Crankshaft components for internal combustion engines

A technology for internal combustion engines and crankshafts, used in crankshafts, bearing components, crankshaft bearings, etc., can solve the problems of weakening bearing capacity, affecting the blocking effect, and being unable to withstand damage, and achieving the effect of improving the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

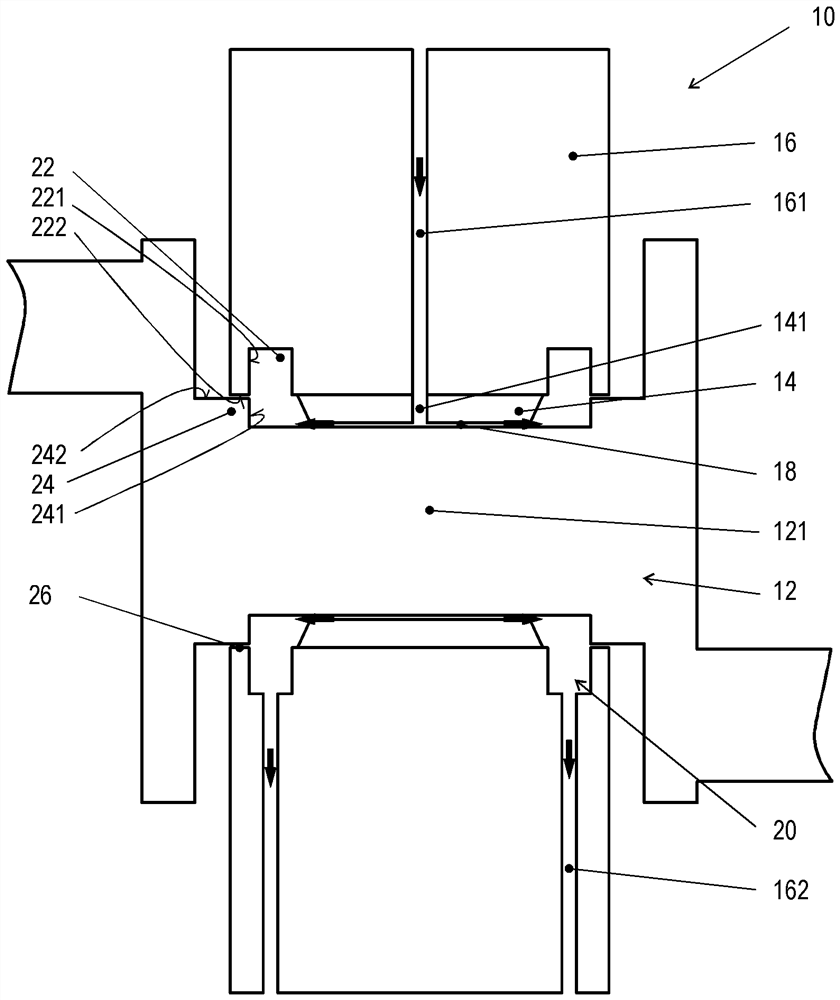

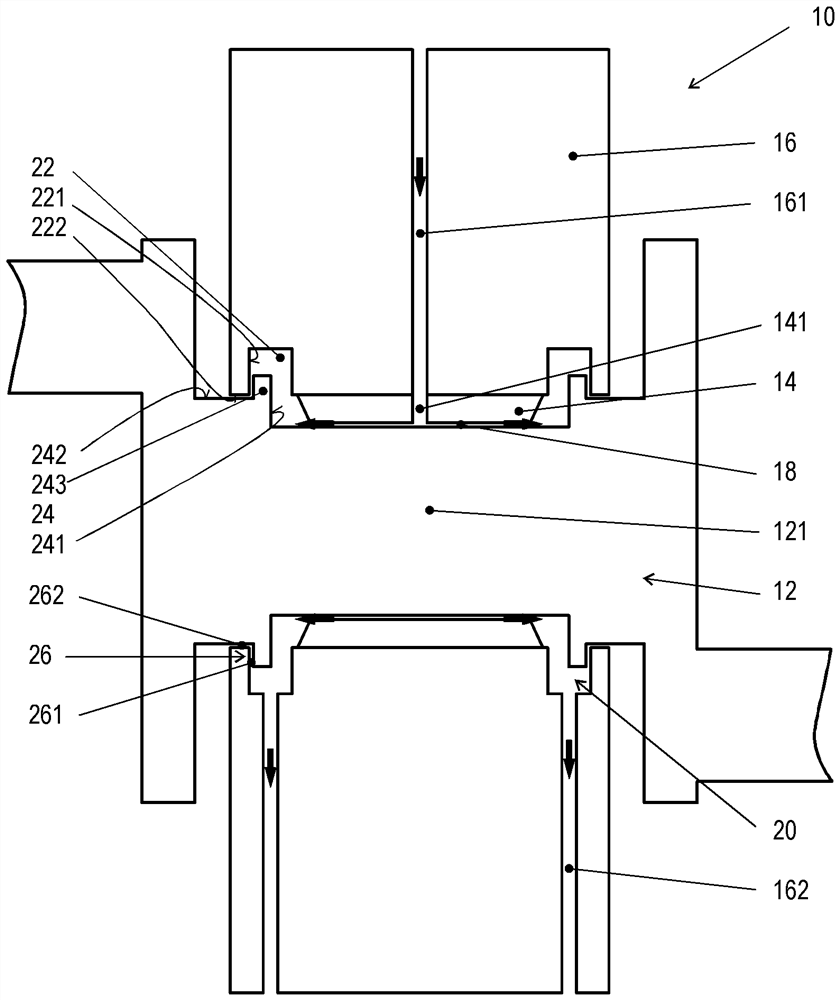

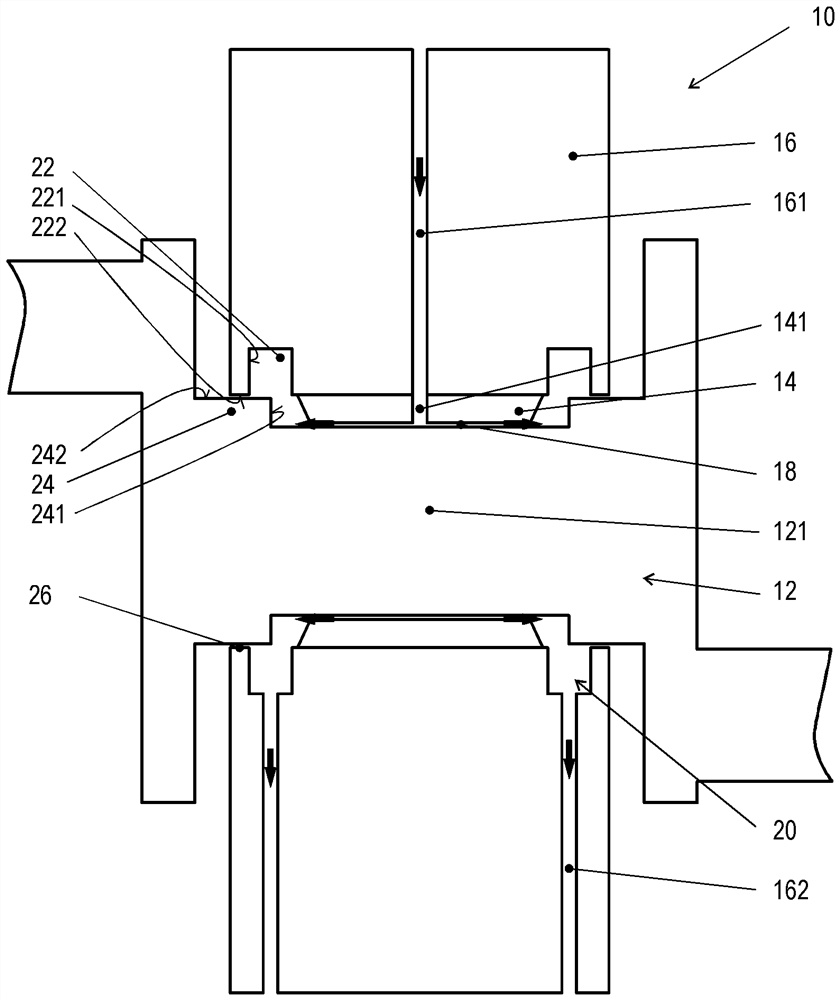

[0045] Figures 1 to 3A section through the crankshaft assembly 10 according to the invention is shown in each case and should, if possible, be discussed together first. In the following, reference is made to the individual drawings with regard to the specifics of the embodiments.

[0046] The crankshaft 12 is slidingly mounted in the region of its main journal 121 in a bearing receptacle 16 , which is fastened to the internal combustion engine housing, not shown in greater detail. This sliding bearing is realized by means of a bearing shell 14 , which is fixed on the bearing support 16 and forms a bearing gap 18 relative to the main journal 121 .

[0047] The bearing carrier 16 carries an oil feed channel 161 , which terminates in the through-bore 141 of the bearing shell 14 . Along this path, oil can be pressed from an oil reservoir (not shown) under pressure into the bearing gap 18 and in this way form the sliding film required for a low-friction bearing. In this case, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com