Conveying control method, device and system in store

A conveying control and store technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as poor customer experience, long operation time, and improved operation and distribution efficiency, to avoid excessive number of tracks, Avoid user experience, speed improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

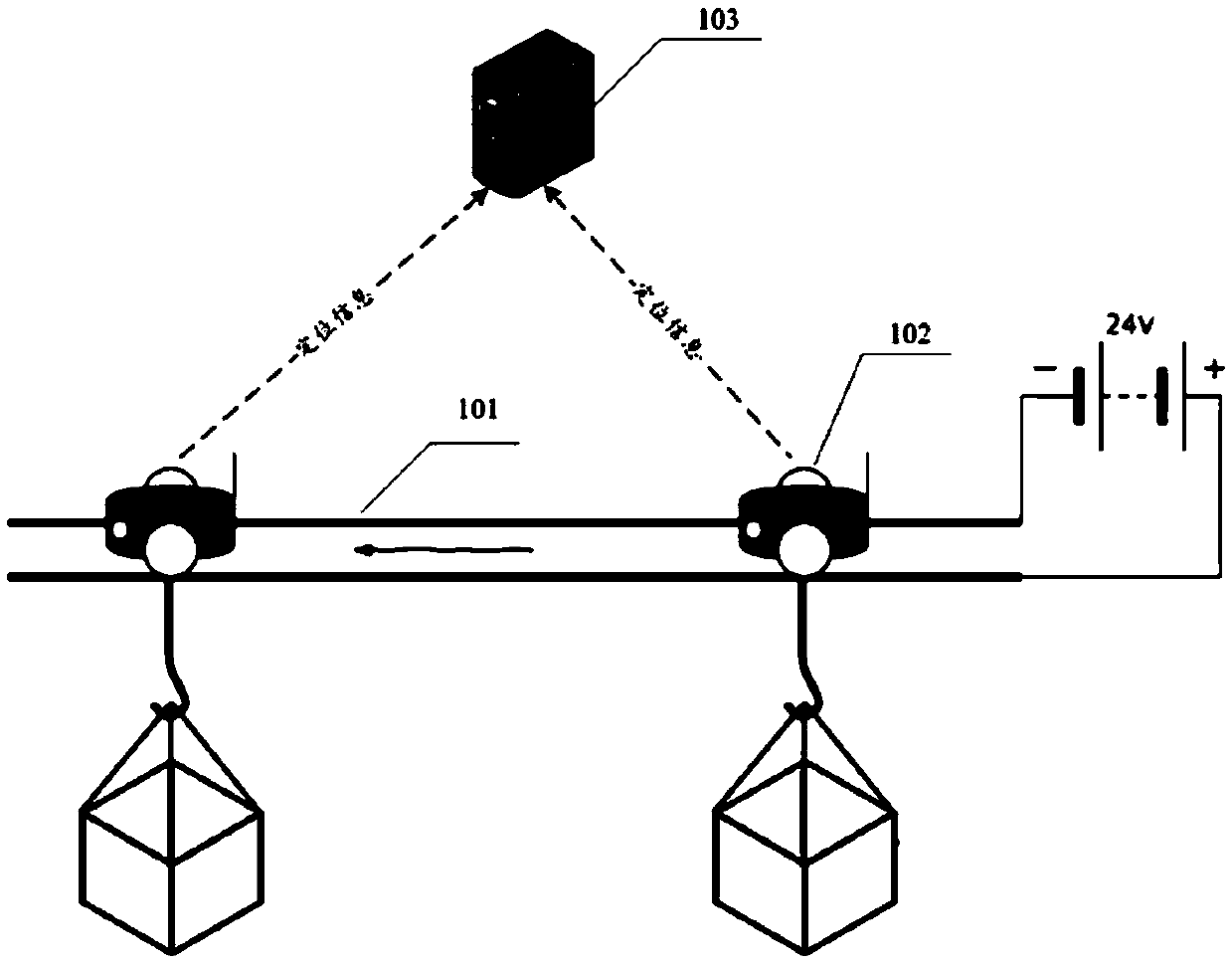

[0049] First of all, the first embodiment provides a transportation control system in the store, see figure 1 , the system can specifically include:

