Easy-cleaning long-life elastic contact structure

An elastic contact and long-life technology, which is applied to contact parts, parts of connection devices, connections, etc., can solve problems such as contact failure, contact part wear, and contact plating peeling off, so as to improve work reliability and maintain contact Reliability, the effect of avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

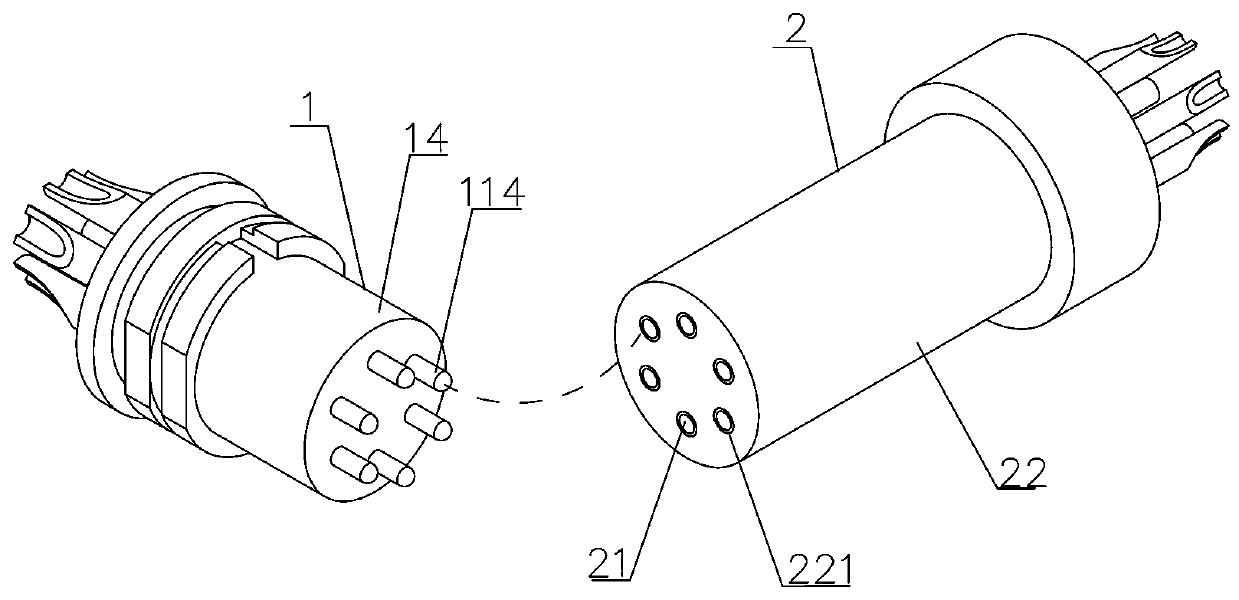

[0024] refer to figure 1 , the present invention includes a pin base assembly 1 and a socket base assembly 2 .

