Filter housing and intermediate floor

A filter and housing technology, applied in the field of filter housing, can solve the problems of pump failure, pollution, pipeline blockage, etc., and achieve the effect of simplicity, cost, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

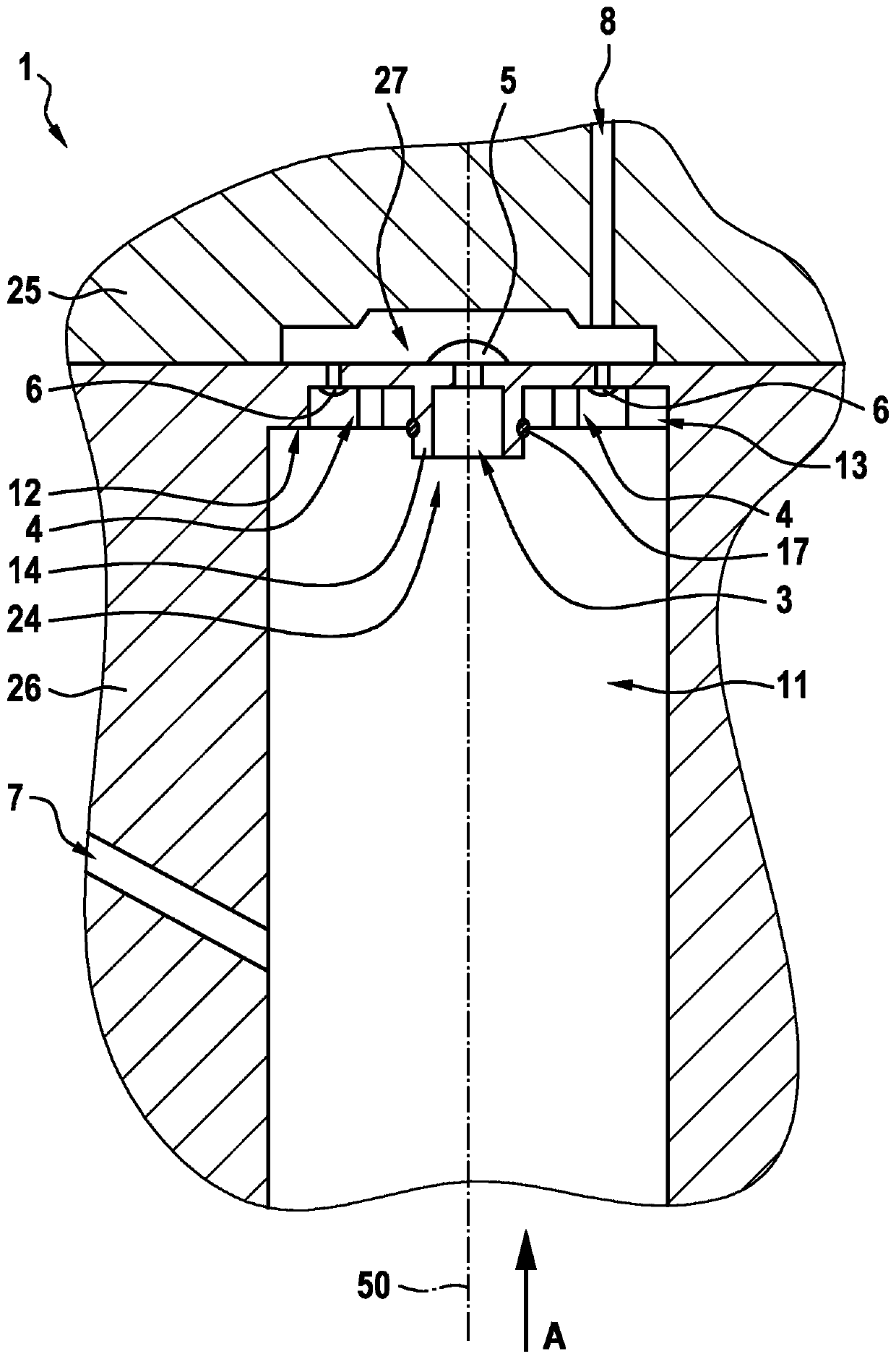

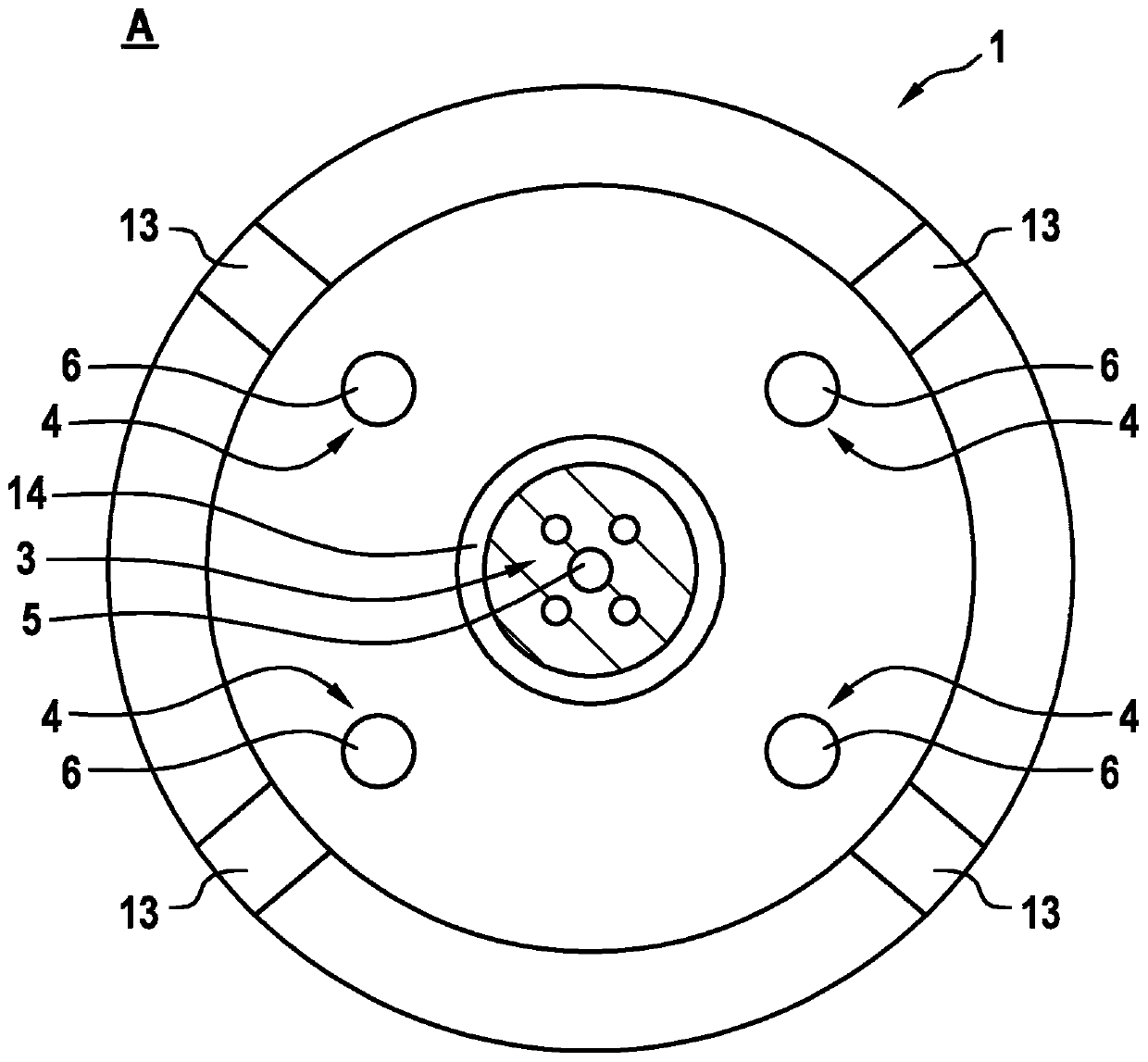

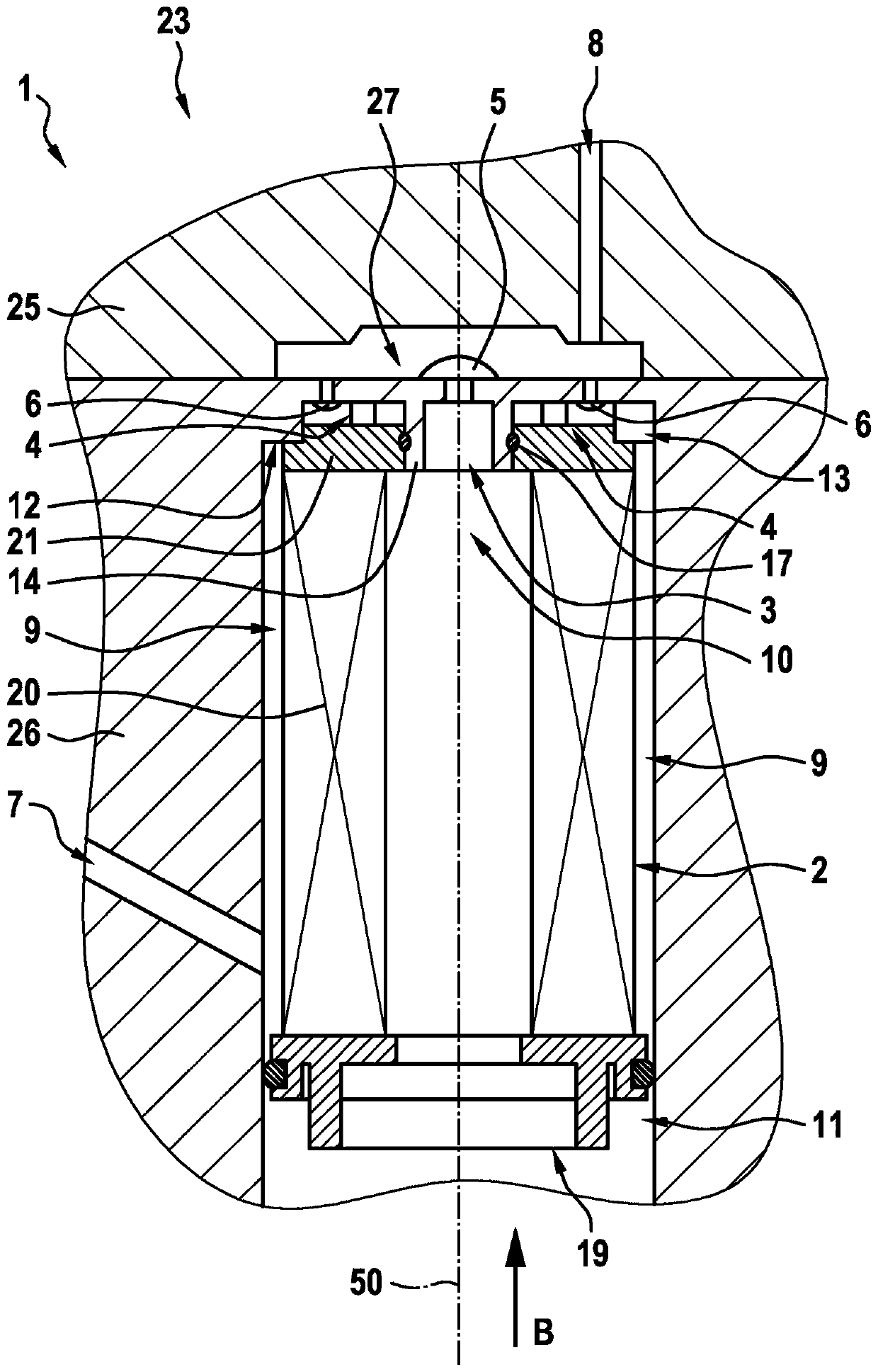

[0030] figure 1 A filter housing 1 according to an exemplary embodiment of the invention is shown schematically. The filter housing 1 comprises in particular an upper housing 25 and a lower housing 26 which can be assembled to form the filter housing 1 . It is provided here that the lower housing 26 has a receptacle 11 into which the filter module 2 can be inserted (see Figures 3 to 7 ). The receptacle 11 is hollow-cylindrical or alternatively conical, wherein the longitudinal axis 50 of the filter housing 1 is the central axis of the hollow-cylindrical shape. The longitudinal axis 50 is the axis of the filter housing 1 along which the filter housing 1 has its greatest extent. If the filter module 2 is to be inserted into the receptacle 11 , this is advantageously done by insertion along the longitudinal axis 50 .

[0031] Several directions are defined by the hollow cylindrical shape of the receptacle 11 of the filter housing 1 . Therefore, the direction specification a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com