Method for nondestructively measuring bonding strength of coating interface by ultrasonic body wave phase spectrum

A technology that combines strength and ultrasonic waves at the interface. It is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measurement devices. It can solve difficult engineering applications, low quantitative accuracy, and complicated operations. problems, to achieve the effects of avoiding interference, wide application range, and simple engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

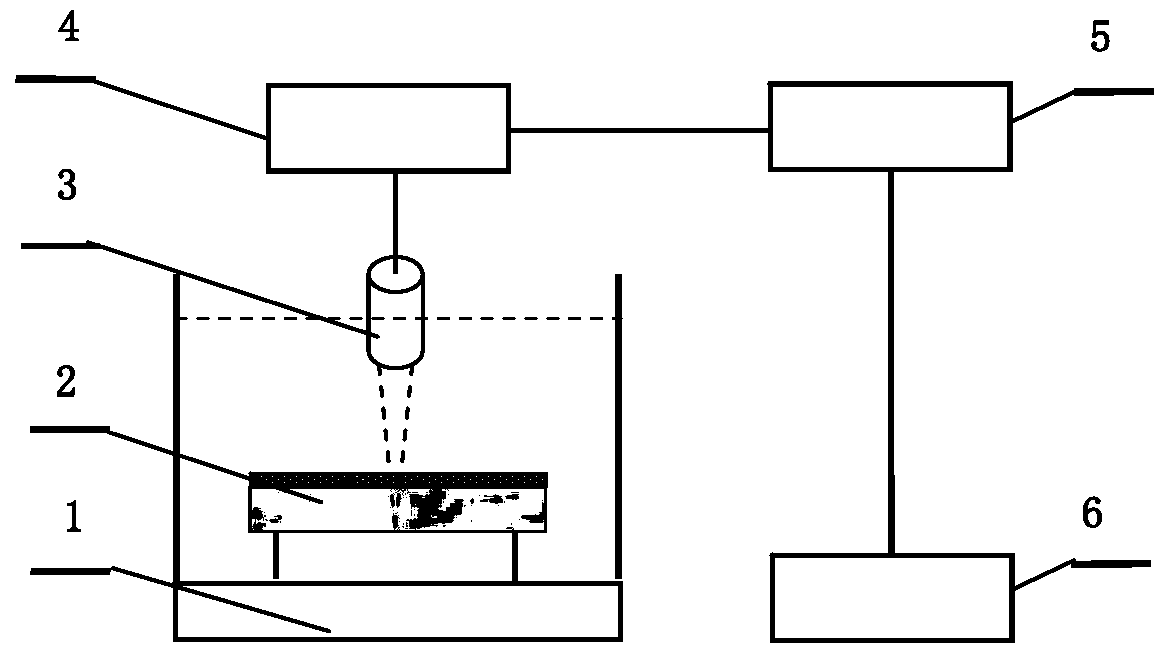

[0039] The detection system of the ultrasonic phase spectrum quantitative detection method for the bonding strength of the coating and the substrate interface consists of figure 1 The water tank 1 shown, the coating sample 2, the ultrasonic water immersion probe 3 with a nominal frequency of 5.0 MHz, the XYZ three-dimensional stepping device 4, the ultrasonic flaw detector 5 and the computer 6 are composed. It uses the following measurement steps:

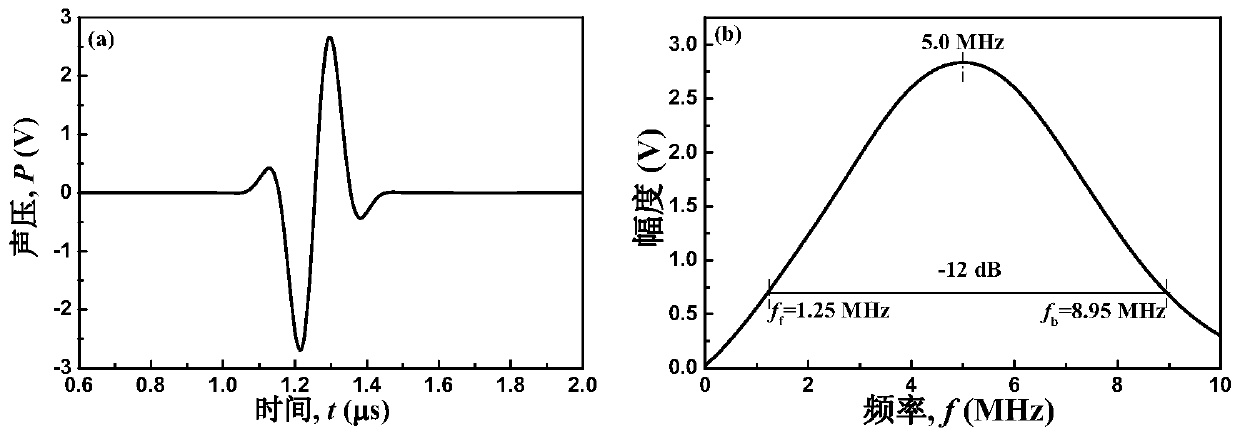

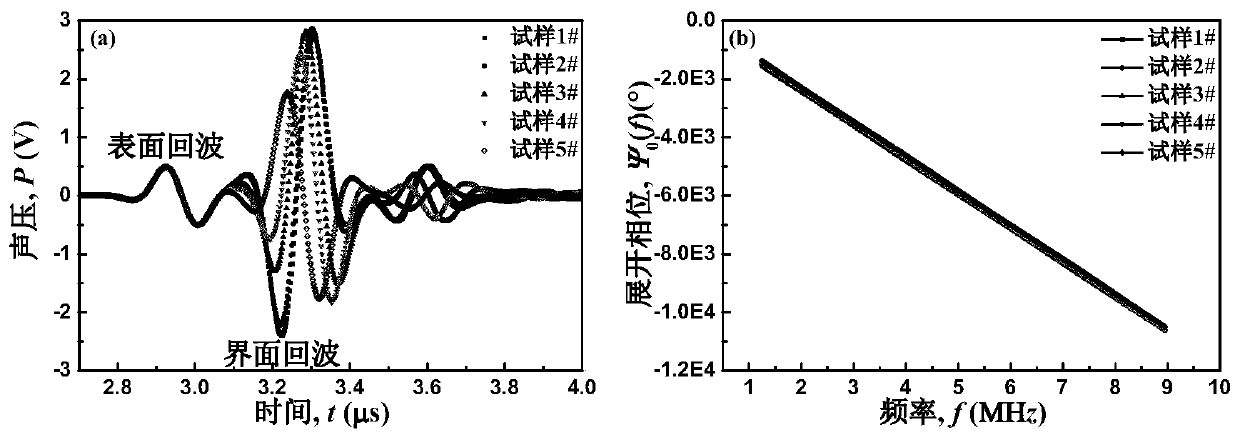

[0040] (1) Place the ultrasonic water immersion probe above the reference test block to ensure that the axis of the main sound beam of the probe is perpendicular to the surface of the test block; the ultrasonic wave is incident on the reference test block through the coupling medium in the water tank, and the reflection echo signal on the surface of the reference test block is collected. A scan waveform P 0 (t), such as figure 2 (a), t is time, the unit is second, for P 0 (t) Perform fast Fourier transform to obtain its power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com