Moving explosive storage provided with liftable operation platform

A technology for operating platforms and explosives, which is applied in lifting frames, ammunition, lifting devices, etc., can solve problems such as short construction period, poor anti-knock performance, and potential safety hazards, and achieve good anti-knock performance, easy access, and shorten the safety effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

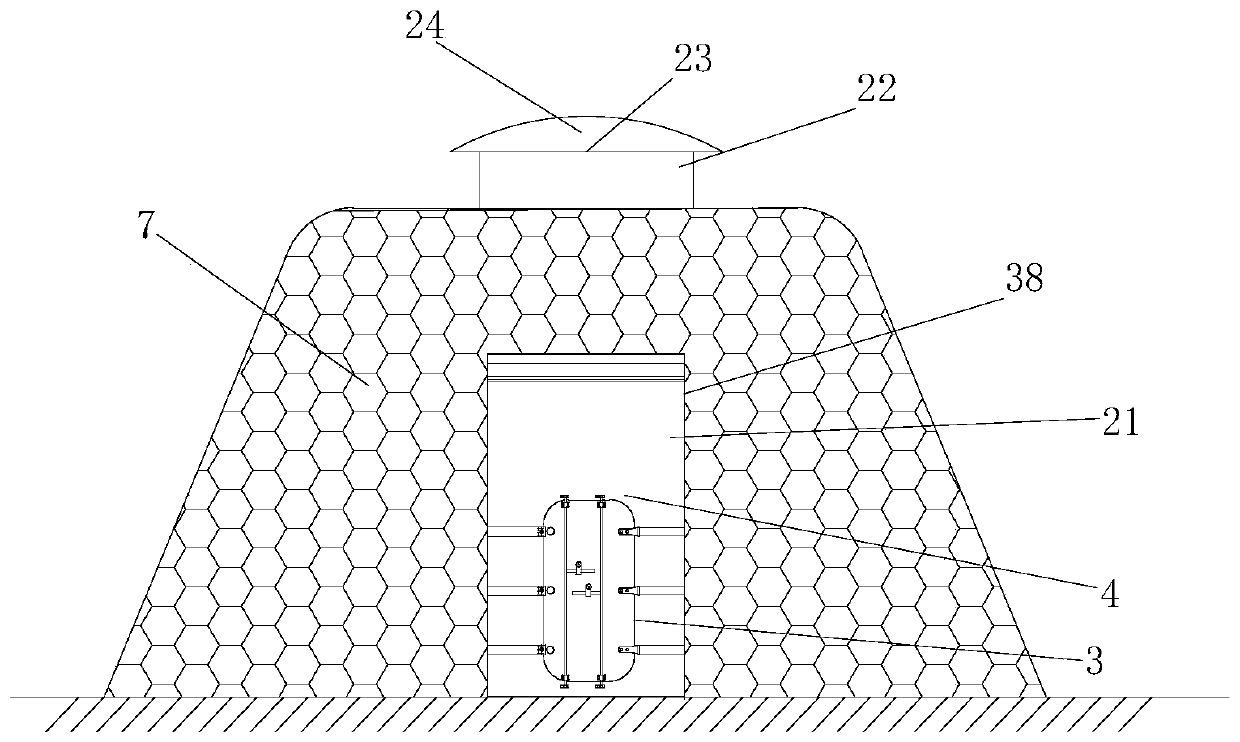

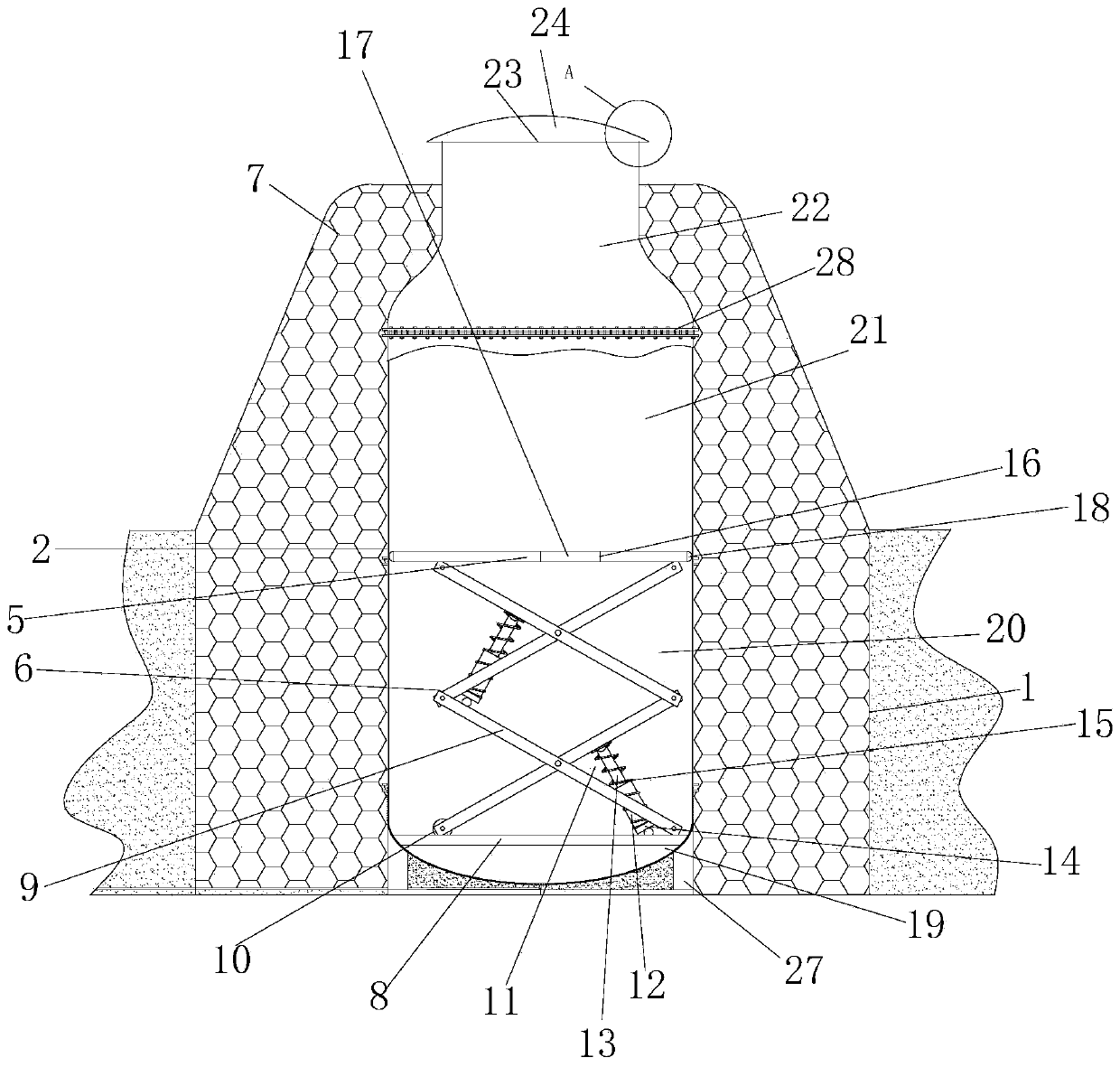

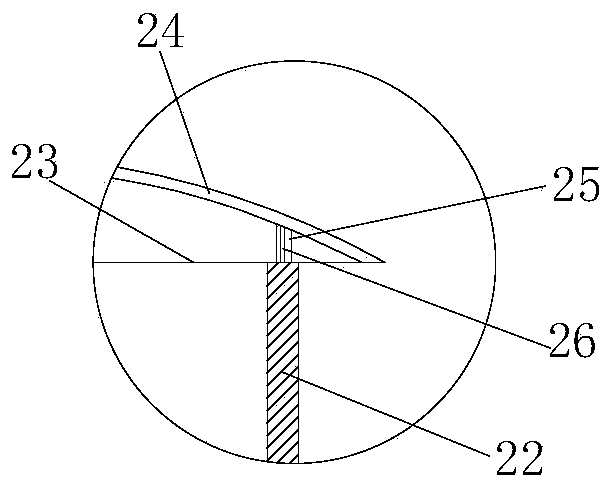

[0026] Such as Figure 1-6 As described above, a mobile explosive storehouse with a liftable work platform includes a bottom pit 1 on the ground and an explosive storehouse body 2 partially buried in the bottom pit 1, and an entrance is set on the explosive storehouse body 2 above the ground surface. The exit 3, the position of the entrance and exit 3 is provided with an explosion-proof door 4, and the inner cavity of the explosive storehouse body 2 is provided with an operating platform 5 for placing explosives, and is used to control the operation platform 5 in the inner cavity of the explosive storehouse body 2. The lifting mechanism 6 at the vertical height position, the outside of the explosive storehouse body 2 is stacked with a sandbag pile 7 arranged around the explosive storehouse body 2, and the lower half of the sandbag pile 7 is located below the ground surface and is located between the inner wall of the bottom pit 1 and the explosive storehouse body 2 Between the...

Embodiment 2

[0035] Such as Figure 7As shown, compared with Embodiment 1, the difference of Embodiment 2 is that the driving mechanism 11 includes a hydraulic cylinder 34, the cylinder body of the hydraulic cylinder 34 is hinged to the base 8, and the piston rod of the hydraulic cylinder 34 is connected to one of the X-shaped The boom 9 is hinged, and a control box for controlling the operation of the hydraulic cylinder 34 is fixed outside the explosive magazine body 2 . The control box controls the hydraulic cylinder 34 to work, and then can drive the lifting frame to expand or contract, so as to control the lifting of the operating platform 5 in the explosive store body 2, and control the operating platform 5 to rise upward when explosive items need to be taken, close to the explosion-proof The position at the bottom of the door 4 is convenient for workers to access and retrieve explosives. At other times, the operating platform 5 is located at the bottom of the inner cavity of the expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com