An interconnect structure and method for preparing the same

一种内连线、复数的技术,应用在内连线结构及其制备领域,能够解决铜导线与钨介层窗对位裕度缩小、钨接触制备困难、短路的风险增加等问题,达到提升制程裕度、降低短路的风险、高对位裕度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

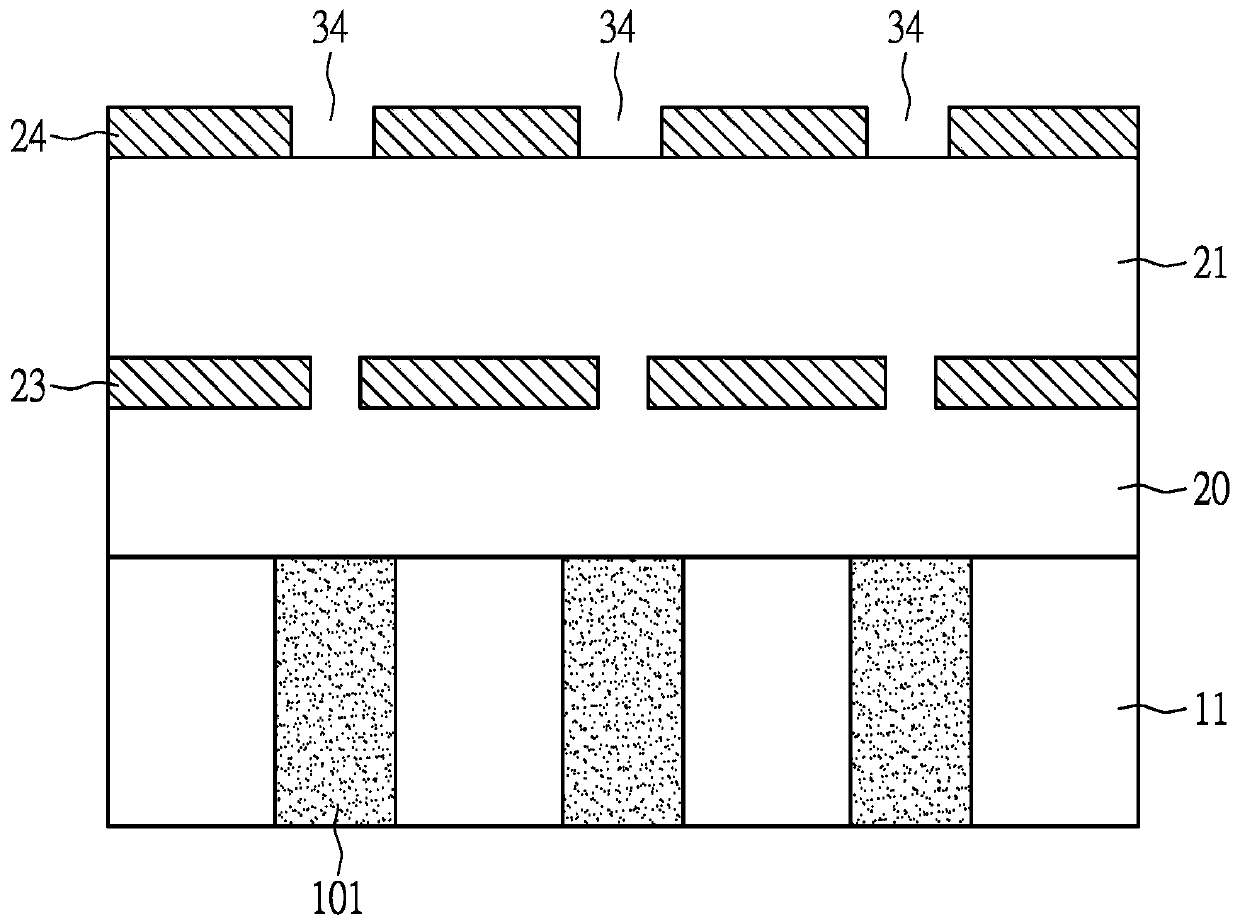

[0035] In order to enable those skilled in the art to fully understand the present invention, detailed steps and structures will be provided in the following description. Obviously, the practice of the invention is not limited to specific details familiar to those skilled in the relevant art. In other instances, well-known structures or steps are not described in detail in order to avoid unnecessarily limiting the invention. The preferred embodiments of the present invention are described in detail below, however, the present invention can be widely implemented in other embodiments besides these detailed descriptions, and the scope of the present invention is not limited, which shall prevail in the appended claims.

[0036] Hereinafter, the embodiments of the present invention will be described in detail with reference to the accompanying drawings. The "embodiment", "this embodiment", "other embodiment" and so on mentioned in the description mean that the specific features, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com