Splicing type prefabricated composite floor slab forming mold and splicing method thereof

A technology of laminating floor slabs and forming molds, applied in the direction of molds, etc., to achieve the effects of reducing production costs, not easily deformed, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0031] In this embodiment, the size of the prefabricated laminated slab is: length*width*height=3220mm*2600mm*60mm, the distance between the longitudinal ribs is 200mm, and the distance between the transverse ribs is 200mm.

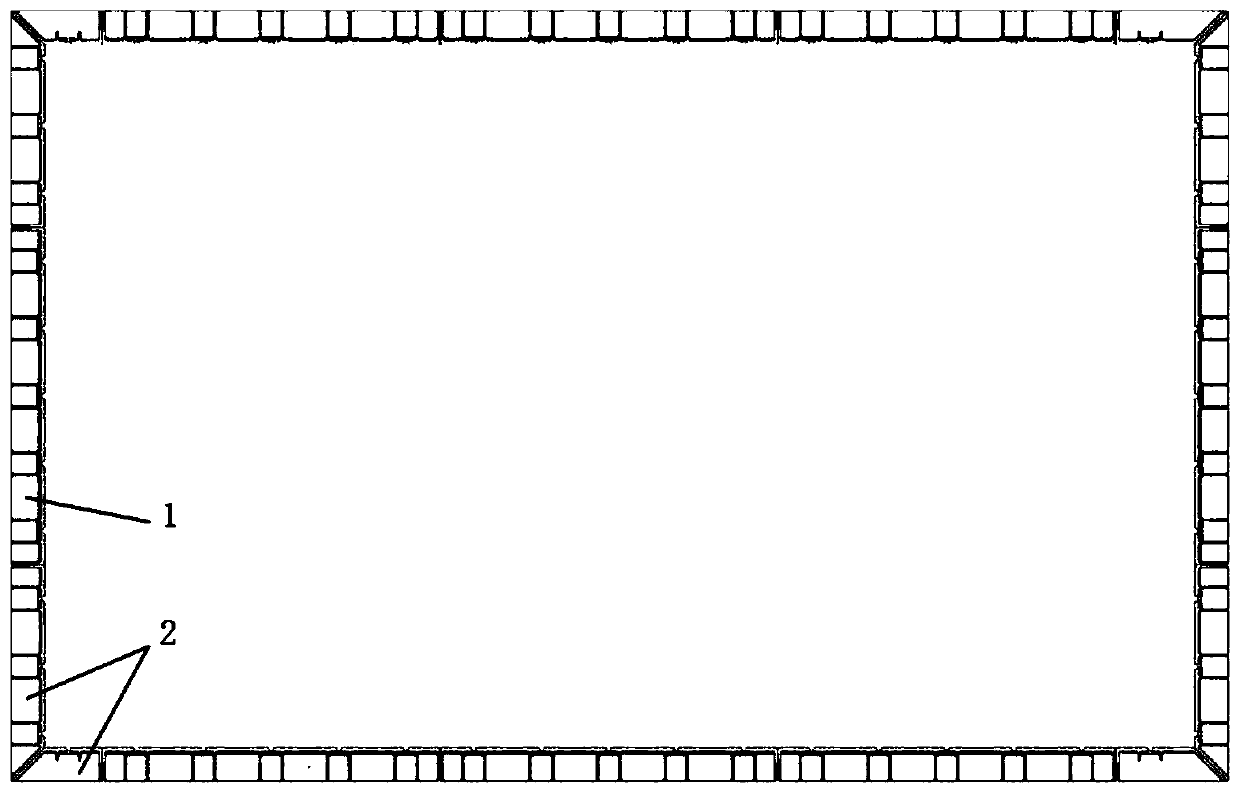

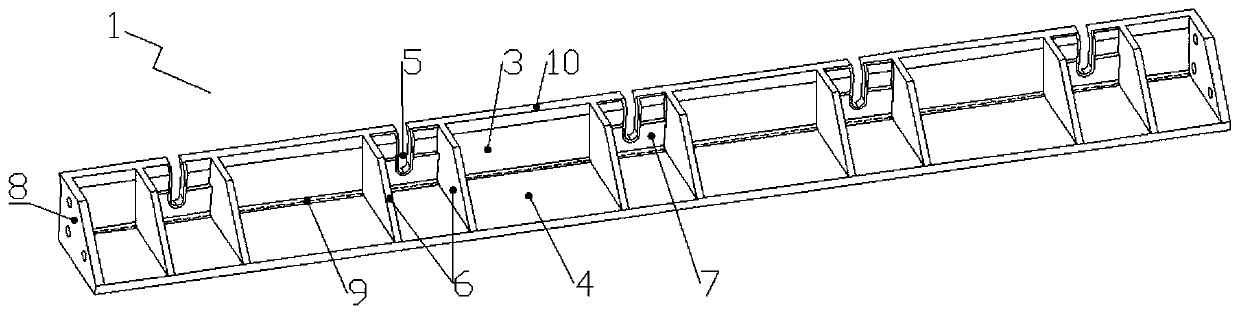

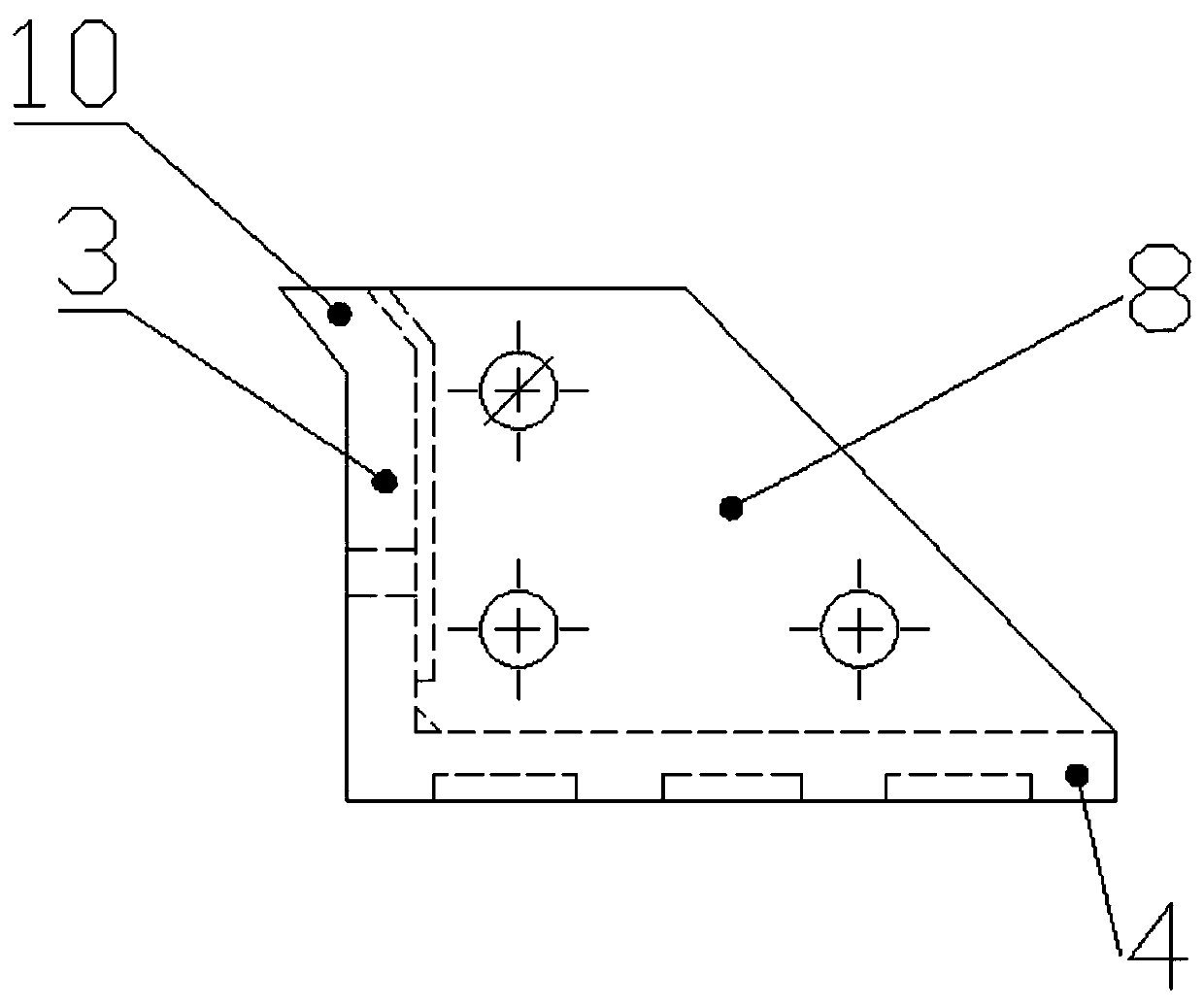

[0032] A mould for splicing prefabricated laminated floor slabs, which includes a general connection mold 1 and a corner connection mold 2, wherein:

[0033] According to the design shape and size of the prefabricated laminated floor slab, the general connection molds 1 described in several sections are sequentially connected along the straight line direction to form the long side mold and the wide side mold respectively, and both ends of the long side mold and the wide side mold are set The corner connection mold 2, the long side mold and the wide side mold are connected through the corner connection mold 2 to form a rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com