Axial Force Monitoring Device and Experimental Method of Full-length Bonded Inclined Bolt

A monitoring device and bolt technology, which can be used in measuring devices, force/torque/work measuring instruments, force sensors in holes of stressed structures, etc., can solve problems such as difficulty in detecting bolts in tunnel construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

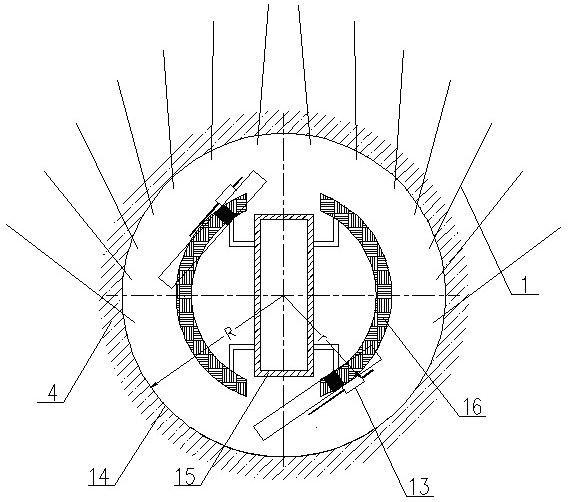

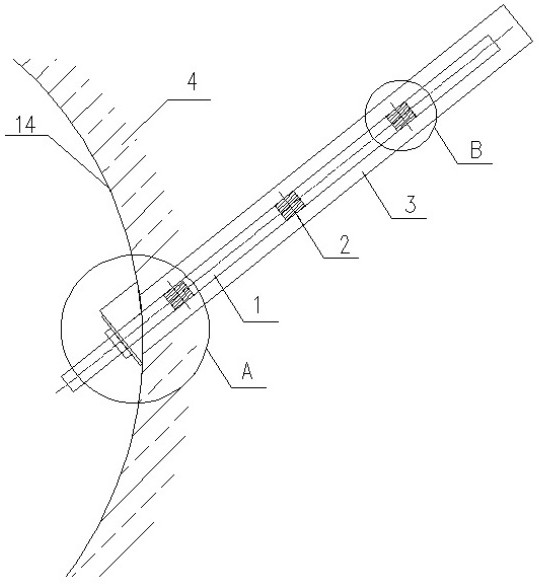

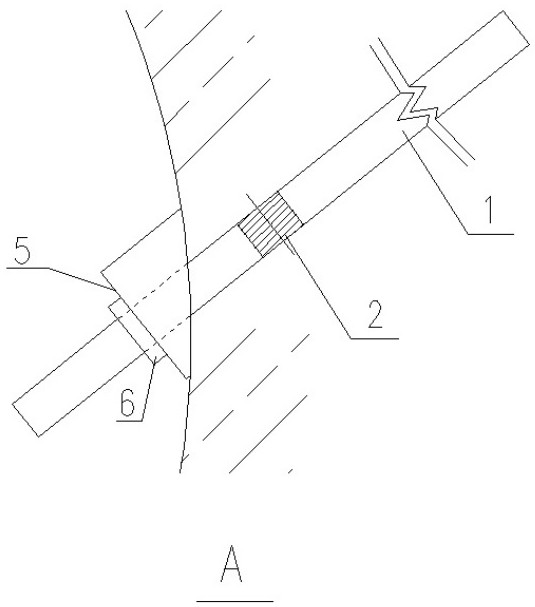

[0037] A full-length bonded inclined bolt axial force monitoring device, see Figure 1 to Figure 10 , including the assembled anchor to be tested, the dynamometer is installed on the assembled anchor to be tested, and a special-shaped protective sleeve is set on the outside, and the bottom end of the assembled anchor to be tested is installed to fix it in the tunnel The inclined backing plate on the rock; the assembled anchor rod to be tested includes at least 3 sections of threaded steel bars, the two ends of the threaded steel bars are provided with threads, and a dynamometer is installed between every two threaded steel bars via thread fit; the special-shaped The protective sleeve is a hollow cylindrical casing, and the end surfaces on both sides are respectively provided with at least two symmetrical sets of externally inclined trumpet-shaped baffles; the inclined pad is provided with holes for anchor rods and wires.

[0038] The length of the threaded steel bar in the ass...

Embodiment 2

[0056] The principle of this embodiment is the same as that of Embodiment 1, except that the dynamometer is a spindle-shaped sensor of revolution, and both ends are hollow cylinders with internal threads. The two ends are thick for stress, and the middle is thin for cooperation with other components and the realization of related measurements, especially the width of the special-shaped sleeve is less than 2 / 3 of the length of the rotary body, and the self-locking between the equipment is realized through the friction of the arc surface, so that Ensure the stability of the equipment during the grouting process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com