Steel structure support structure

A support structure and steel structure technology, applied in the field of steel structure support, can solve problems such as delay in construction period, slow construction speed, and weak support, and achieve the effect of improving stability and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

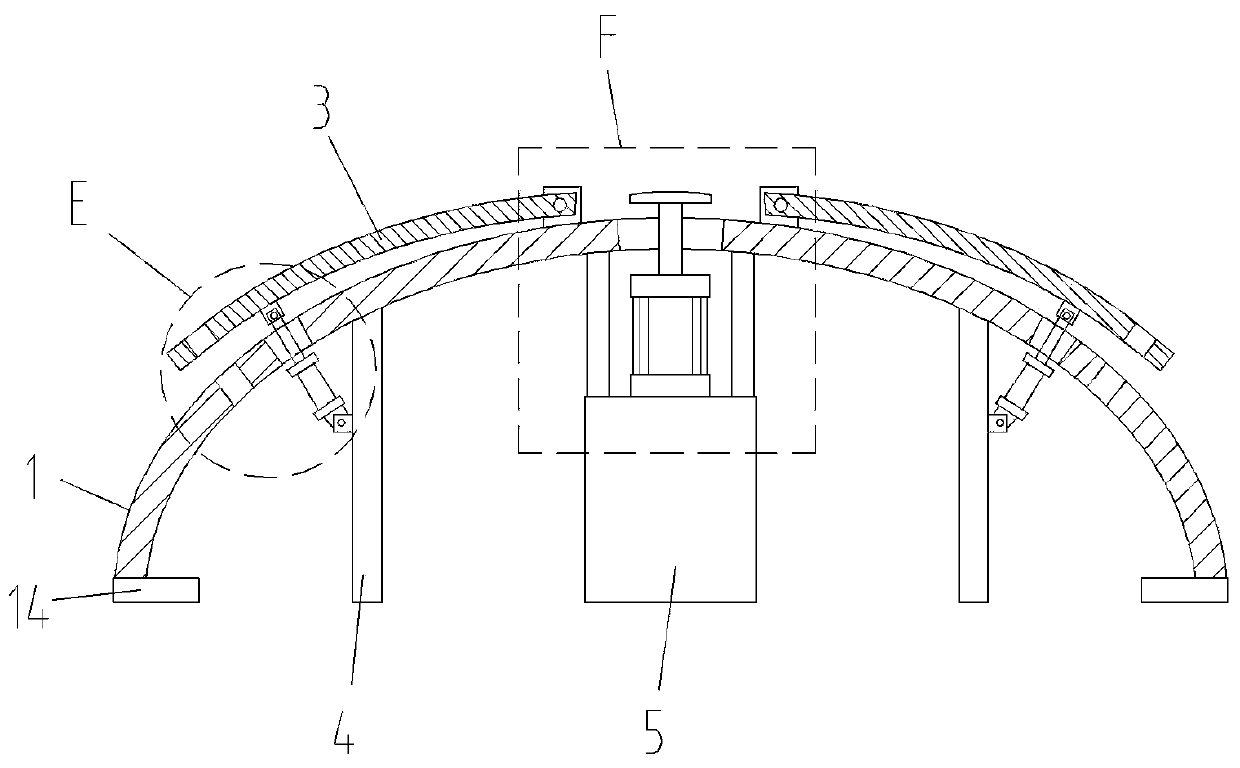

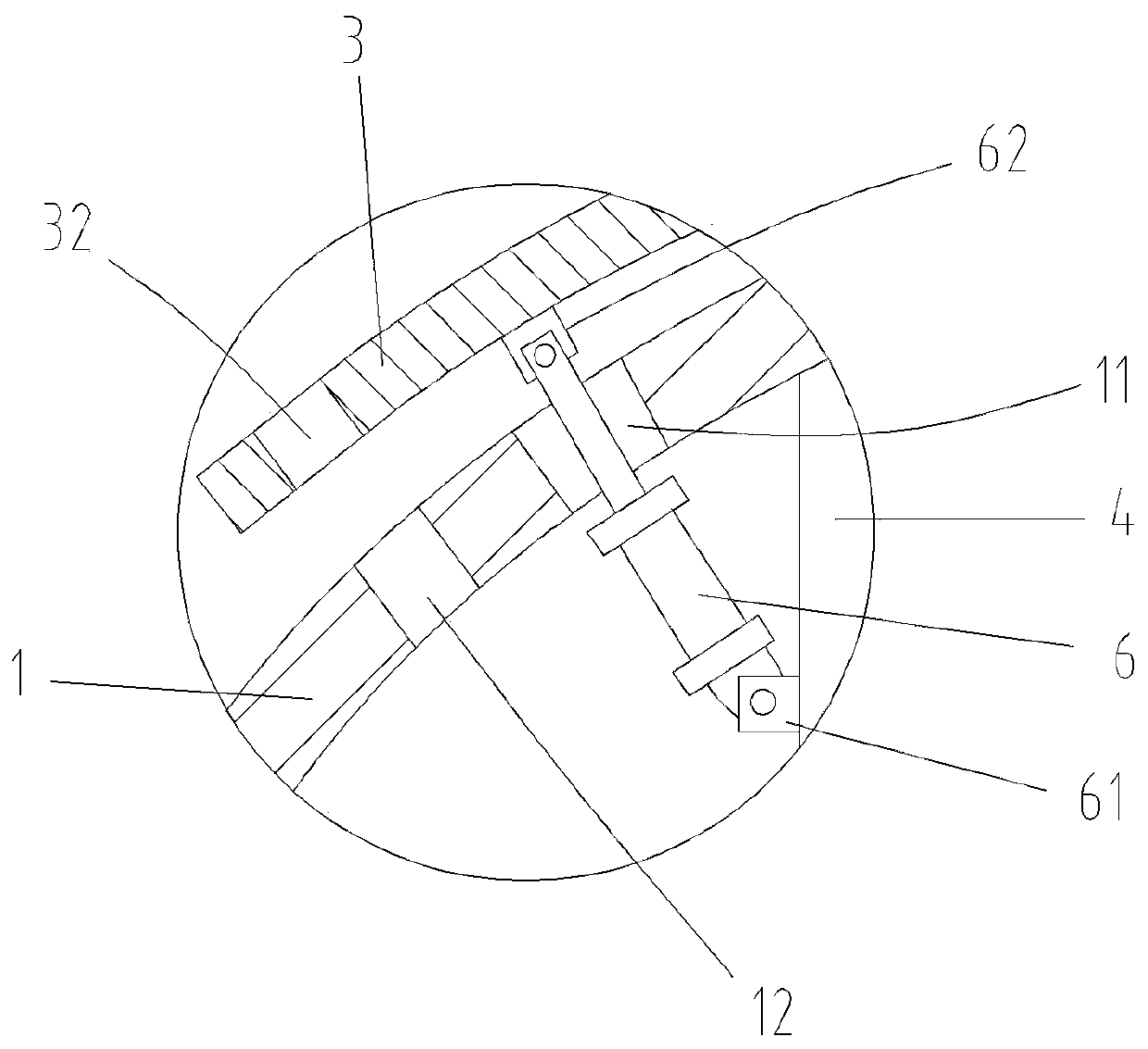

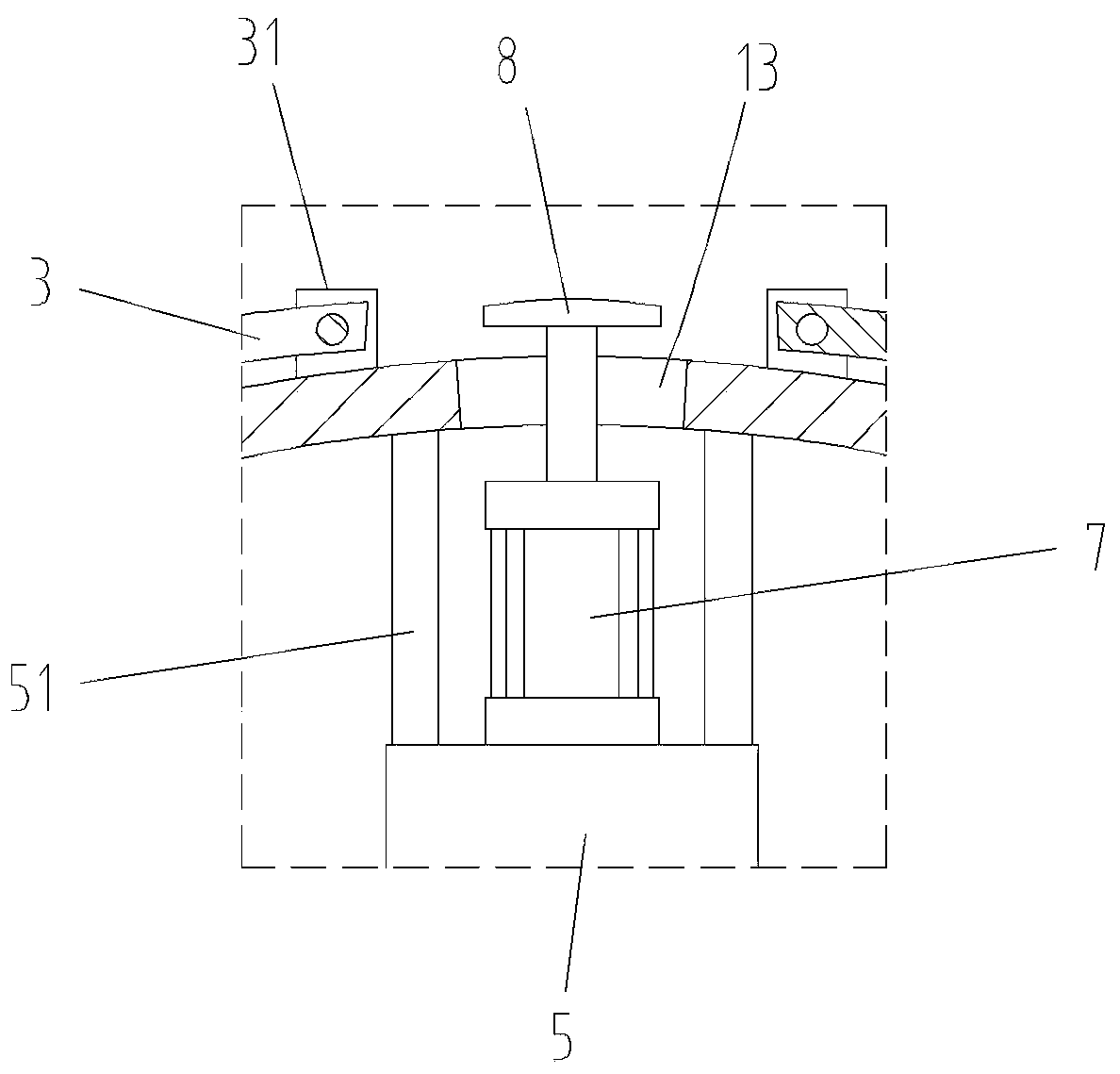

[0018] Such as Figure 1-Figure 3 As shown, a steel structure support structure provided by the present invention includes an arched plate 1, and the two ends of the arched plate 1 are respectively fixedly connected to the installation plate 14, and the arched plate 1 is conveniently fixed on the ground of the tunnel through the installation plate 14. superior. The arched plate 1 is supported and fixed by two vertical support columns 4, and both sides above the arched plate 1 are fixedly connected to the vertical plate 31, and one side of the vertical plate 31 is hinged to the arc-shaped plate 3. Provided with a relief hole 11, the first jack 6 is hinged through the first hinge seat 61 on one side of the support column 4, and the telescopic end of the first jack 6 passes through the relief hole 11. The telescopic end of the jack 6 is hinged to the arc plate 3 through the second hinge seat 62 .

[0019] A central hole 13 is provided at the center of the upper side of the arch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com