Automatic shoe sole gluing method and system based on three-dimensional reconstruction and storage medium

A 3D reconstruction and gluing technology, which is applied in image data processing, 3D modeling, instruments, etc., can solve problems such as small application range, large curvature change of surface, and complex surface, so as to reduce manual workload and wide application range , Improve the effect of glue coating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

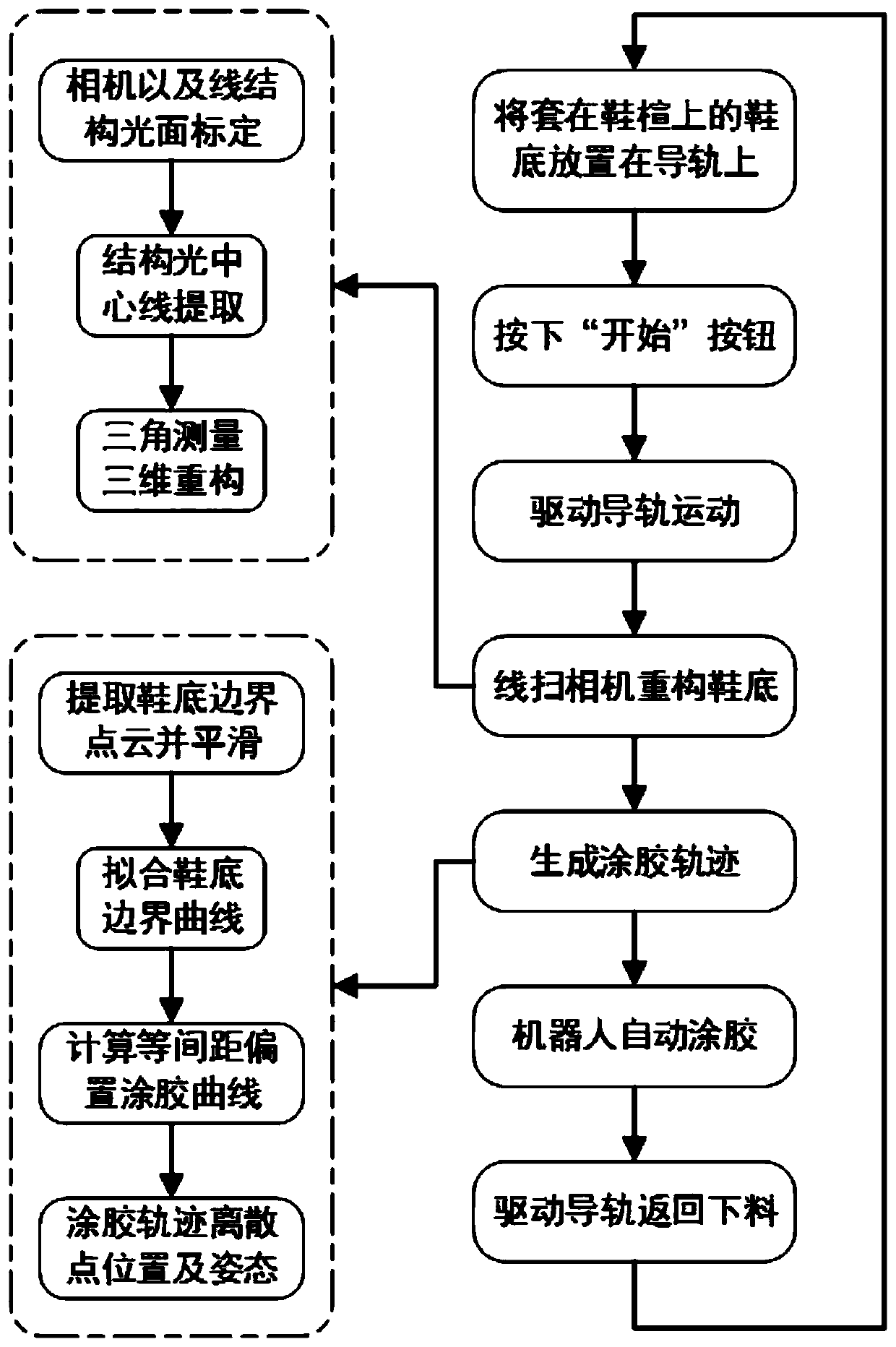

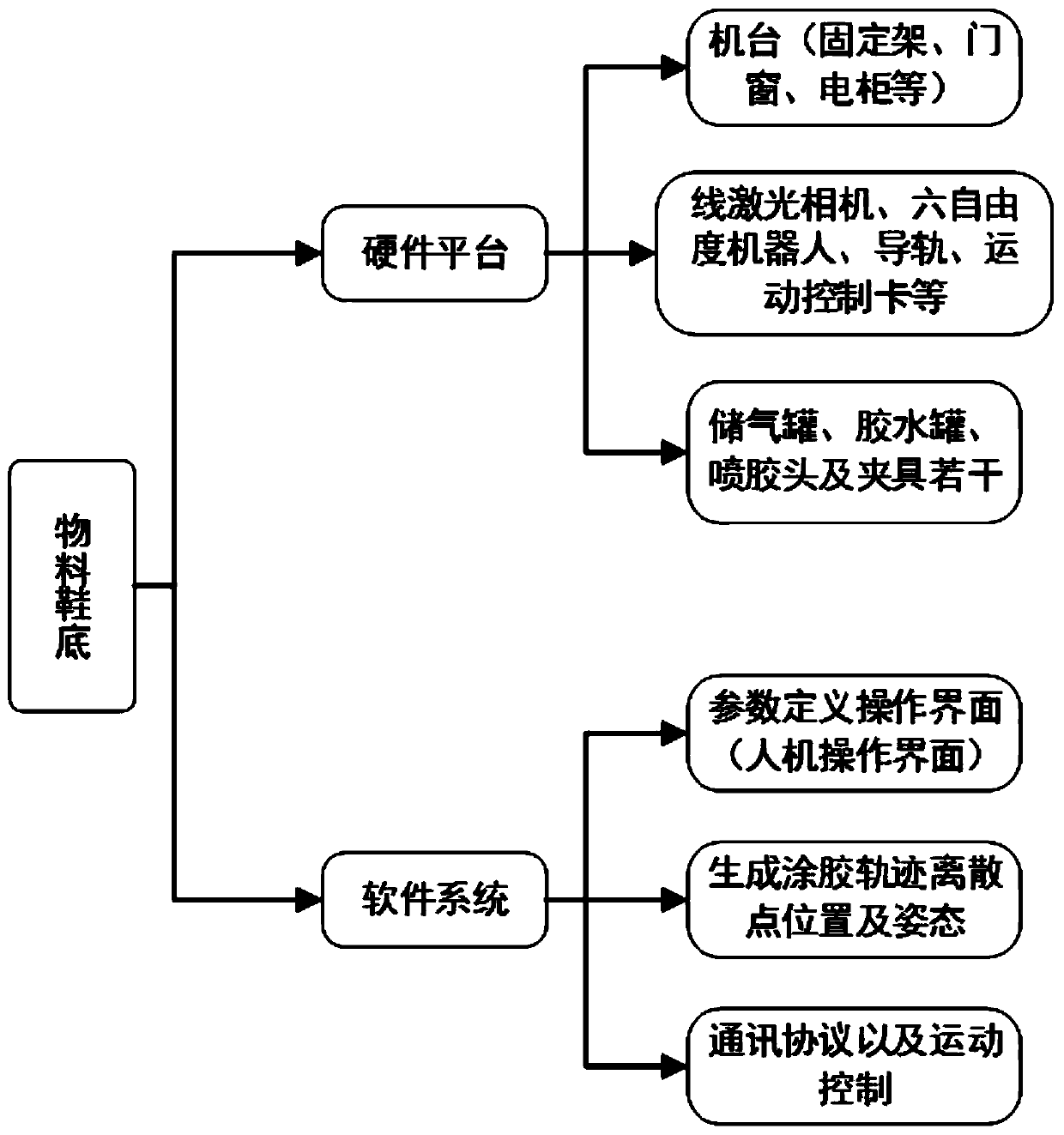

[0056] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description. For the step numbers in the embodiment of the present invention, it is only set for the convenience of explanation and description, and there is no limitation on the order of the steps. The execution order of each step in the embodiment can be carried out according to the understanding of those skilled in the art Adaptive adjustment.

