Energy-saving air-added brick demolding device for building

A demoulding device and aerated brick technology, which is applied in the field of aerated brick processing, can solve the problems of blanks falling off and sticking together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

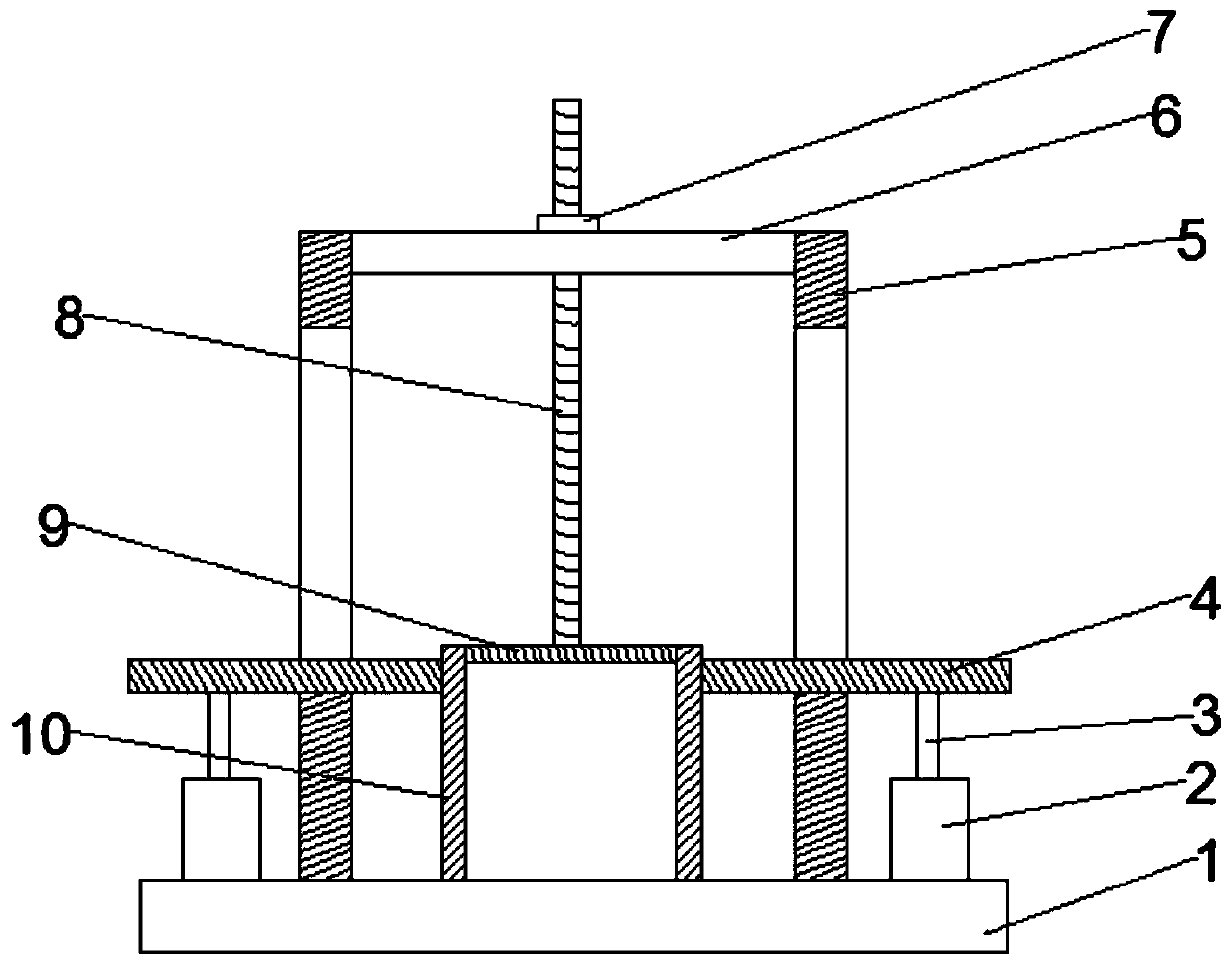

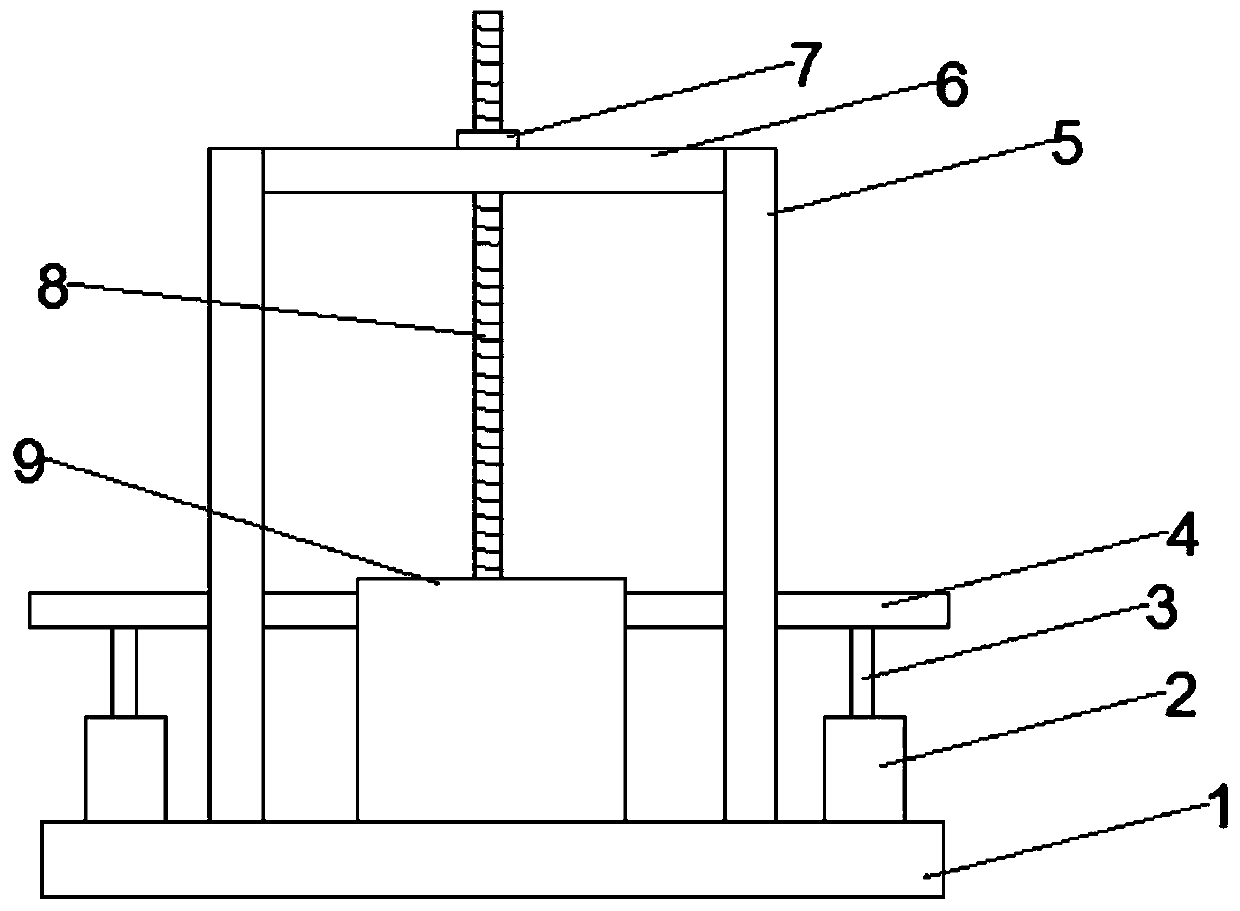

[0016] The reference signs in the accompanying drawings include: bottom plate 1 , cylinder 2 , telescopic rod 3 , connecting rod 4 , riser 5 , support plate 6 , nut 7 , resisting rod 8 , top cover 9 , and frame body 10 .

[0017] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a demoulding device for energy-saving aerated bricks for buildings, including a bottom plate 1, vertically arranged vertical plates 5 are arranged at intervals on the bottom plate 1, and horizontally arranged support plates 6 are fixedly connected between the two vertical plates 5, The support plate 6 is positioned at the top of the two vertical boards 5, the top and the bottom of which are open formwork frame bodies 10 are arranged between the two vertical plates 5, the bottom of the formwork body 10 is in contact with the bottom plate 1, and the two vertical plates 5 There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com