Miniature easy-to-branch rat-proof photoelectric composite cable for wireless small base station and preparation method of composite cable

A photoelectric composite cable and easy branching technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, flat/ribbon cables, etc., can solve the problems of increasing the cost of using optical cables, high cost of armoring materials, and heavy weight of optical cables, etc. Effect of designing cost and weight, realizing branch design, speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

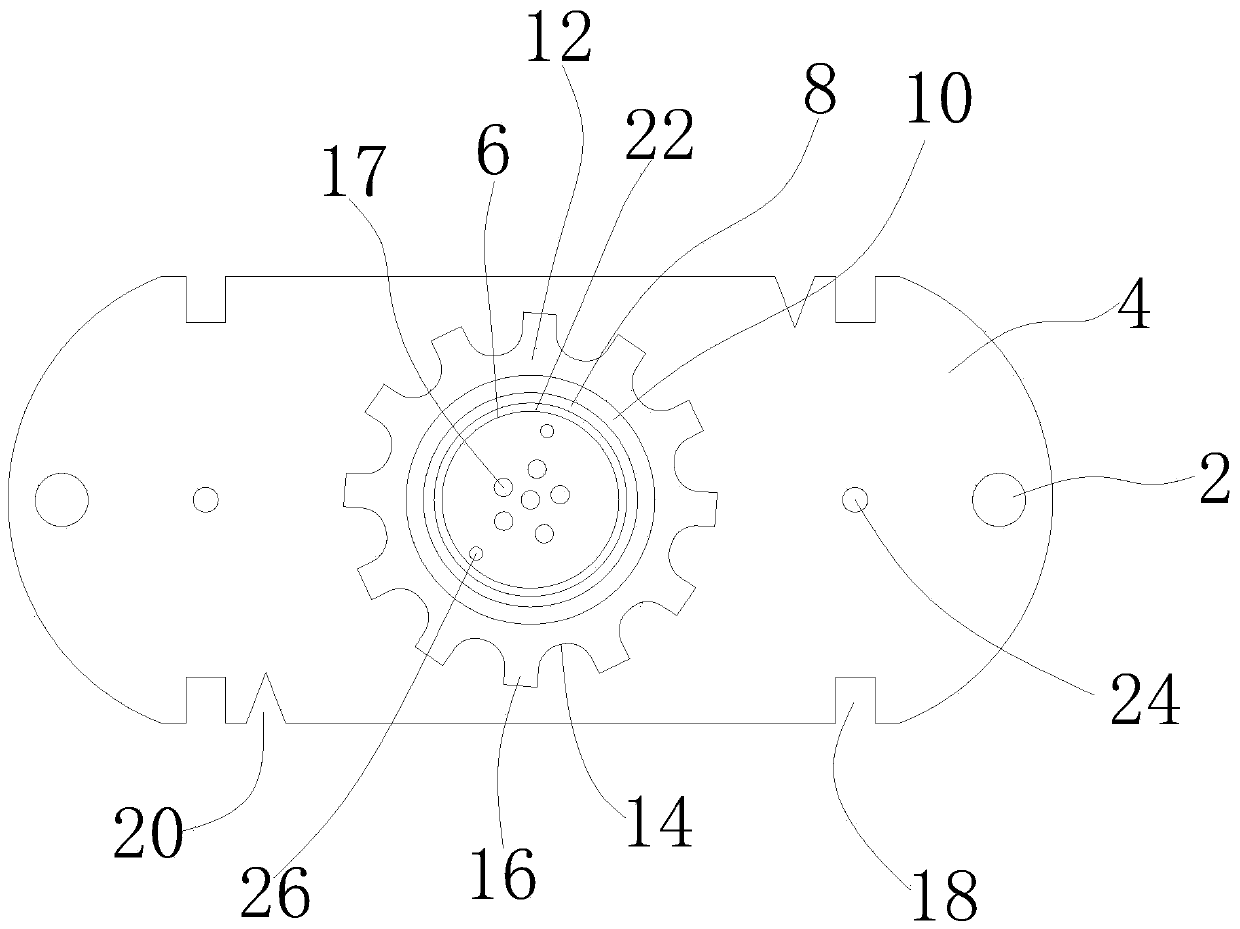

[0033]This embodiment provides a miniature easy-to-branch anti-rodent photoelectric composite cable for wireless small base stations. The outer sheath 4 of the light-covering unit and the electrical unit 2 . The optical unit is located in the center, and two sets of electrical units 2 are symmetrically arranged on both sides of the optical unit with the optical unit as the center. A reinforcing member 24 parallel to both is arranged between the optical unit and the electrical unit. The optical unit, the electrical unit and the reinforcement The centers of the three pieces are on the same straight line. In the technical solution of this embodiment, the above-mentioned reinforcing member 24 is a high-carbon phosphating steel wire or a non-metallic glass fiber reinforced rod. The outer sheath 4 is provided with a sling 18 between the optical unit and the electrical unit, and the sling is used as a tear opening of the electrical unit, which is produced when the electrical unit te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com