A method for forming a magnesium alloy hollow four-layer structure

A layer structure, magnesium alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easy oxidation of the surface, difficult to eliminate, high activity of magnesium alloys, etc., to improve forming efficiency, reduce production costs, increase Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

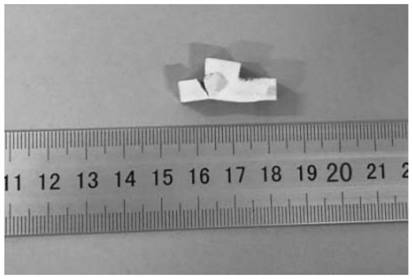

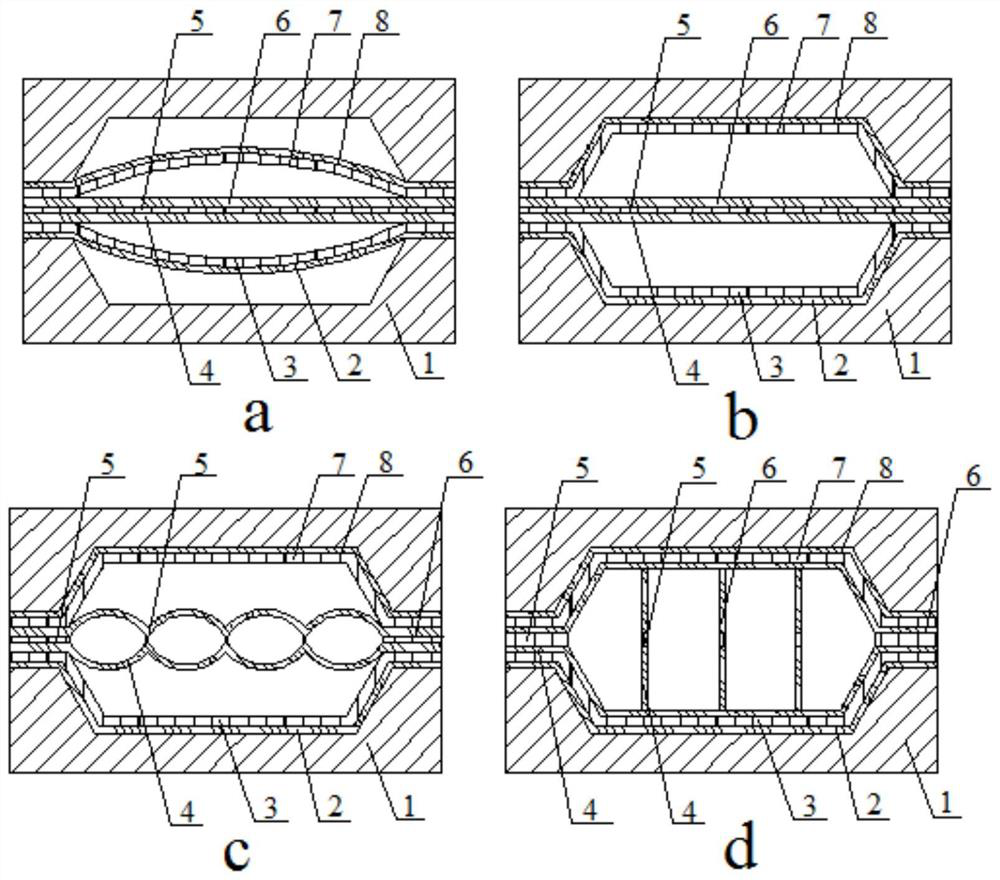

[0032] Specific implementation mode 1: This implementation mode is an integrated forming method of low-temperature forming / high-temperature reaction-diffusion connection of a magnesium alloy hollow four-layer structure, which is completed according to the following steps:

[0033] 1. Pretreatment:

[0034] Remove the oil and scale on the surface of the magnesium plate, and then clean the copper foil to obtain a pretreated magnesium plate and a pretreated copper foil;

[0035] 2. Preparation of core board:

[0036] First, spray 3mm~5mm peelable adhesive on one surface of the pretreated magnesium board, and then fix the peeling board on the surface of the magnesium board sprayed with peelable adhesive. The surface of the magnesium board sprayed with peelable adhesive is not covered with the peeling board. The area is the solder resist area, then remove the peelable adhesive at the solder resist area, remove the peeling plate, and then spray the release agent solution on the sol...

specific Embodiment approach 2

[0054] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, a peelable adhesive of 3 mm to 5 mm is first sprayed on one surface of the pretreated magnesium plate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0055] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, silicon carbide sandpaper 180#, silicon carbide sandpaper 400#, silicon carbide sandpaper 800#, metallographic sandpaper 400# and Grind the surface of the magnesium plate with metallographic sandpaper 800# until the surface of the magnesium plate is bright, and then ultrasonically clean the magnesium plate in acetone for 5 minutes to 10 minutes to remove the oil and scale on the surface of the magnesium plate to obtain a pretreated magnesium plate. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com