Nano zero-valent iron-nickel composite material prepared on basis of laterite-nickel ore and preparation method of nano zero-valent iron-nickel composite material

A nano-zero-valent iron and laterite nickel ore technology is applied in the fields of nanotechnology, nanotechnology, nanotechnology and other fields for materials and surface science, which can solve the problems of low activity of granular materials and complex processes, and achieve low production cost, The effect of high reaction efficiency and improved catalytic oxidation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

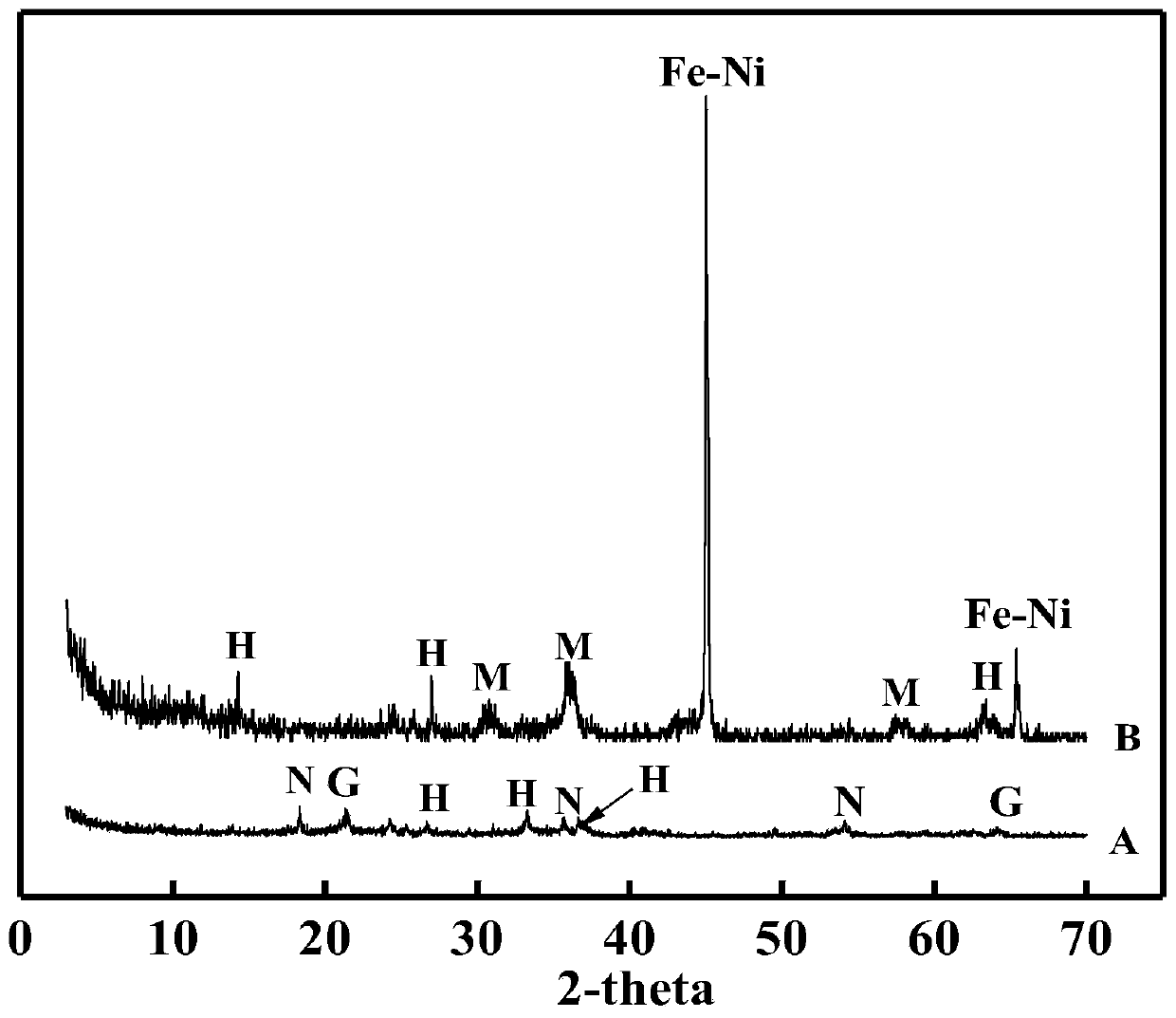

[0054] The preparation of the nanometer zero-valent iron-nickel composite material described in this embodiment comprises the following steps:

[0055] 1.1 Crush and screen the laterite nickel ore to obtain granular materials with a particle size of <0.0374mm;

[0056] 1.2 Add 8mmol of the granular material into a three-necked flask, add 100mL of 90% ethanol solution into the three-necked flask and stir for 20h, then filter and centrifuge, wash with deionized water twice, and dry it in an oven to obtain The laterite nickel ore powder; then add 80mL of 1mol / L potassium borohydride or sodium borohydride solution into the three-necked flask to the laterite nickel ore powder, stir for 2 hours, and suction filter to obtain the precipitate, and the obtained precipitate The materials were washed with absolute ethanol, then sucked dry, and dried in a vacuum oven to obtain the nanometer zero-valent iron-nickel composite material.

Embodiment 2

[0058] The preparation of the nanometer zero-valent iron-nickel composite material described in this embodiment comprises the following steps:

[0059] 2.1 Crush and screen the laterite nickel ore to obtain granular materials with a particle size of <0.0374mm;

[0060] 2.2 Add 8 mmol of the granular material into a three-necked flask, add 100 mL of 90% ethanol solution into the three-necked flask and stir for 24 hours, then filter and centrifuge, wash with deionized water for 4 times, and dry it in an oven to obtain The laterite nickel ore powder; then add 80mL of 20mol / L potassium borohydride or sodium borohydride solution into the three-necked flask to the laterite nickel ore powder, stir for 10h, and suction filter to obtain the precipitate, and the obtained precipitate The materials were washed with absolute ethanol, then sucked dry, and dried in a vacuum oven to obtain the nanometer zero-valent iron-nickel composite material.

Embodiment 3

[0062] The preparation of the nanometer zero-valent iron-nickel composite material described in this embodiment comprises the following steps:

[0063] 3.1 Crush and screen the laterite nickel ore to obtain granular materials with a particle size of <0.0374mm;

[0064] 3.2 Add 8 mmol of the granular material into a three-necked flask, add 100 mL of 90% ethanol solution into the three-necked flask and stir for 22 hours, then perform filtration and centrifugation, wash with deionized water for 3 times, and dry it in an oven to obtain The laterite nickel ore powder; then add 80 mL of 15 mol / L potassium borohydride or sodium borohydride solution to the laterite nickel ore powder into a three-necked flask, stir for 5 hours, and suction filter to obtain a precipitate, and the obtained precipitate The materials were washed with absolute ethanol, then sucked dry, and dried in a vacuum oven to obtain the nanometer zero-valent iron-nickel composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com