Rubber-covered wire jumper connector plug assembly process and assembly equipment

A technology for connector plugs and leather jumpers, which is applied in the field of assembly technology and assembly equipment for leather jumper connectors, can solve the problems of low work efficiency and high work intensity, reduce labor intensity, improve work efficiency, The effect of reducing labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing:

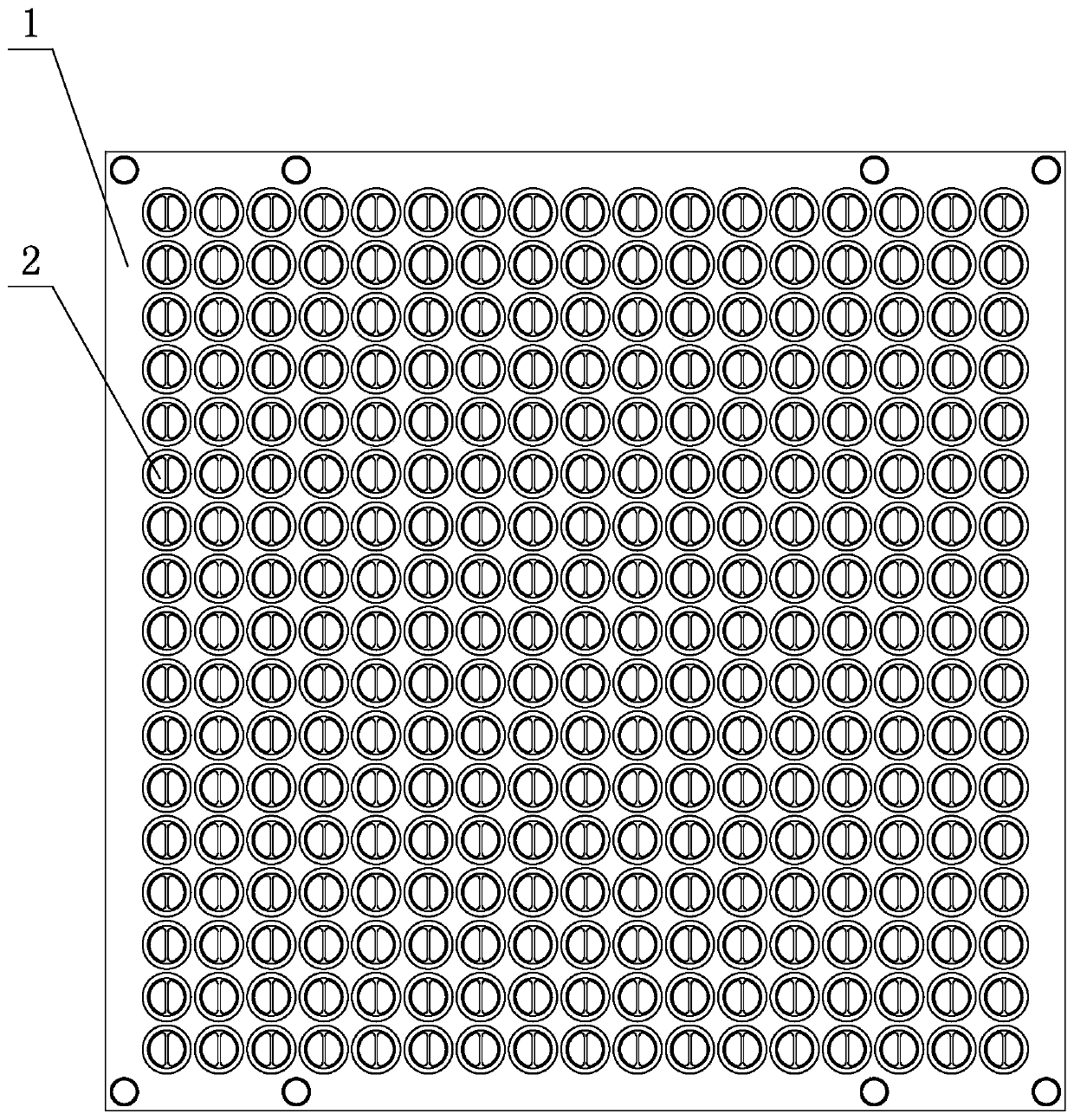

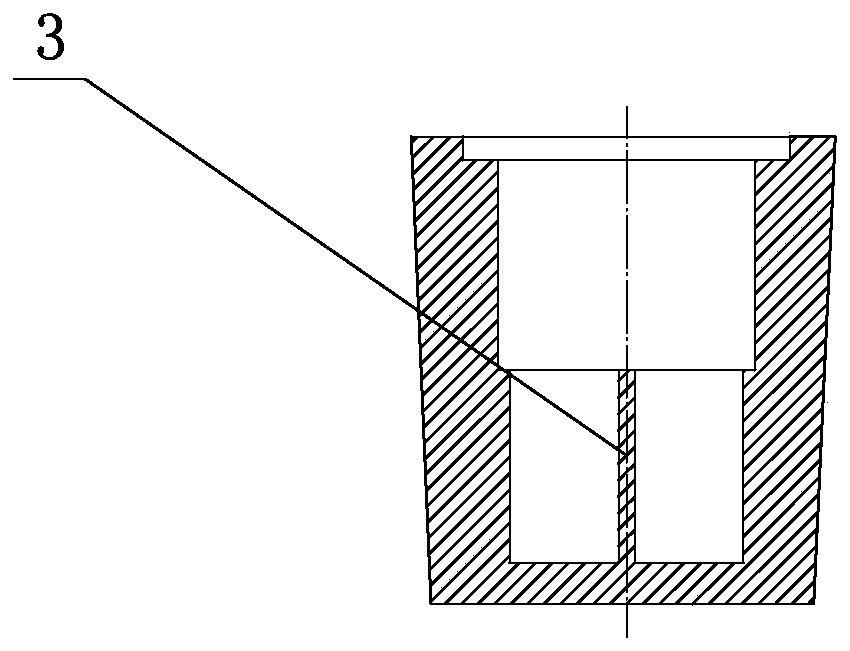

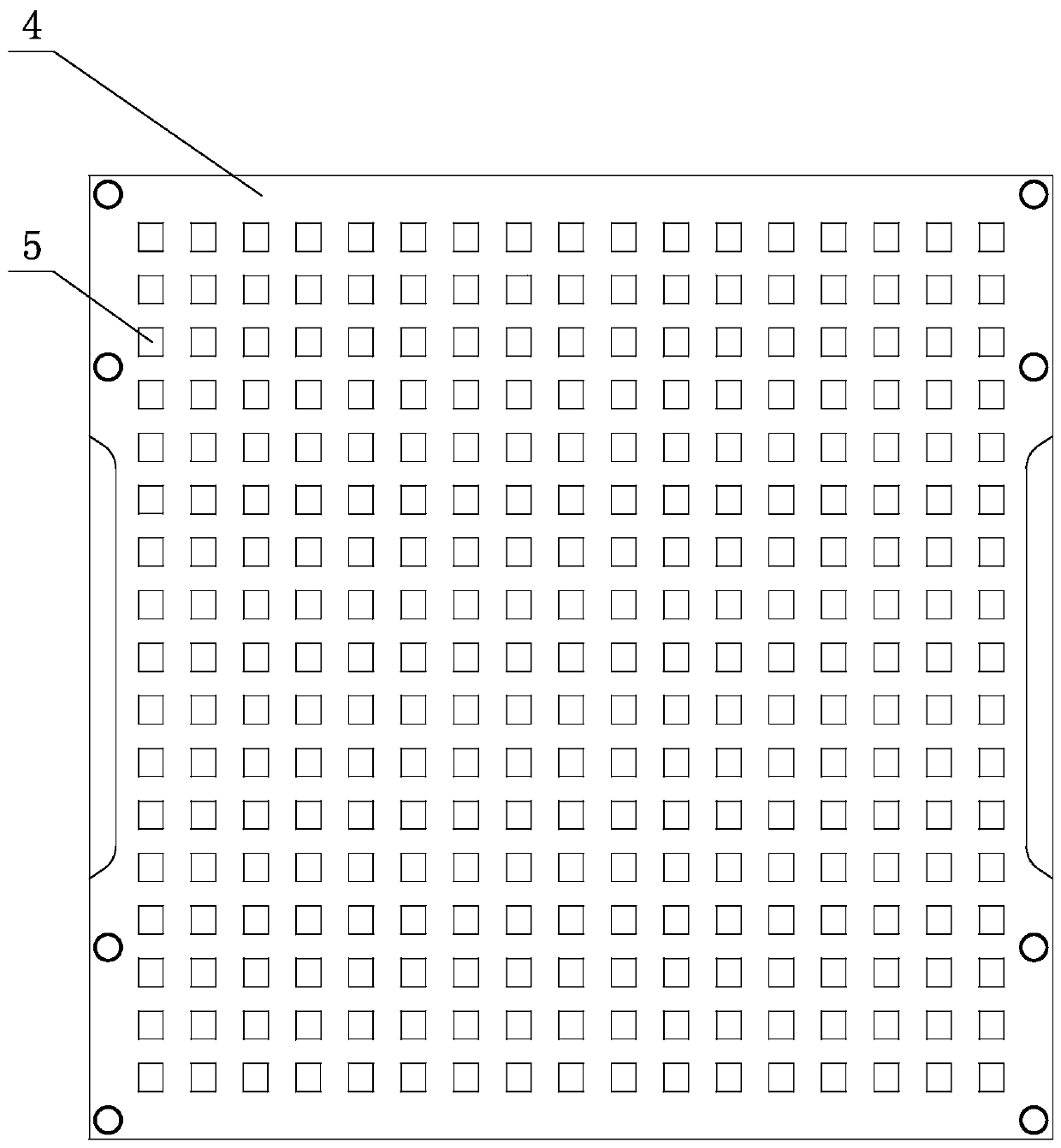

[0054] Such as Figure 1-Figure 21 , the jumper connector plug assembly process described in this embodiment, the specific steps are as follows,

[0055] Step 1, the white shell board, core plate and sleeve plate are respectively placed on the white shell vibrating station 40, the ceramic ferrule vibrating station 44 and the supporting sleeve vibrating station 52 of the assembly equipment, and then the material white shell, ceramic The ferrule and the supporting sleeve are respectively laid on the white shell board, the ferrule board and the casing board, the motor 31 is started, the material vibrates with the vibrating frame 37, and the material is gradually screened into the corresponding jack, and the vibration time is 10s- 30s;

[0056] Step 2, take the white shell plate filled with white shell to the operation platform area 49, then take the transition plate one, buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com