[0057] In order to solve the problem that the automatic gluing technology in the prior art cannot be applied to women's shoes, the present invention proposes an automatic gluing method, system and storage medium for shoe soles based on three-dimensional reconstruction.

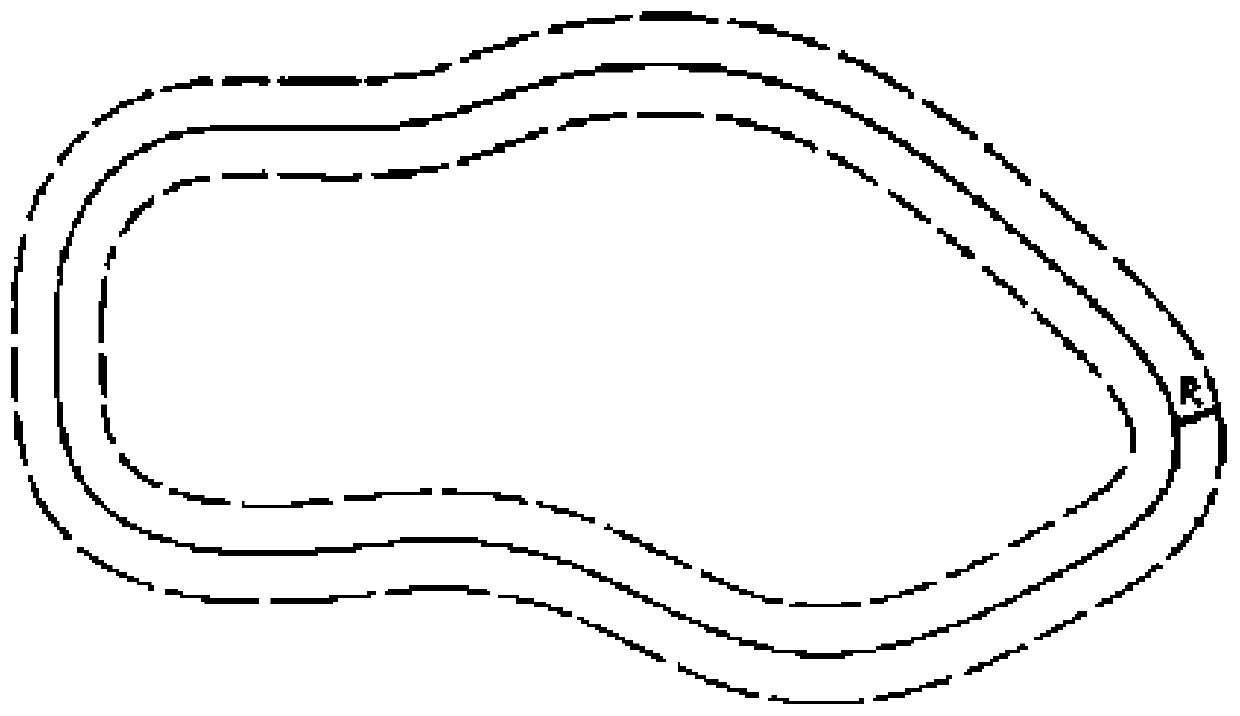

[0058] Describe in detail the specific implementation steps of a kind of sole automatic gluing method based on three-dimensional reconstruction. In the present embodiment, the sole to be glued is a high-heeled women...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap