A needle cylinder seat of a single-sided circular weft machine with interchangeable needle cylinders of different diameters

A technology of needle cylinder seat and circular weft machine, which is applied in knitting, weft knitting, textile and paper making, etc., can solve the problems of low utilization rate of equipment, no extension space, complicated installation and debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

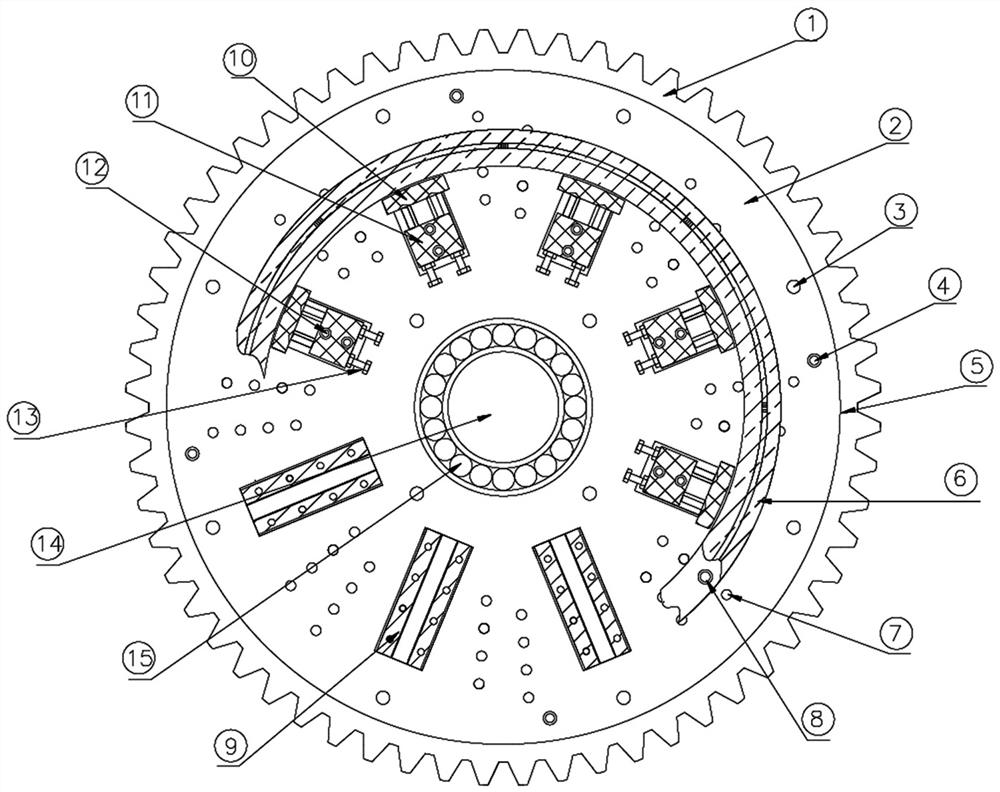

[0030] The present invention proposes a needle cylinder seat of a single-sided circular weft machine with interchangeable needle cylinders of different diameters, which can connect and control the needle cylinders without the steps of the cylinder seat. 6-8 needle cylinders with adjacent diameters can be installed on the same needle cylinder body, and multiple adjustment seat slots and matching adjustment devices are used to control the radial adjustment of the needle cylinder; it is easy to disassemble and install the needle cylinder, Debug features with high precision, such as figure 1 As shown, the following setting method is adopted in particular: including a large toothed plate 1, a syringe seat body 2 is arranged on the large toothed plate 1, an adjustment seat groove 9 and a syringe 6 are arranged on the syringe seat body 2, and the adjustment An adjusting device for radially positioning the syringe 6 is also provided on the seat groove 9 .

[0031]As a preferred setti...

Embodiment 2

[0033] This embodiment is further optimized on the basis of the foregoing embodiments, and the same parts as the foregoing technical solutions will not be repeated here, such as figure 1 As shown, further in order to better realize the present invention, the following arrangement structure is adopted in particular: the adjustment device includes an adjustment seat 11 and a cushion block 10, the adjustment seat 11 is arranged on the adjustment seat groove 9 through a set bolt 12, and the pad The block 10 is arranged between the adjustment seat 11 and the inner wall of the syringe 6 .

[0034] As a preferred setting scheme, the adjustment device arranged on the adjustment seat groove 9 is mainly composed of an adjustment seat 11 and a cushion block 10. The adjustment seat groove 9 is preferably provided with more than one row of holes in the length direction. On the adjustment seat groove 9 An adjustment seat 11 is provided through a set bolt 12, and the set bolt 12 limits the a...

Embodiment 3

[0036] This embodiment is further optimized on the basis of any of the above-mentioned embodiments, and the same parts as the aforementioned technical solutions will not be repeated here, such as figure 1 As shown, further in order to better realize the present invention, the following setting structure is adopted in particular: the adjustment seat 11 is also provided with a jacking bolt 13 for attaching the spacer 10 to the inner wall of the syringe 6, and the adjustment seat 11 11. Holes are provided in the horizontal and vertical directions of the large toothed plate 1. The vertical holes are used to set the set bolts 12, and the horizontal holes are used to set the jacking bolts 13. When setting, The contact surface between the spacer 10 and the inner wall of the syringe 6 is a matching structure, the spacer 10 is arranged between the adjustment seat 11 and the inner wall of the syringe 6, and the spacer 10 is pressed against the inner wall of the syringe 6 by using the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com