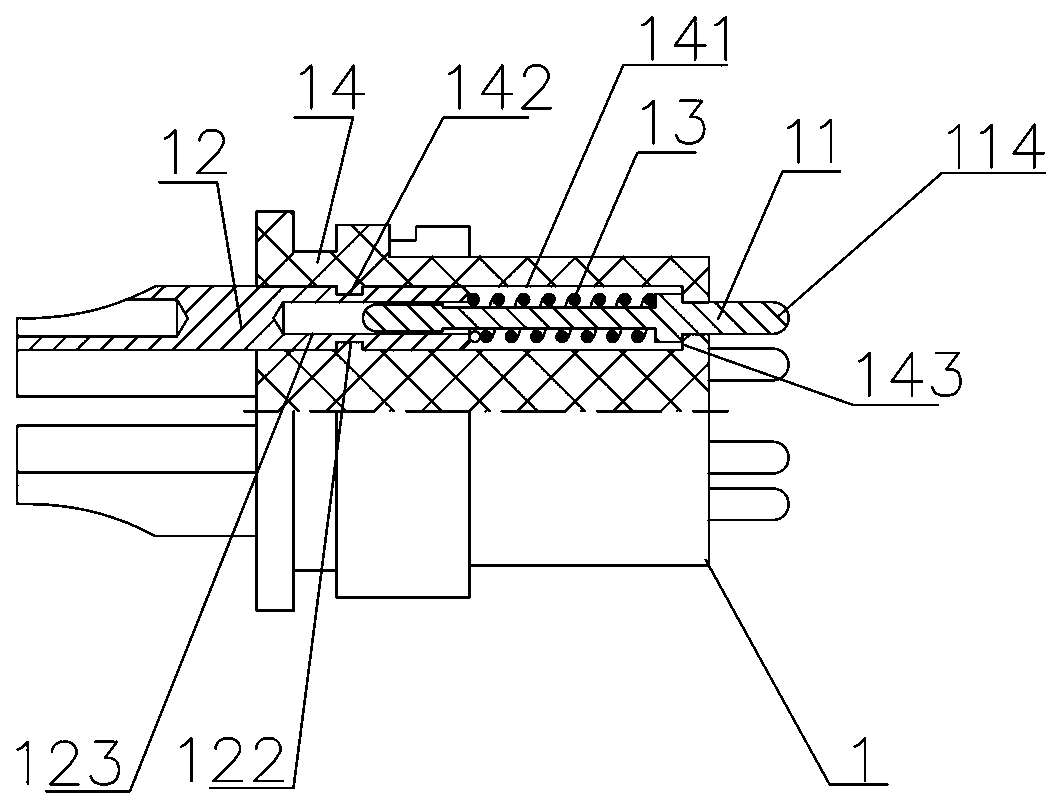

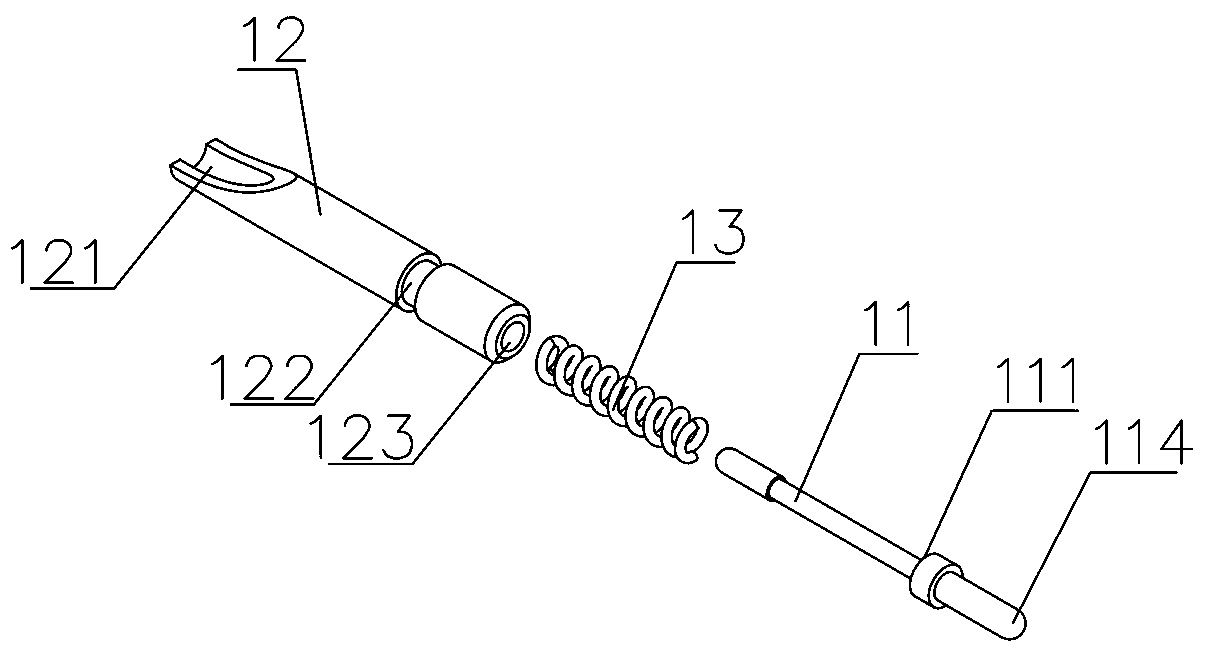

[0025] refer to figure 1 , figure 2 , image 3 , the pin base assembly 1 is composed of a pin contact 11, a pin sleeve 12, a spring 13, and a pin base 14;

[0026] The pin base 14 is a cylindrical member, on which several pin holes 141 are arranged along the circumference, and a convex rib 142 is arranged in the pin hole 141, and a stop ring 143 is provided at the port of the pin hole 141;

[0027] The pin sleeve 12 is a rod member with a shaft hole 123 at one end and a welding cup 121 at the other end, and a groove 122 is provided on the shaft;

[0028] The pin contact 11 is a bar member provided with a step 111, and the contact end of the pin contact 11 is a semicircular ball end 114;

[0029] The other end of the pin contact 11 is set in the shaft hole 123 of the pin sleeve 12, and the spring 13 is set between the pin contact 11 and the pin sleeve 12 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com