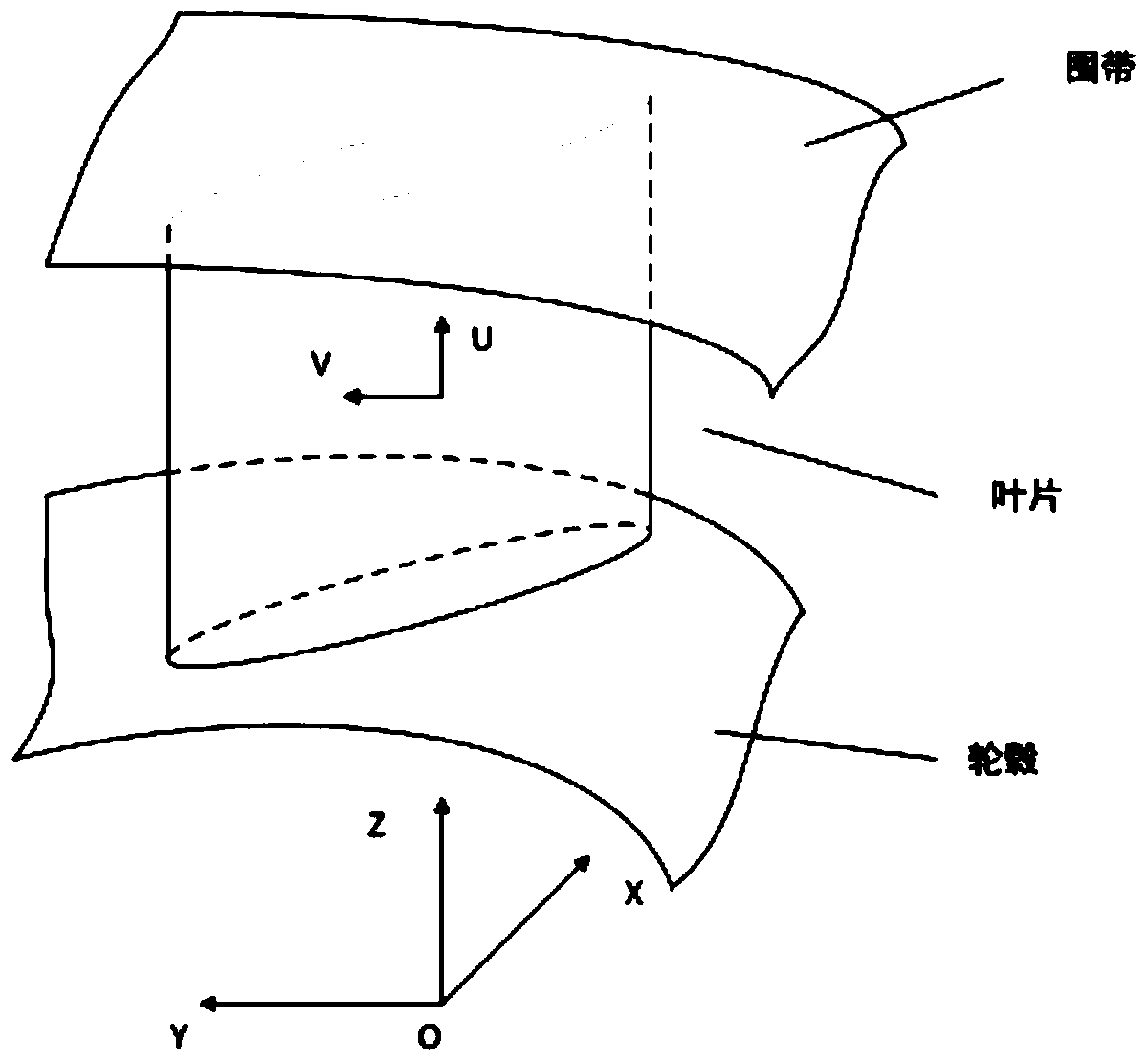

[0037] (1) Import the overall blisk geometry model in igs or step format, specify the blade, shroud and hub surface of the blisk, define the basic features of the blisk as "blade", "shroud" and "hub", and standardize the blade In the U and V directions, the X-axis of the model coordinate system is the direction from the leading edge of the blade to the trail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com