Electric spindle thermal characteristic analysis method based on heat generation-heat dissipation power

A technology of heat dissipation power and heat generation power, which is applied in the field of CNC machine tools, and can solve problems such as different heat dissipation capabilities and inaccurate analysis of cooling liquid heat dissipation power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

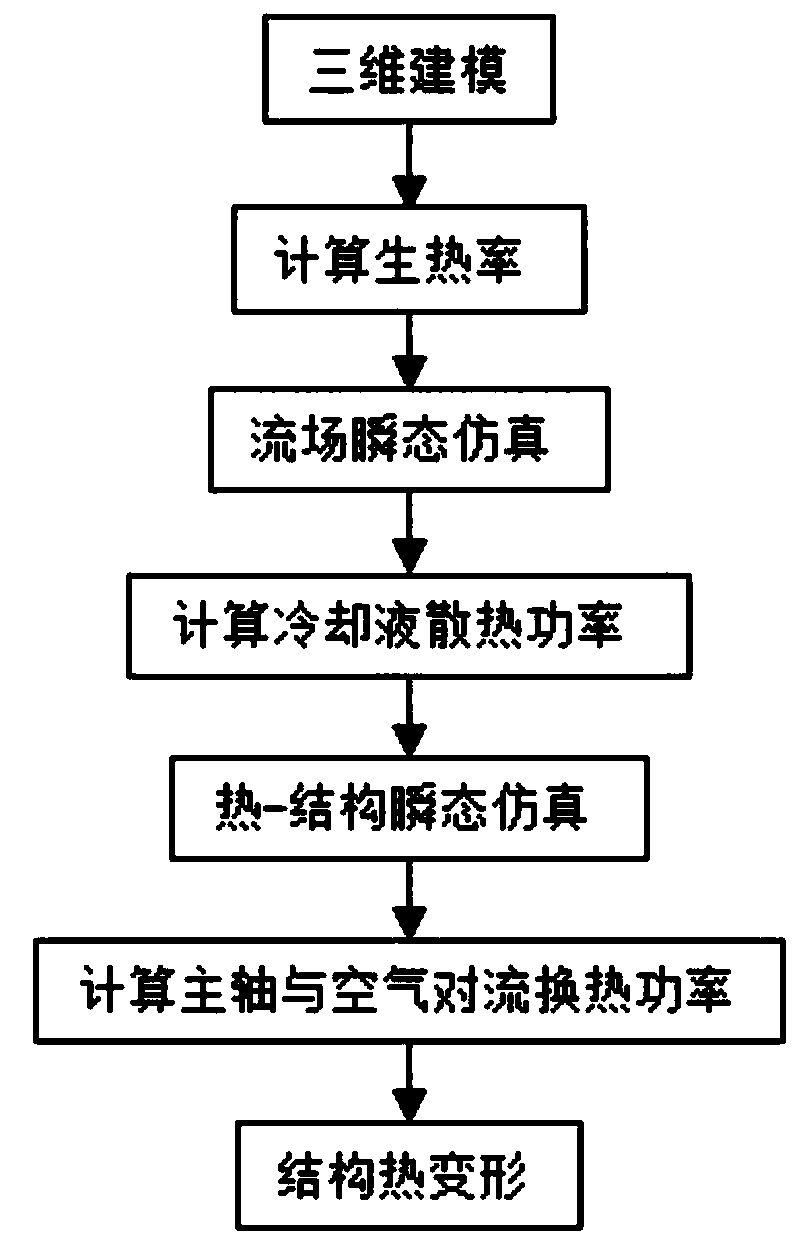

[0020] An analysis method for the thermal characteristics of the electric spindle based on heat generation and heat dissipation power. Through the combination of finite element simulation and empirical formula, the heat generation power and heat dissipation power of the electric spindle are comprehensively calculated, and the thermal characteristics of the electric spindle are analyzed. The finite element simulation software is Ansys Company of the United States. Ansys 17.2, using the Fluent, Transient Thermal and TransientStructural modules, the analysis process is as follows figure 1 shown;

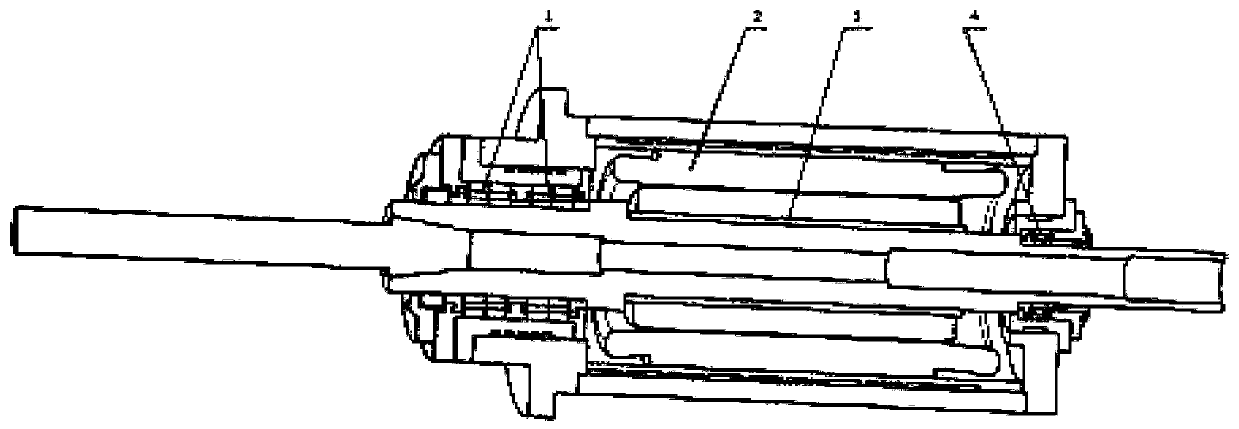

[0021] Step 1, establish the three-dimensional models of the solid region and the fluid region of the electric spindle, respectively as follows figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com