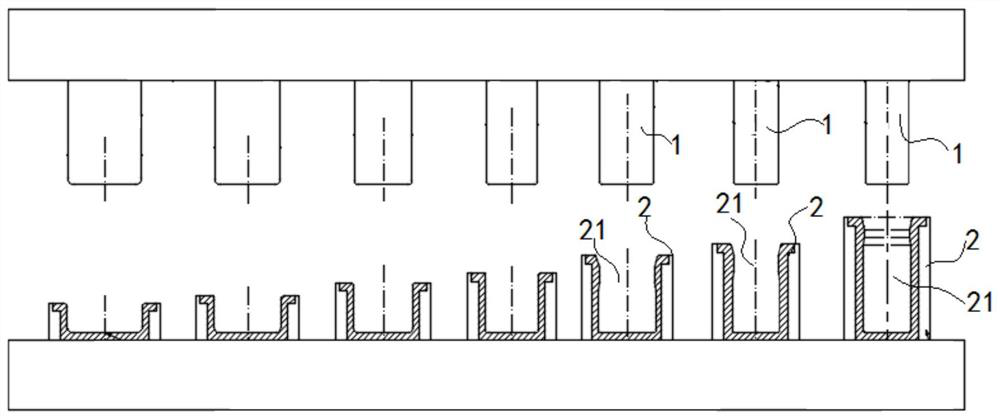

A High Thinning Ratio Deep Drawing Process for Deep Tube Parts

A technology of thinning rate and deep cylinder, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as pulling cracks, breaking, deformation, etc., to reduce wire drawing, uniform wall thickness, and reduce deep drawing steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

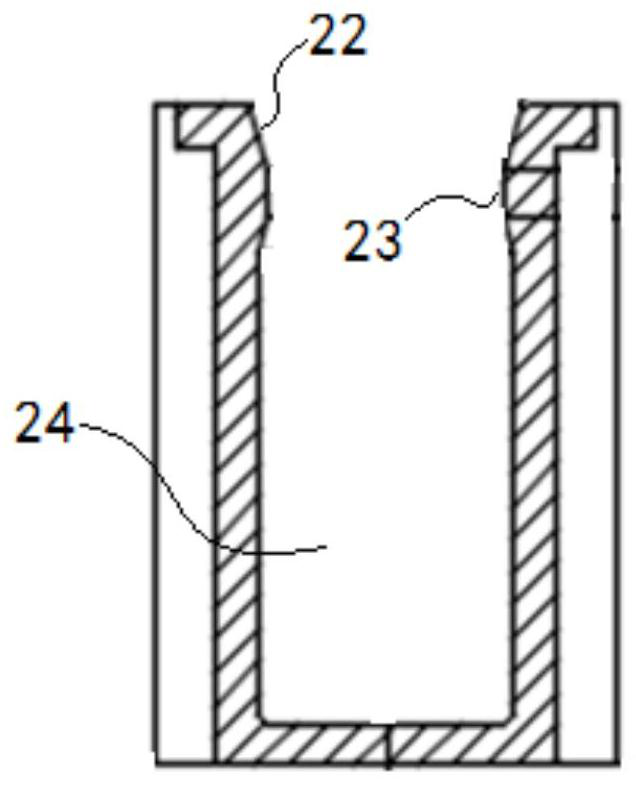

[0058] The drawing process of this embodiment is divided into 7 steps. Before drawing, the drawing depth of each pass is allocated according to the size of the original blank and the size of the set finished deep tube and the die gap is adjusted, and then the relevant drawing is performed. Under the conditions of parameters (blankholder force, friction coefficient, deep drawing speed), the circular blank with a diameter of 75mm and a thickness of 0.5mm is thinned to a cylindrical piece with a thickness of 0.25mm.

[0059] 1. Preliminary formation

[0060] Deep drawing step 1: After placing the blank on the die, press the blank with a blank holder. The blank holder force can be 5000N-20000N, and this embodiment is 8000N. Next, lubricating fluid is added to control the coefficient of friction between the blank and the mold, and finally the punch is controlled to press down to draw the blank.

[0061] In this step, the friction coefficient between the blank and the punch is 0.1,...

Embodiment 2

[0091] The drawing process of this embodiment is divided into 6 steps. Before drawing, the drawing depth of each pass is allocated according to the size of the original blank and the set size of the finished deep tube, and the die gap is adjusted, and then the relevant drawing is performed. Under the conditions of parameters (blankholder force, friction coefficient, deep drawing speed), the circular blank with a diameter of 62mm and a thickness of 0.4mm is thinned to a deep tube with a diameter of 21mm and a thickness of 0.2mm.

[0092] 1. Preliminary formation

[0093] Deep drawing step 1: After placing the blank on the die, press the blank with a blank holder. The blank holder force can be 5000N-20000N, and 6500N is used in this embodiment. Next, lubricating fluid is added to control the coefficient of friction between the blank and the mold, and finally the punch is controlled to press down to draw the blank.

[0094] In this step, the coefficient of friction between the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com