Control method for keeping constant temperature of glue solution

A control method and constant temperature controller technology, applied to the surface coating liquid device, coating, etc., can solve the problems of large heat dissipation noise, low heat dissipation flow rate, waste of compressed air, etc., to achieve the improvement of glue output stability, Avoid voltage shock and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

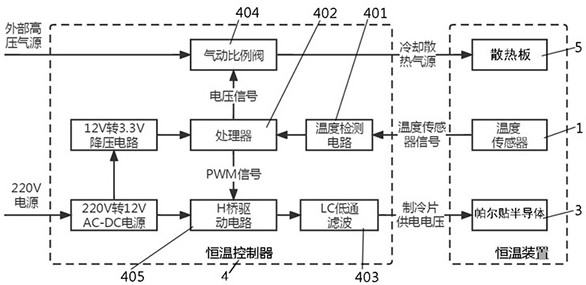

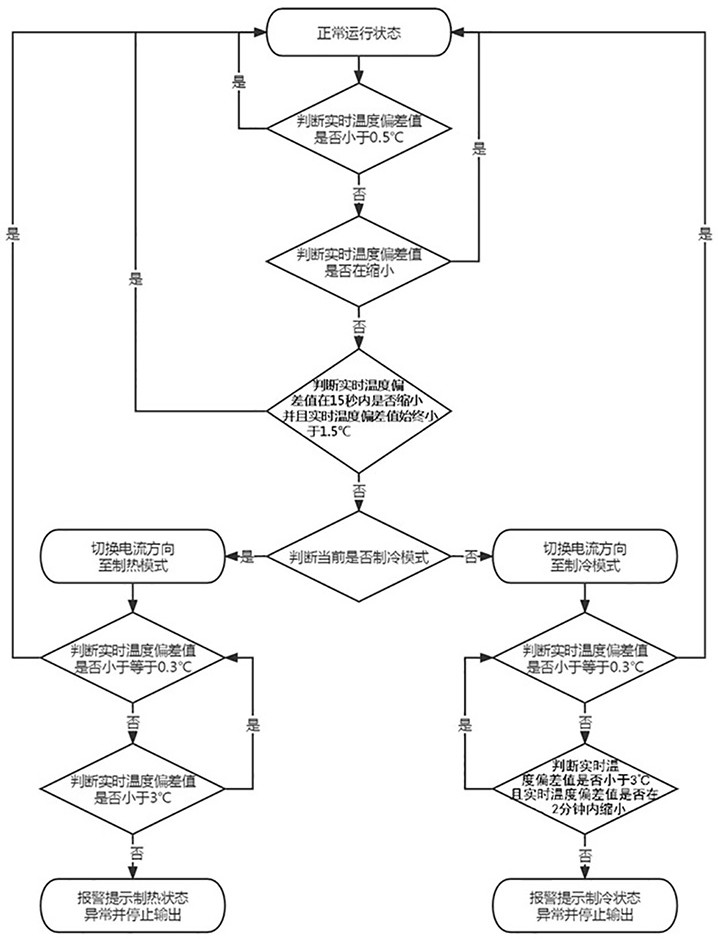

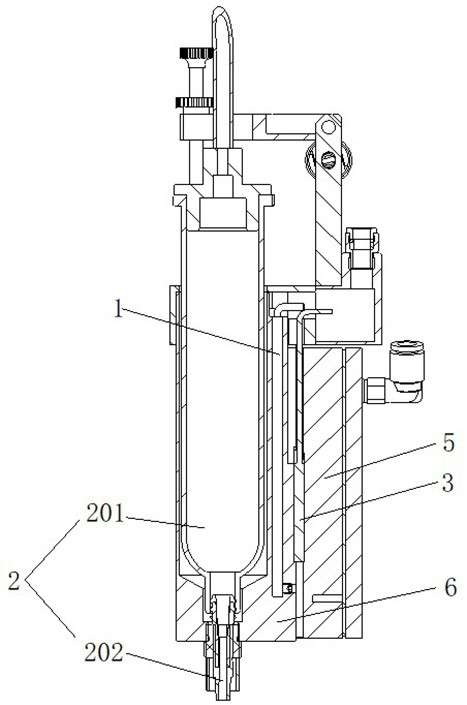

[0034] See figure 1 , figure 2 and image 3 , a control method of the present invention for maintaining a constant temperature of glue liquid, the valve seat in the constant temperature device is controlled by the constant temperature controller 4 to maintain a constant temperature, and the constant temperature device includes a temperature sensor 1, a glue dispenser 2, a Peltier semiconductor 3, a heat sink 5 And the valve seat 6 , the temperature sensor 1 , the glue dispenser 2 and the Peltier semiconductor 3 are all mounted on the valve seat 6 , wherein the glue dispenser 2 includes a first glue barrel 201 and a first nozzle 202 . The thermostatic controller 4 includes a temperature detection circuit 401 , a processor 402 , an LC low-pass filter 403 , a pneumatic proportional valve 404 and an H-bridge drive circuit 405 .

[0035] Specifically, an accommodating cavity is defined in the barrel of the valve seat 6 , and the glue dispenser 2 can be installed in the accommoda...

Embodiment 2

[0092] See figure 1 , figure 2 and Figure 4 , for ease of understanding Figure 4 Structure, Figure 4 The middle valve seat 6 and the glue dispenser 2 are in a separated state. Compared with the first embodiment, the difference between the second embodiment and the second embodiment is that the glue dispenser 2 includes the second glue. The barrel 203 , the second nozzle 204 , the flow channel 205 and the piezoelectric valve body 206 , the second rubber barrel 203 and the piezoelectric valve valve body 206 are installed above the flow channel 205 , and the second nozzle 204 is located on the piezoelectric valve valve body 206 Just below the temperature sensor 1 is embedded in the embedded groove of the valve seat 6 . During assembly, the flow channel 205 needs to be assembled into the valve seat 6 , and the second nozzle 204 is matched with the assembly hole on the valve seat 6 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap