A corner disinfection device for hygiene management

A technology for disinfection equipment and corners, applied in sanitary equipment, disinfection, construction and other directions for toilets, which can solve problems such as inability to disinfect dead corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

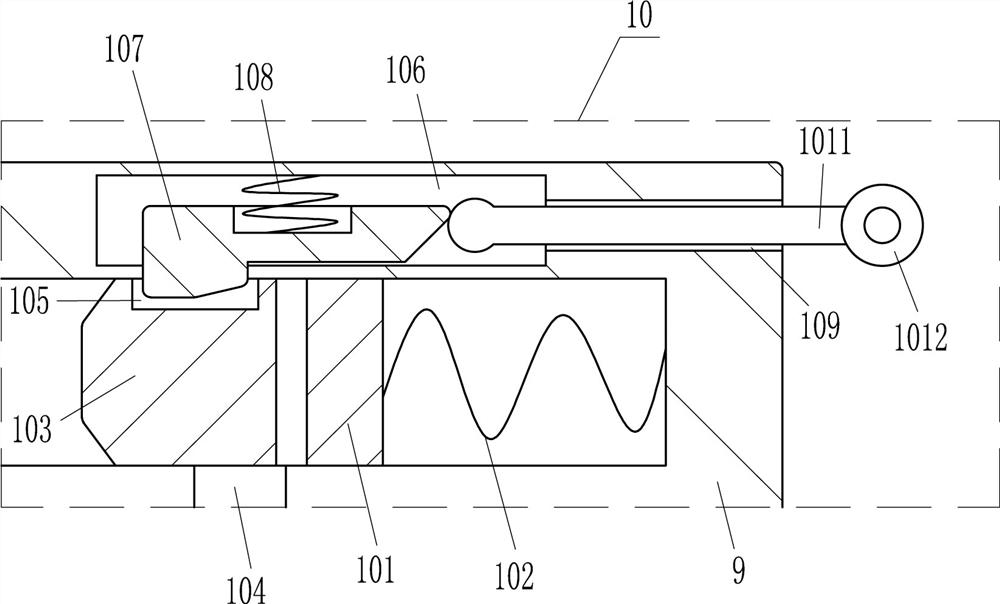

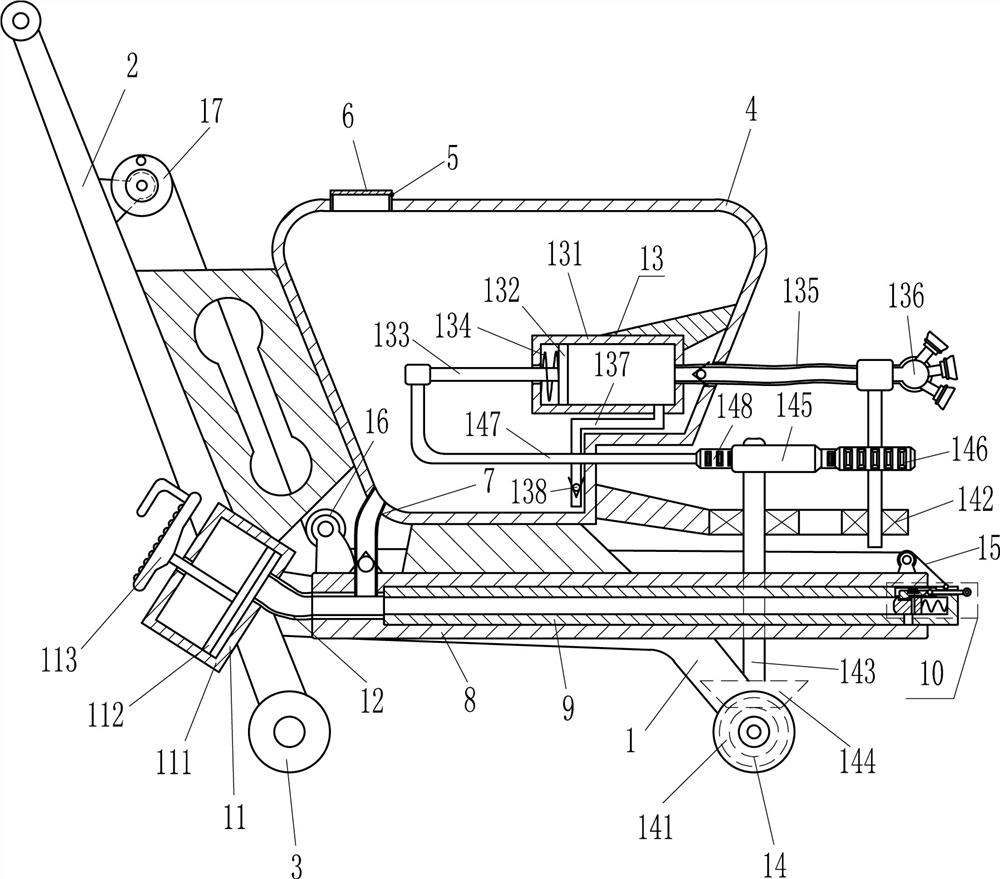

[0019] as attached figure 1 to attach figure 2 As shown, a corner disinfection equipment for sanitation management includes a mounting plate 1, a first push rod 2, wheels 3, a liquid storage tank 4, a liquid inlet pipe 5, a cover plate 6, a liquid outlet pipe 7, and a hollow sleeve 8 , hollow pipe 9, sprinkler 10, power unit 11, first hose 12, liquid sprinkler 13 and transmission device 14, first push rod 2 is installed on the left side of the top of the mounting plate 1, and wheels 3 are installed on the bottom of the mounting plate 1 , the top of the mounting plate 1 is equipped with a liquid storage tank 4, the top of the liquid storage tank 4 is provided with a liquid inlet pipe 5 with a cover plate 6, and the left side of the bottom of the liquid storage tank 4 is connected with a liquid outlet pipe 7 with a one-way valve, A hollow sleeve 8 is installed in the middle of the mounting plate 1, and a hollow tube 9 is slidingly provided in the hollow sleeve 8. The tail end ...

Embodiment 2

[0026] as attached figure 1 As shown, the power unit 11 includes a first cylinder 111, a first piston 112 and a pedal 113, the first cylinder 111 is installed on the lower part of the first push rod 2, and the first push rod 2 is connected to the first push rod 2 by bolts. A cylinder body 111 is connected, the first cylinder body 111 is slidingly provided with a first piston 112, the first piston 112 is connected with a foot pedal 113 for stepping on, and the first piston 112 is connected to the foot pedal 113 by bolts. Connected, the pedal 113 is located outside the first cylinder 111 .

[0027] Working principle: When disinfecting corners, the operator first steps on the pedal 113 upwards, thereby driving the first piston 112 to slide upwards in the first cylinder 111, and pumps the disinfectant in the liquid storage tank 4 into the first soft cylinder. tube 12, and then step down on the pedal 113 to press the gas in the first cylinder 111 into the hollow sleeve 8, push the...

Embodiment 3

[0031] as attached figure 1 Shown, also comprise backguy 15, fixed pulley 16 and reel 17, hollow tube 9 top right sides are connected with backguy 15, hollow casing 8 top left and right sides all are equipped with fixed pulley 16, hollow casing 8 passes bolt The connection mode is connected with the fixed pulley 16, the first push rod 2 is equipped with a reel 17 with a handle, and the backguy 15 is connected with the reel 17 around two fixed pulleys 16.

[0032] Working principle: when the hollow tube 9 is pushed to move to the right, the winding wheel 17 will automatically release the wire. After the corner is sterilized, the operator turns the winding wheel 17 to collect the pull wire 15, and pulls the hollow tube 9 to move to the left to reset. In this way, the hollow tube 9 can be reset more conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com