Test system and test method for simulating working condition of brake booster feedback disc

A technology of brake booster and testing method, which is applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., and can solve the problem of different static states of deformation, unspecified test tools and test tool layout schemes, artificial Large experimental errors in readings and other issues, to achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

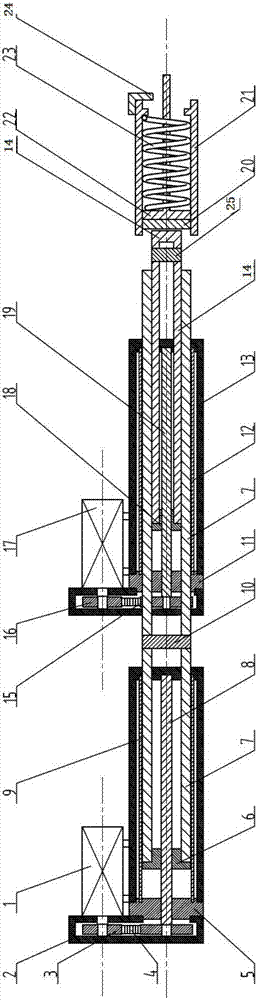

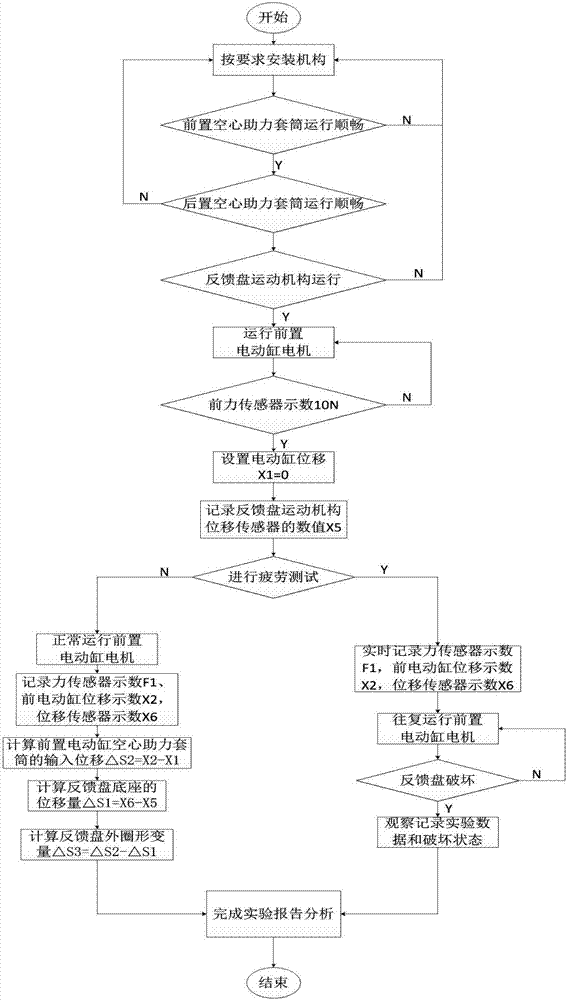

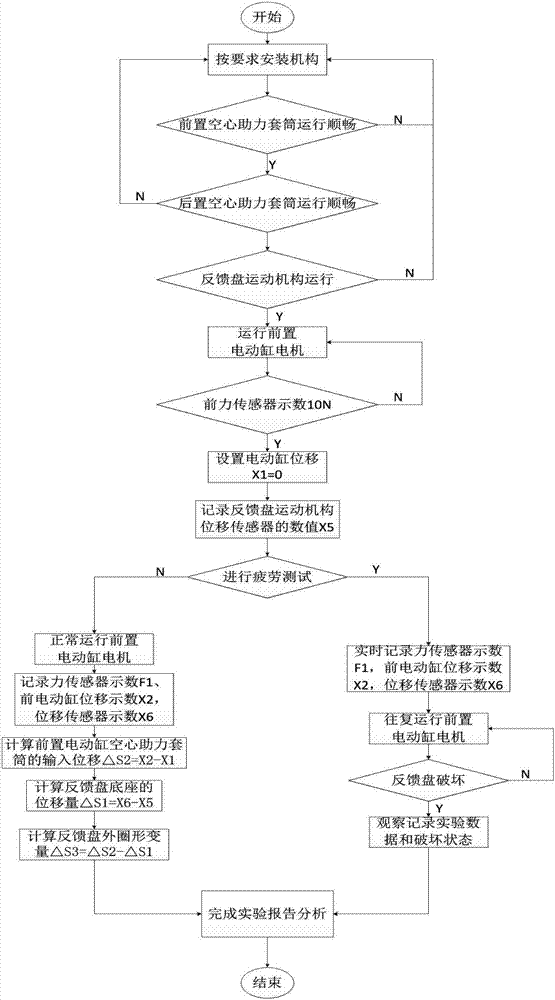

[0052] The embodiment of the present invention provides a simulated brake booster feedback disc operating condition test system. After the front and rear electric cylinders and the feedback disc movement mechanism are correctly installed, the connection of the electric cylinder is checked to ensure its smooth and reliable operation. At the same time, the feedback disc movement mechanism The overall central axis should be horizontally coincident with the axes of the front electric cylinder booster sleeve (7) and the rear electric cylinder booster sleeve (14), so as to ensure that the front and rear electric cylinder booster s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com