Upward and downward conveying mechanism used for testing of electronic control units of automobile engine

An electronic control unit, automotive engine technology, applied in electrical testing/monitoring, program control, general control systems, etc., can solve problems such as affecting work efficiency, unable to synchronize, and occupying a large area, reducing labor costs and reducing equipment. Width, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with embodiments.

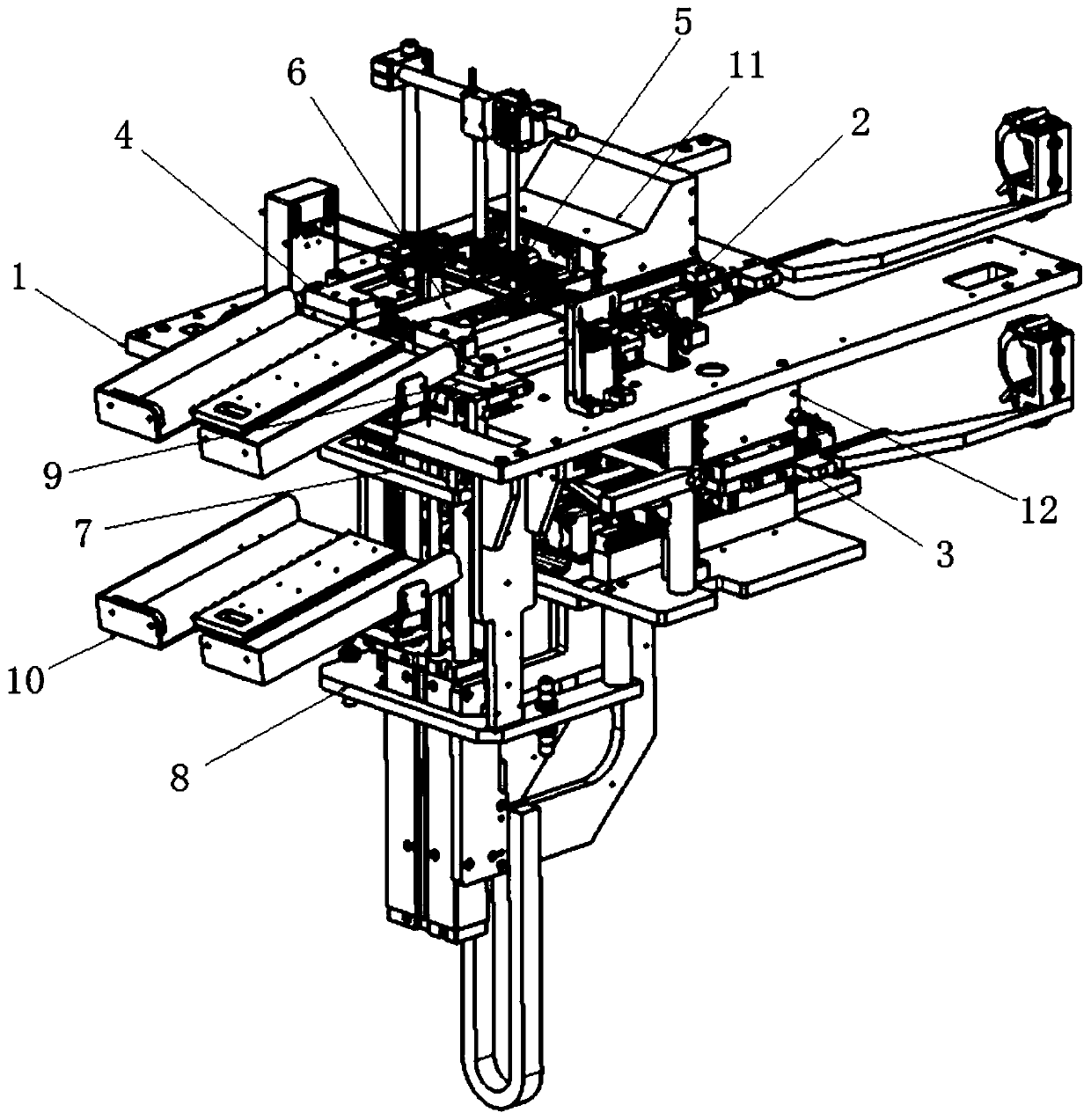

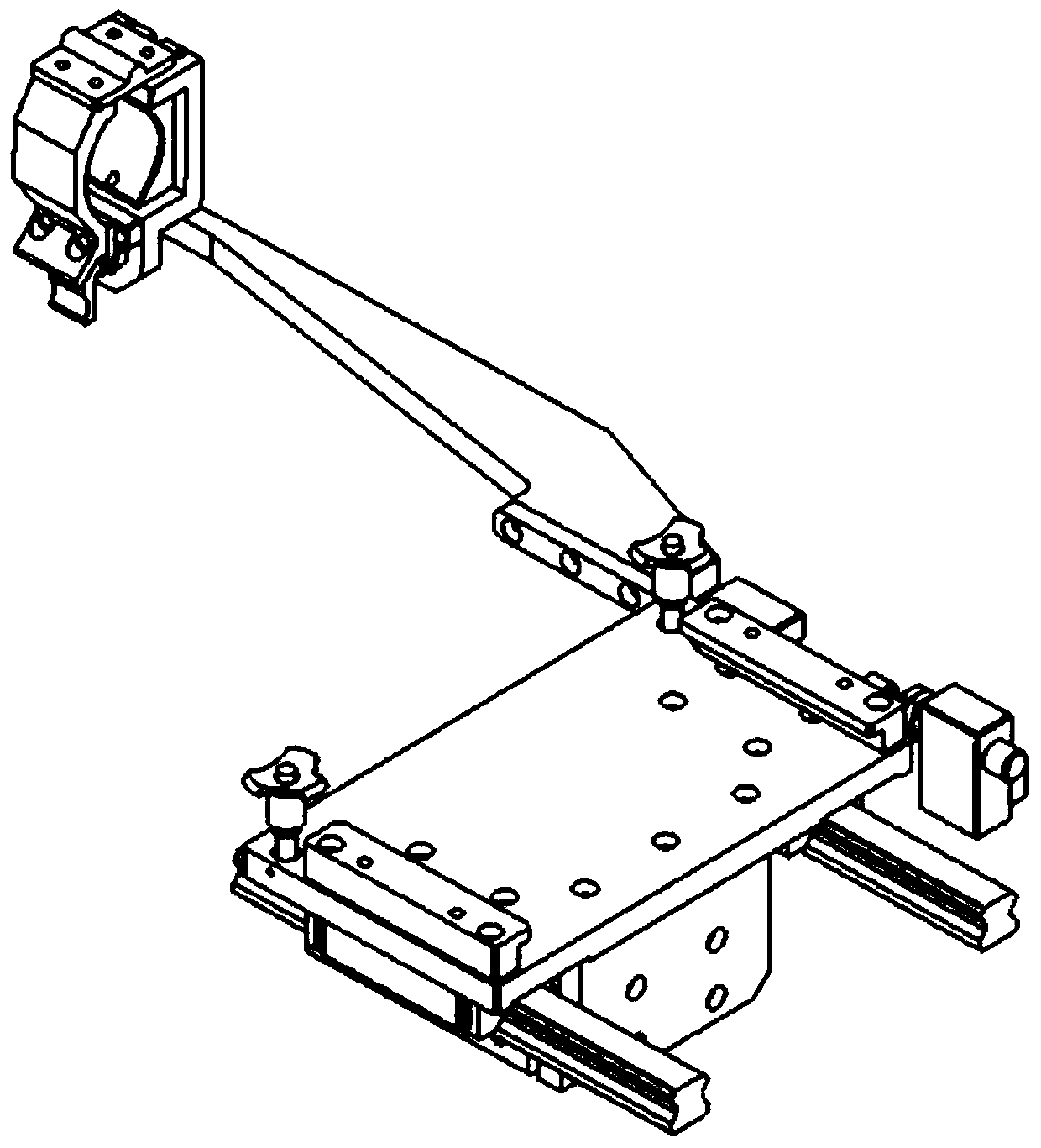

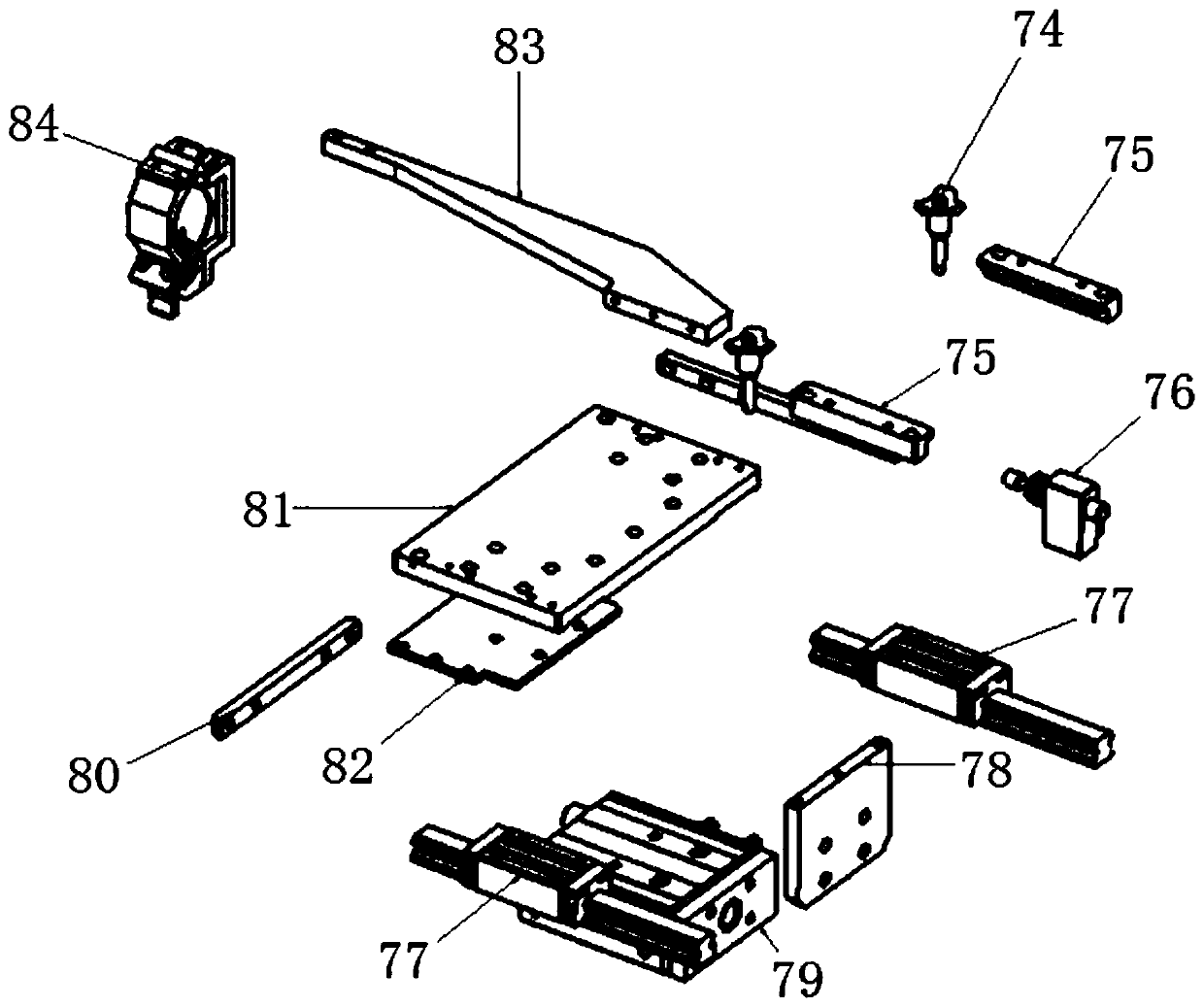

[0050] Such as Figure 1-13 The upper and lower transmission mechanism shown for the test of the electronic control unit of the automobile engine includes:

[0051] The main board 1 forms a cubic closed body with an upper and lower two-layer structure through the connecting board and the connecting column;

[0052] The upper station includes the left and right fixtures 4 and 5 that move left and right. The electronic control unit of the automobile engine uses its product shape to position the left fixture 4 and the right fixture 5. After positioning, the upper push unit 2 drives the RUNIN test head 11 and The RUNIN test is completed after the connection of the electronic control unit of the automobile engine; after the upper-layer test is completed, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com