Hasp type radiator edge plate

A radiator and side plate technology, applied in the field of snap-on radiator side plates, can solve problems such as insufficient release of radiator stress, reduced service life of the radiator, and weakening of the surrounding strength of the mounting hole, etc., to achieve a simple and effective internal Stress, prolong service life, improve the effect of welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

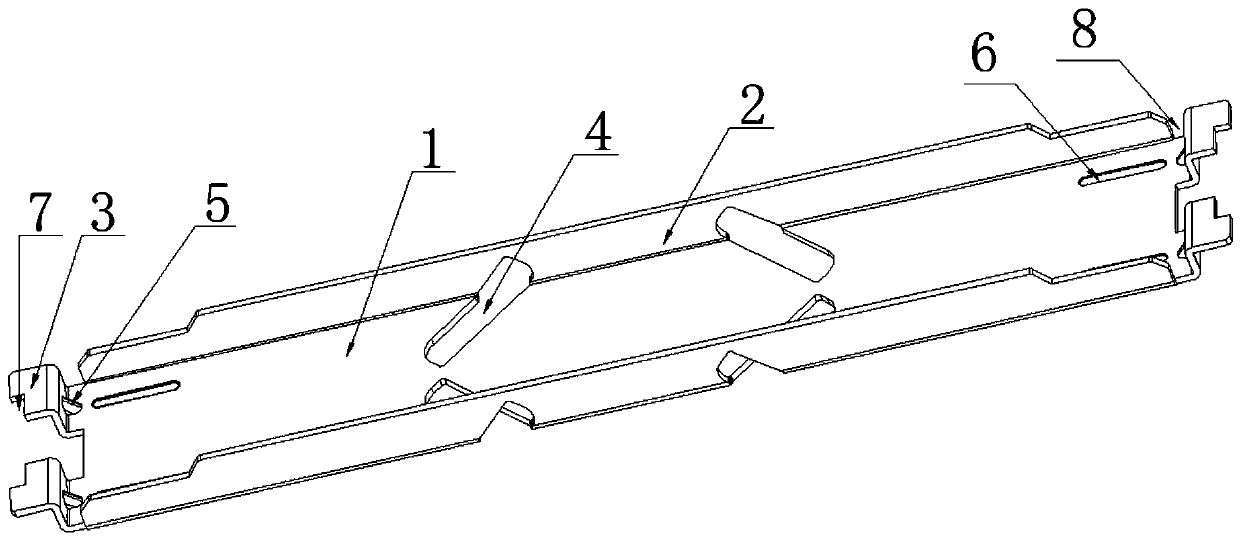

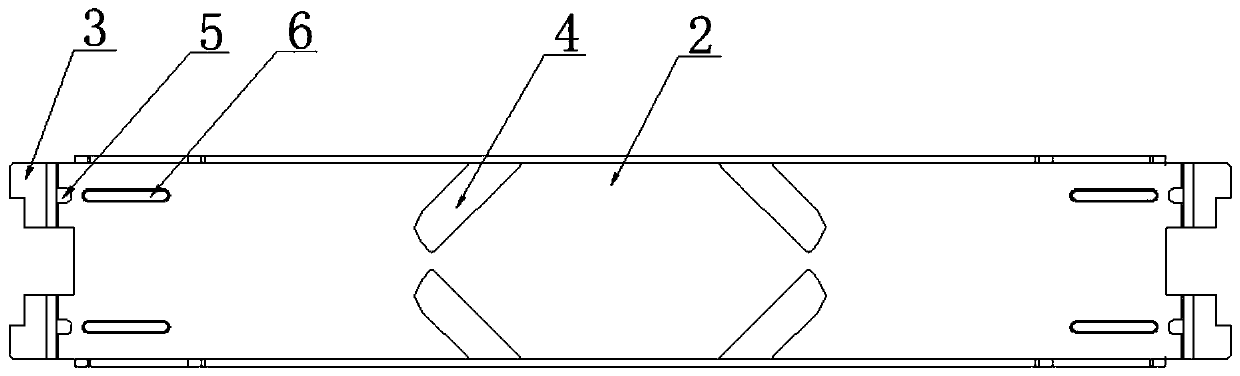

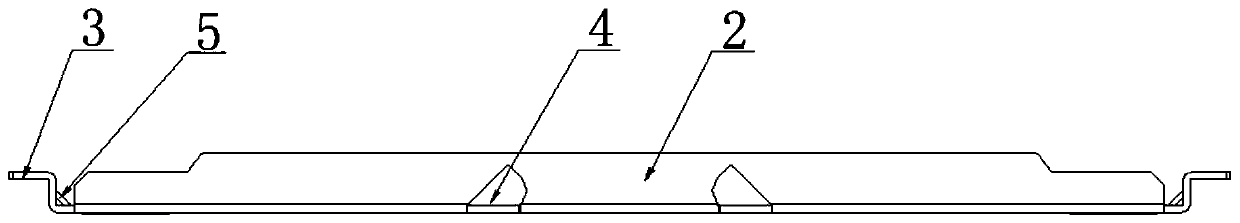

[0027] This embodiment provides a buckle type radiator side plate, its structure is detailed in the attached Figure 1-3 As shown: it includes a welding panel 1, the two sides of the long side of the welding panel 1 are bent vertically upwards to form a flap 2, the two sides of the short side of the welding panel 1 are bent vertically upwards and the top is vertically folded to the outside of the welding panel 1 Bend to form a pressure head 3, the welding panel 1 and the turning plate 2 are provided with grooves, and the welding panel 1 and the turning plate 2 communicate with the grooves to form an expansion groove 4. Expansion grooves allow the product to effectively and timely release internal stress, prevent expansion and deformation of the radiator, and prolong the service life of the radiator.

[0028] Further, one indenter 3 is respectively provided on the two short sides of the welding panel 1 . When the length of the short side of the welding panel is relatively shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com