[0050] Overhead track 101, transport vehicle 102 and control server 103;

[0051] The overhead track 101 is used to be arranged in the store from the picking area to the air above the packing area;

[0052] The transport vehicle 102 is used to load the conveying object and run along the overhead track; the conveying object is the picking result obtained by the picking area after executing the target picking task;

[0053] The control server 103 is configured to track and locate the position of the transport vehicle on the overhead track in real time, and control the driving path of the transport vehicle, so as to transport the transport object to the packing area.

[0054] Wherein, the store may specifically refer to a store that sells fresh food, catering and other commodities. For this kind of store, on the one hand, consum...

Embodiment 2

[0091] The second embodiment corresponds to the first embodiment. From the perspective of the control server, a delivery control method in the store is provided. Specifically, the method can be applied to control the automatic delivery system in the store. The automatic conveying system includes an overhead track arranged in the store from the picking area to the sky above the packing area, and a transport vehicle for traveling on the overhead track;

[0092] Specifically, see Figure 5 , the method may specifically include:

[0093] S501: Perform real-time tracking and positioning of the position of the transport vehicle on the overhead track;

[0094] S502: According to the positioning information, control the driving path of the transport vehicle, so that the transport vehicle transports the transport object to the packaging area.

[0095] During the specific implementation, since the transport vehicle is a rail transport vehicle, in order to control the cost of each tran...

