Vacuum long pipe valve and working method thereof

A long-tube, vacuum technology, applied in bottle filling, liquid bottling, packaging, etc., can solve the problem of high oxygen increase in filling valves, and achieve the effects of simple flow channels, easy cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

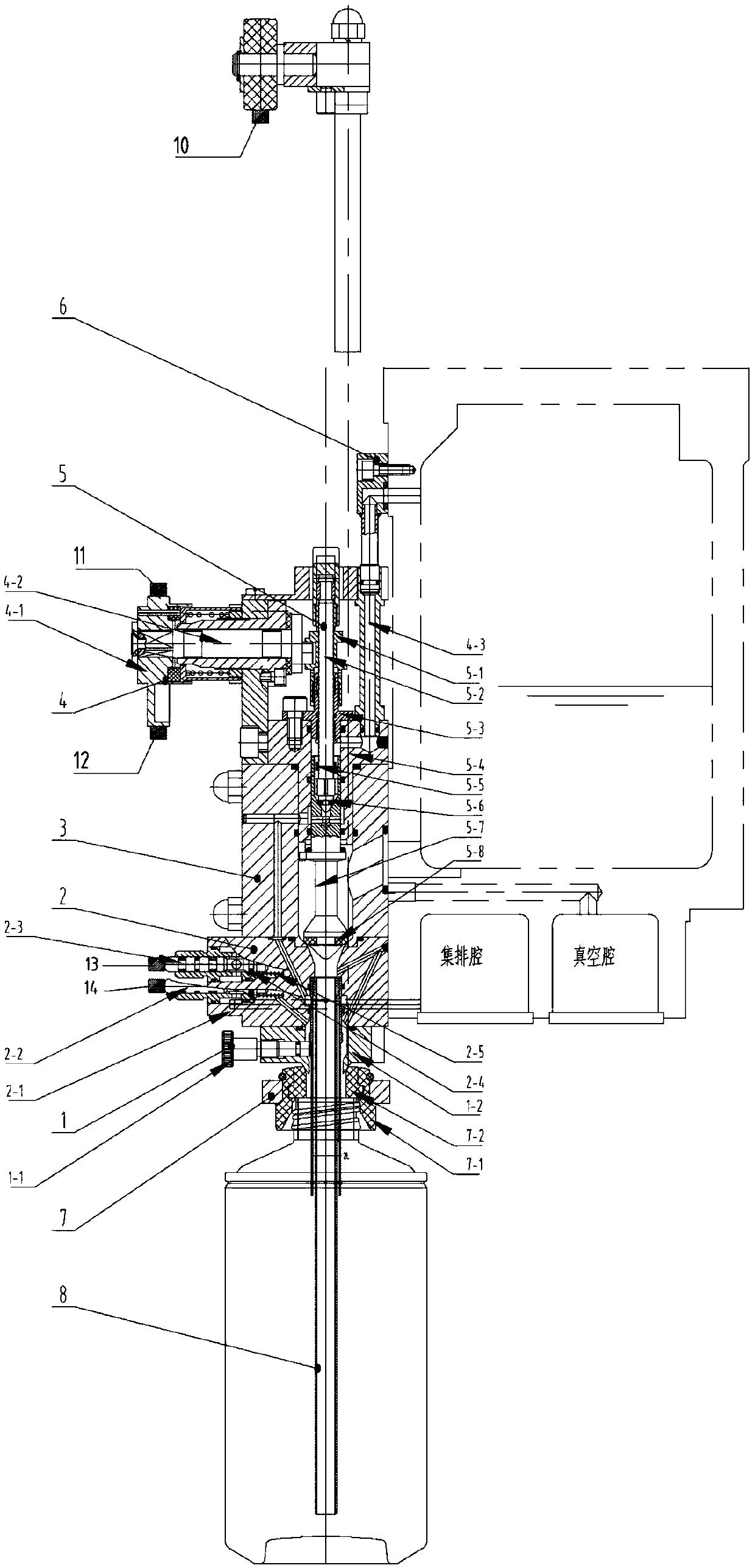

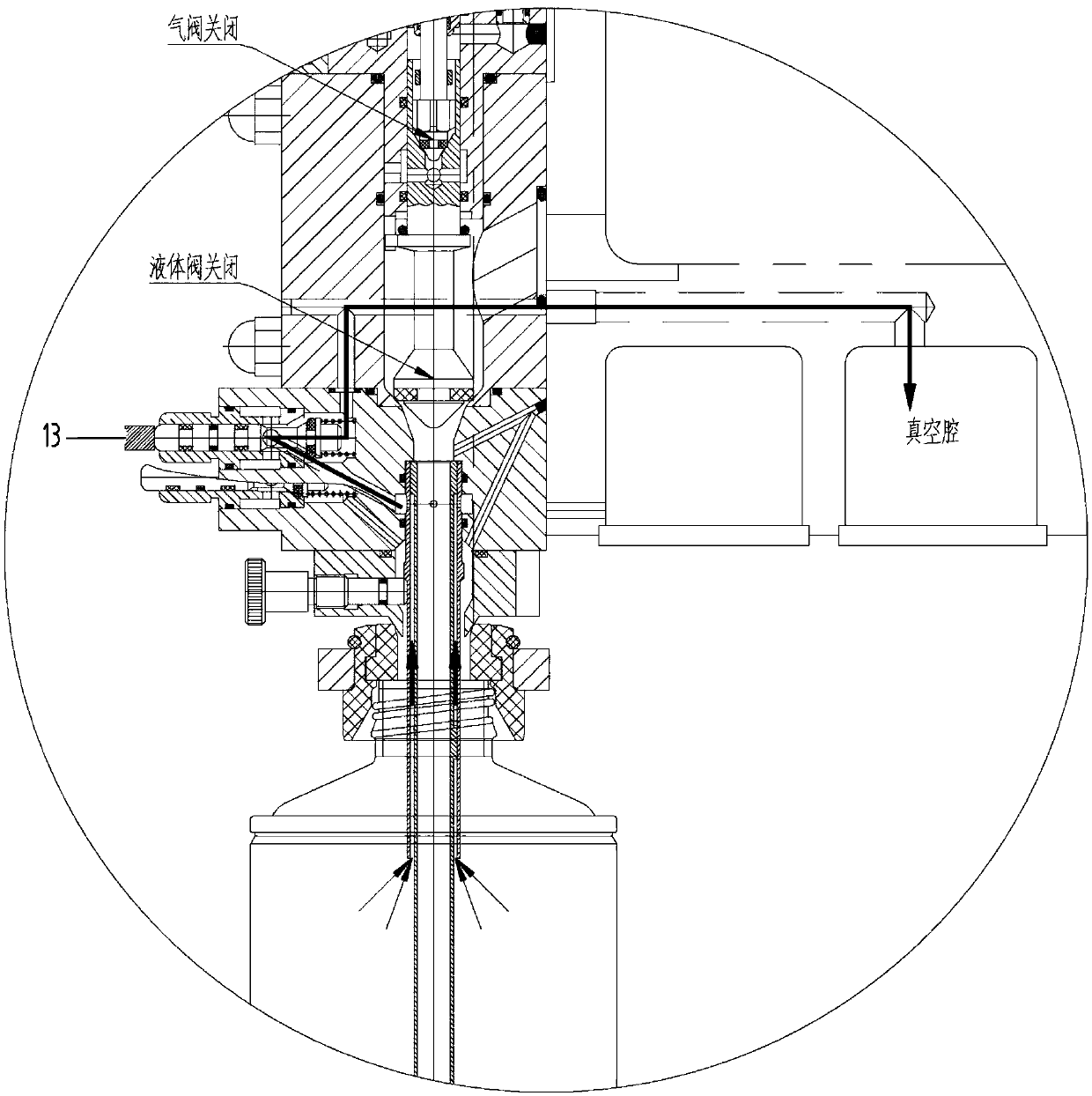

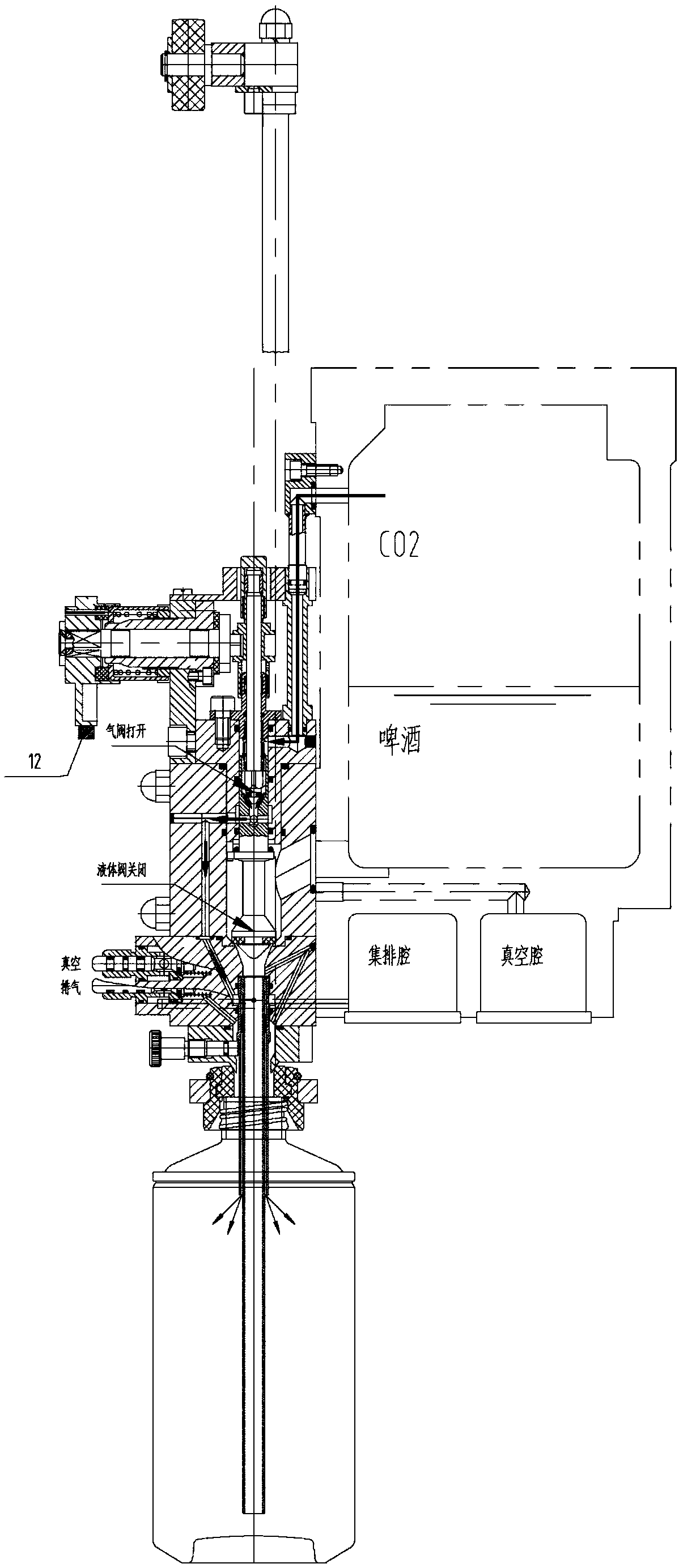

[0048] Such as figure 1 , a vacuum long tube valve, including a long tube 8 for inserting into a metal bottle and a return air tube seat 1 for fixing the long tube 8, the return air tube seat 1 includes a fixed seat 1-2, a fixed seat 1-2 and The long pipes 8 are fixedly connected by locking screws 1-1, and the lower valve base 2 for providing gas switching channels and material channels is fixed above the fixed seat 1-2. The valve lower base 2 includes the valve lower base 2-1, the valve A valve main body 3 for setting gas channels and material channels is fixed above the lower seat 2-1. The long tube 8 is a double-layer long tube, the outer layer of the long tube 8 is shorter than the inner layer, and the center of the inner layer of the long tube 8 is a material channel. The interlayer between the outer layer and the inner layer is the gas channel;

[0049] The valve lower seat 2-1 and the valve main body 3 are provided with a first channel in communication, the first chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com