Micro-fluidic-channel miniature assembly type biosensor structure

A biosensor and micro-assembly technology, which is applied in the field of biochemical parameter collection, can solve the problems of manufacturing technology and structural principles that limit the development of biosensors, high manufacturing difficulty, and complicated technology, and achieve convenient fine operation, compact structure, and fluid flow. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

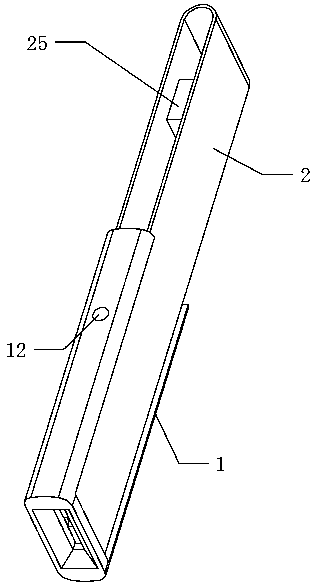

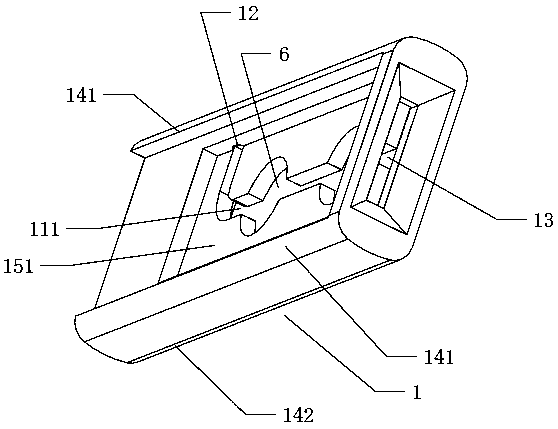

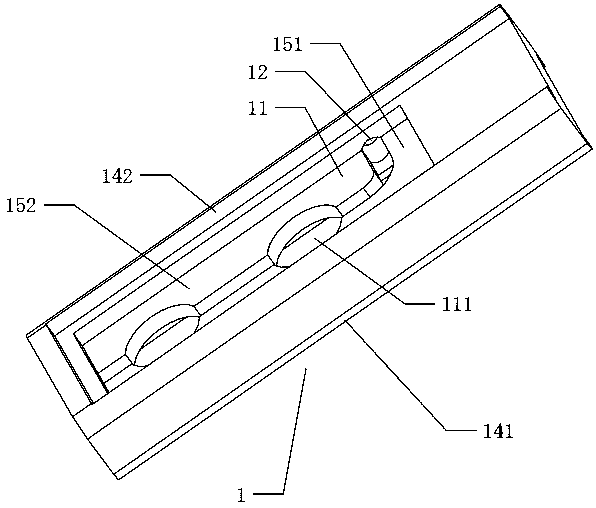

[0051] A micro-channel micro-assembled biosensor structure, including a bracket 1 and a flexible circuit board 2, the flexible circuit board 2 is provided with a working electrode 21 and a counter electrode 22;

[0052] The bracket 1 includes a middle support 11, the middle support 11 is provided with a micro-channel 111, and the micro-channel 111 runs through the height direction of the middle support 11;

[0053] The flexible circuit board 2 is bent and set, and the working electrode 21 and the counter electrode 22 are respectively located on two opposite surfaces inside the bent flexible circuit board 2. into the microchannel 111; the top surfaces of the working electrode 21 and the counter electrode 22 are oppositely arranged.

[0054] In this embodiment, the side of the bracket 1 is provided with a liquid discharge hole 12, the front of the bracket 1 is provided with a liquid inlet hole 13, and the liquid inlet hole 13 is provided with a drainage and filtering structure. ...

Embodiment 2

[0064] A micro-channel micro-assembled biosensor structure, including a bracket 1 and a flexible circuit board 2, the flexible circuit board 2 is provided with a working electrode 21 and a counter electrode 22;

[0065] The bracket 1 includes a middle support 11, the middle support 11 is provided with a micro-channel 111, and the micro-channel 111 runs through the height direction of the middle support 11;

[0066] The flexible circuit board 2 is bent and set, and the working electrode 21 and the counter electrode 22 are respectively located on two opposite surfaces inside the bent flexible circuit board 2. into the microchannel 111; the top surfaces of the working electrode 21 and the counter electrode 22 are oppositely arranged.

[0067] In this embodiment, the flexible circuit board 2 is provided with a working electrode extension platform 23 and a counter electrode extension platform 24; the working electrode 21 extends from the working electrode extension platform 23, and...

Embodiment 3

[0083] A micro-channel micro-assembled biosensor structure, including a bracket 1 and a flexible circuit board 2, the flexible circuit board 2 is provided with a working electrode 21 and a counter electrode 22;

[0084] The bracket 1 includes a middle support 11, the middle support 11 is provided with a micro-channel 111, and the micro-channel 111 runs through the height direction of the middle support 11;

[0085] The flexible circuit board 2 is bent and set, and the working electrode 21 and the counter electrode 22 are respectively located on two opposite surfaces inside the bent flexible circuit board 2. into the microchannel 111; the working electrode 21 and the counter electrode 22 overlap in the height direction; the sides of the working electrode 21 and the counter electrode 22 are oppositely arranged.

[0086] In this embodiment, the flexible circuit board 2 is provided with a working electrode extension platform 23 and a counter electrode extension platform 24; the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com