Embodiment 3

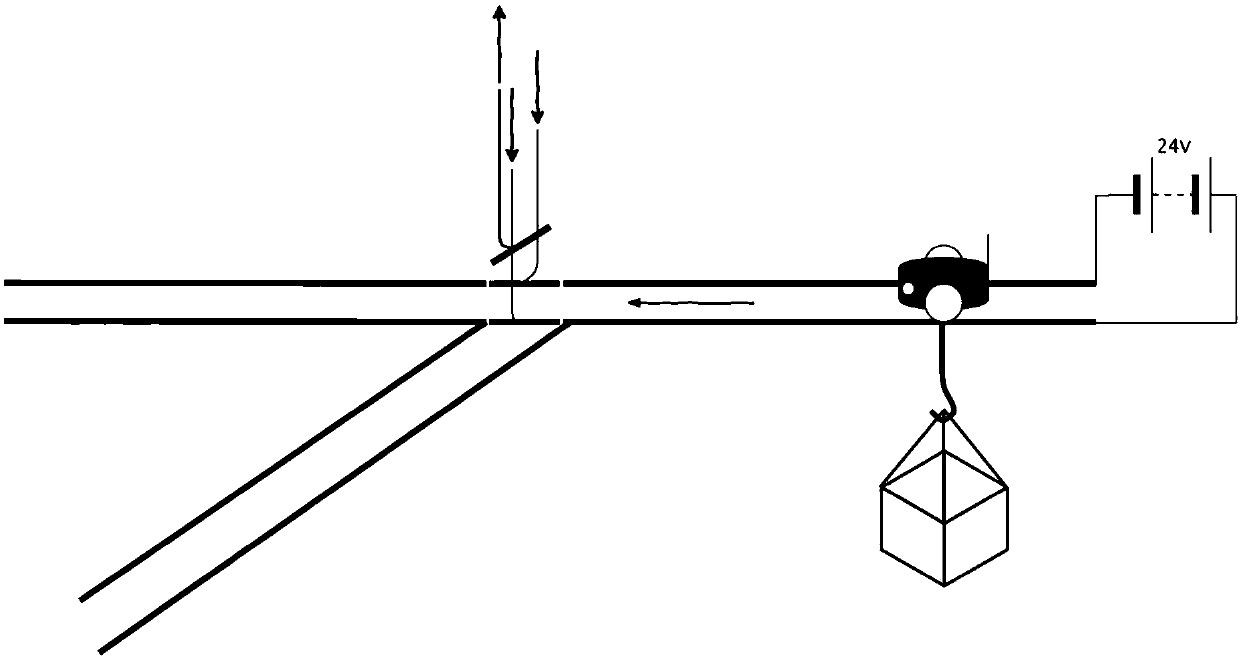

[0100] The third embodiment mainly provides an overhead track system. Specifically, the overhead track is set in the store from the picking area to the air above the packing area, and provides a running track for the transport vehicle, so that the transport vehicle can move along the The overhead track transports the objects to be transported from the picking area to the packing area.

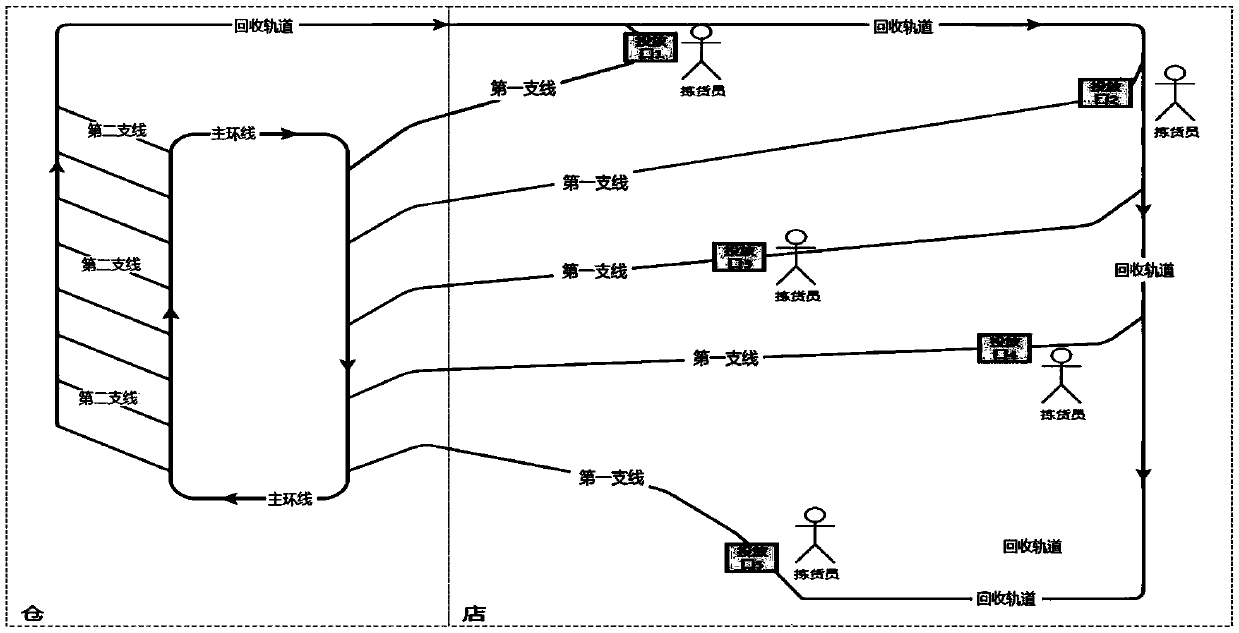

[0101] Specifically, see figure 2 , the picking area in the store includes a plurality of picking areas, and the packing area includes a plurality of packing crossings;

[0102] The overhead track includes a main loop line, a plurality of first branch lines, and a plurality of second branch lines, and the main loop line is provided with a plurality of connection points for respectively connecting with the first branch line and the second branch line; Each first branch line corresponds to each picking area, and the second branch line corresponds to each packing crossing respectively.

[0103]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com