Dustproof rod end joint bearing and dustproof rod end joint bearing production method

A production method and technology of end joints, applied to bearings, shafts, bearings, bearing components, etc., can solve problems such as poor reliability and easy falling off of sealing covers, and achieve the effects of high reliability, simple structure, and guaranteed sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 of the dust-proof rod-end joint bearing in the present invention: the dust-proof rod-end joint bearing in the present invention can effectively block the intrusion of dust and the like between the inner ring of the bearing and the outer ring of the bearing through the dust-proof cover arranged on it. The working surface of the bearing reduces the wear of the working surface of the bearing and improves the service life of the bearing.

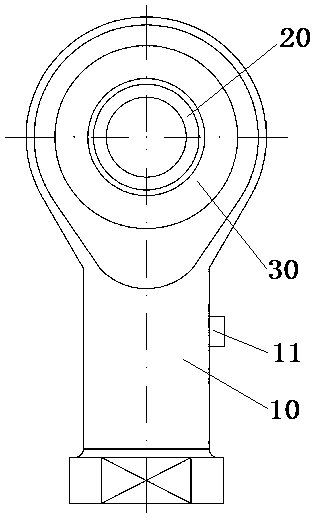

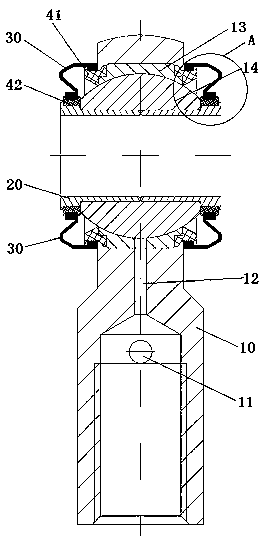

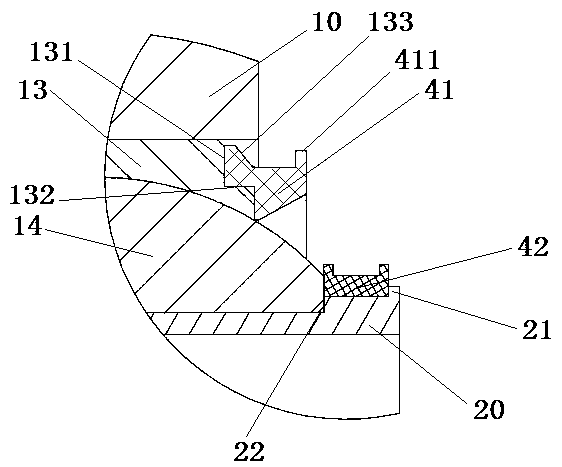

[0062] Such as figure 1 and figure 2 As shown, the main components of the dust-proof rod end joint bearing include a rod end body 10. The rod end body 10 has the same structure as the rod end body of other rod end joint bearings in the prior art. A bearing outer ring 13 is installed in the end hole, and the bearing outer ring 13 is relatively fixedly arranged with the rod end body 10 . A bearing inner ring 14 is movable in the bearing outer ring 13. There is a spherical fitting surface between the bearing outer ring 13 and...

Embodiment 2

[0083] Embodiment 2 of the dust-proof rod end joint bearing in the present invention: the difference from the above embodiment is that the axis of the fixed support ring in this embodiment no longer coincides with the axis of the outer ring of the bearing, and the two are arranged in a manner parallel to the axis , the normal line of the fixed mating surface on the fixed support ring is perpendicular to the axis of the fixed support ring.

Embodiment 3

[0084] Embodiment 3 of the dust-proof rod end joint bearing in the present invention: the difference from the above embodiments is that the fixed mating surface on the fixed support ring in this embodiment is located on the inner peripheral surface of the fixed support ring, and is not limited to The scheme of arranging the fixed mating surface on the outer peripheral surface of the fixed support ring is adopted; or the fixed mating surface is arranged on both the inner peripheral surface and the outer peripheral surface, so as to improve the applicability of the fixed support ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com