Permeable Gravity Retaining Wall Structure Embedded with Crushed Stone Columns and Its Construction Method

A kind of retaining wall and gravity type technology, applied in the water permeable type gravity type retaining wall structure and its construction field, can solve the problems such as the inability to remove water in time, the inability to release seepage energy, and the easy occurrence of disasters, and achieve obvious social and economic benefits. Benefit, safe and reliable construction method, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

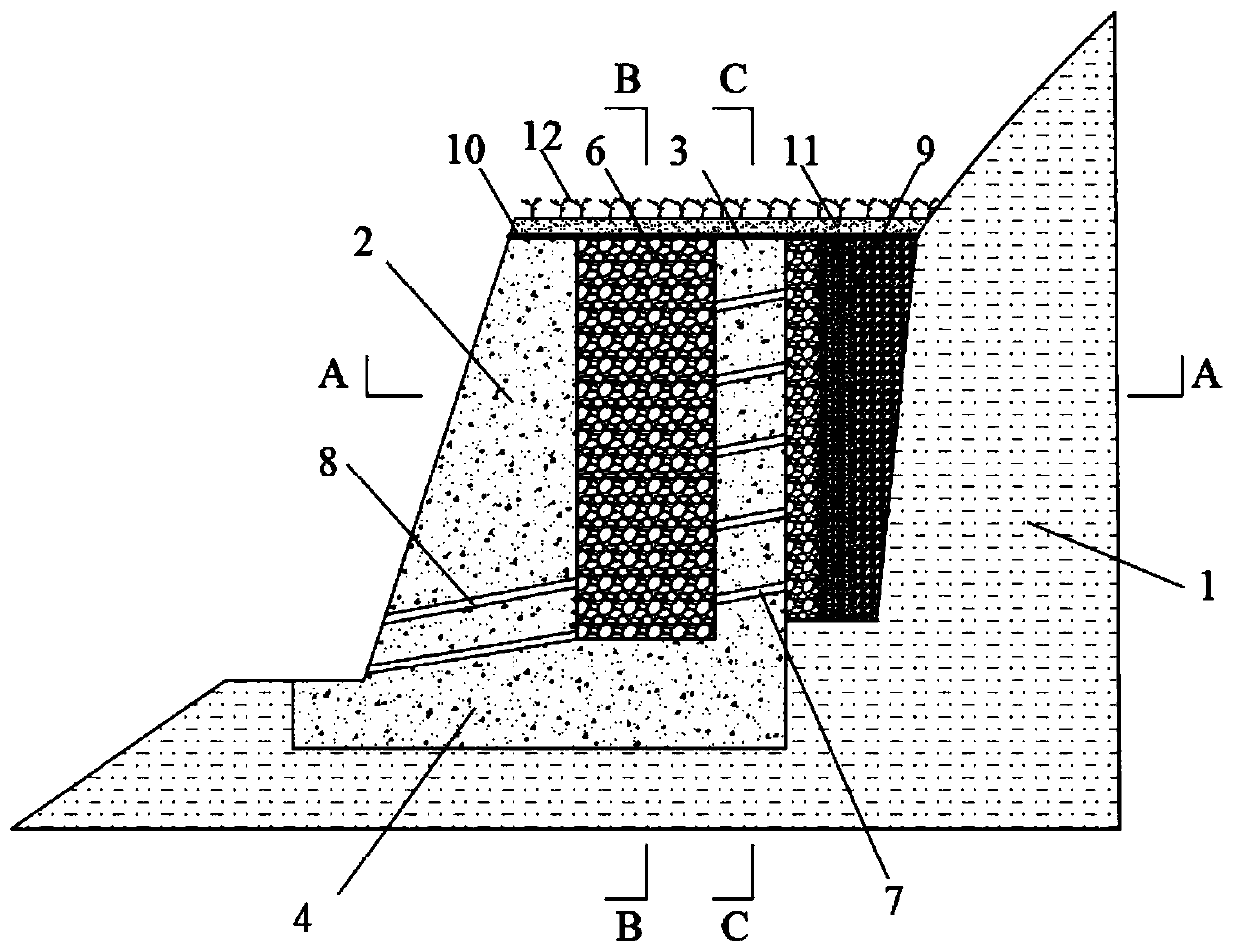

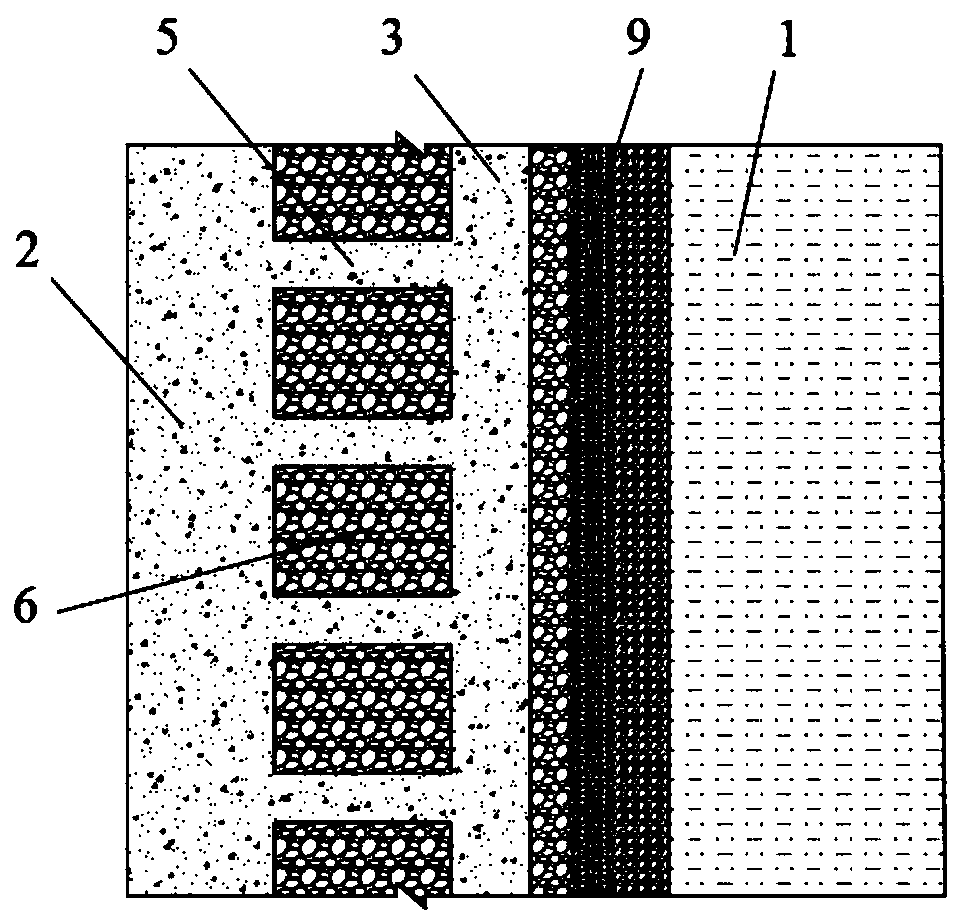

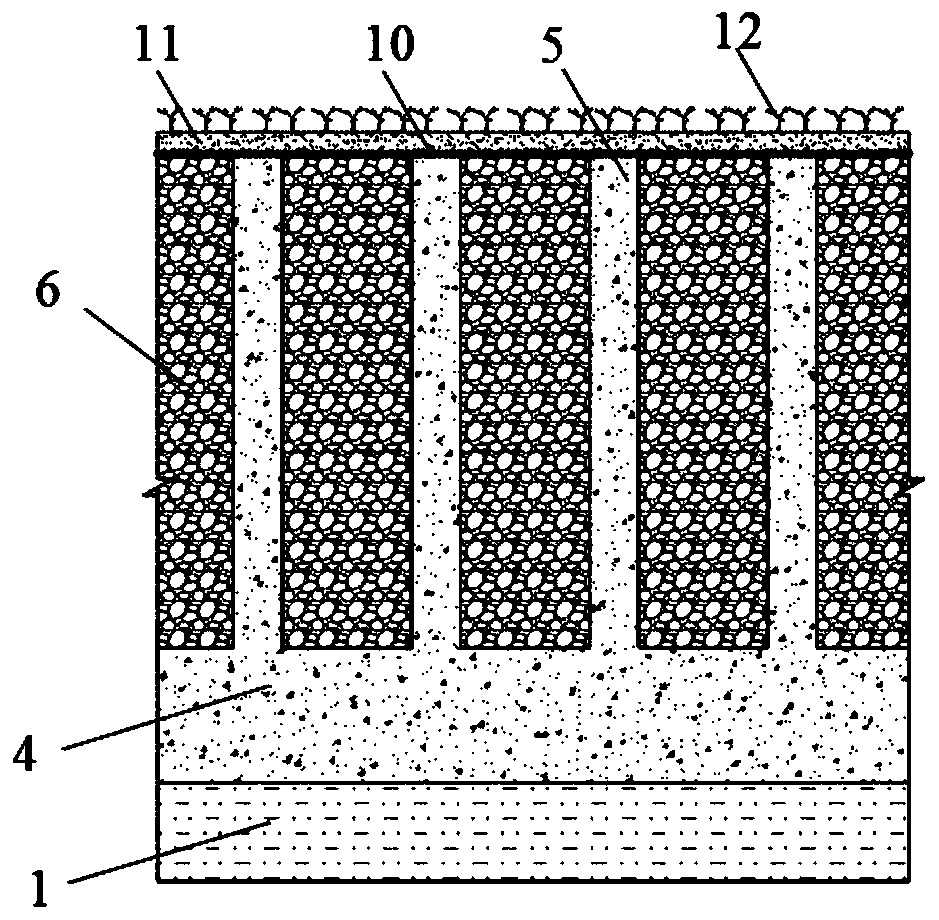

[0033] Such as figure 1 As shown, a permeable gravity retaining wall structure with embedded crushed stone columns includes a concrete wall, wherein the concrete wall is divided into a front wall 2, a rear wall 3, a longitudinal wall 5 and a base 4 The four parts, the front wall 2, the rear wall 3, the longitudinal wall 5 and the base 4 are cast in place as a whole; the front wall 2 and the rear wall are arranged at intervals A plurality of longitudinal walls are connected, and the front and rear walls, and the lower parts of the plurality of longitudinal walls are all fixed on the base 4; the space surrounded by the base, the front and rear walls, and the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com