Welding method for effectively inhibiting weld toe defects of medium-thickness plate annular weld joint

A technology of circular welds and welding methods, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as safety hazards, structural fractures, welding defects, etc., and achieve high-strength welding, convenient operation, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

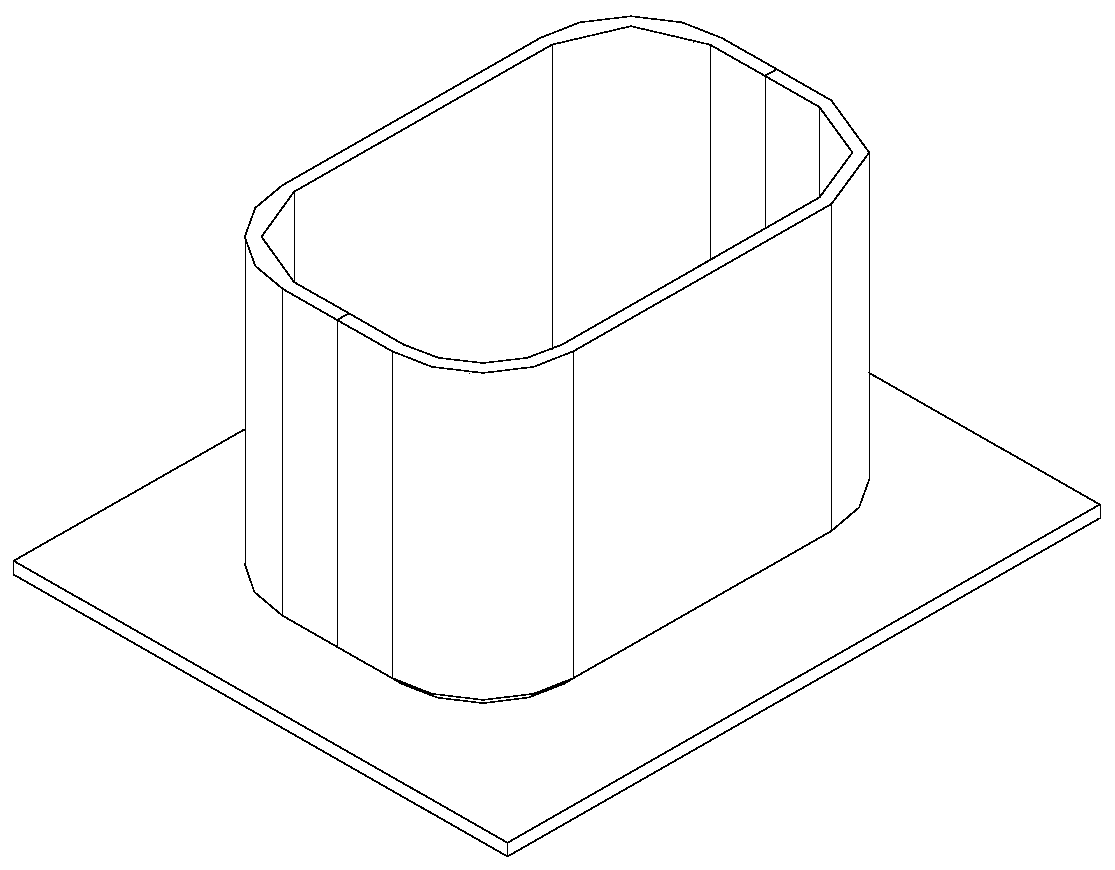

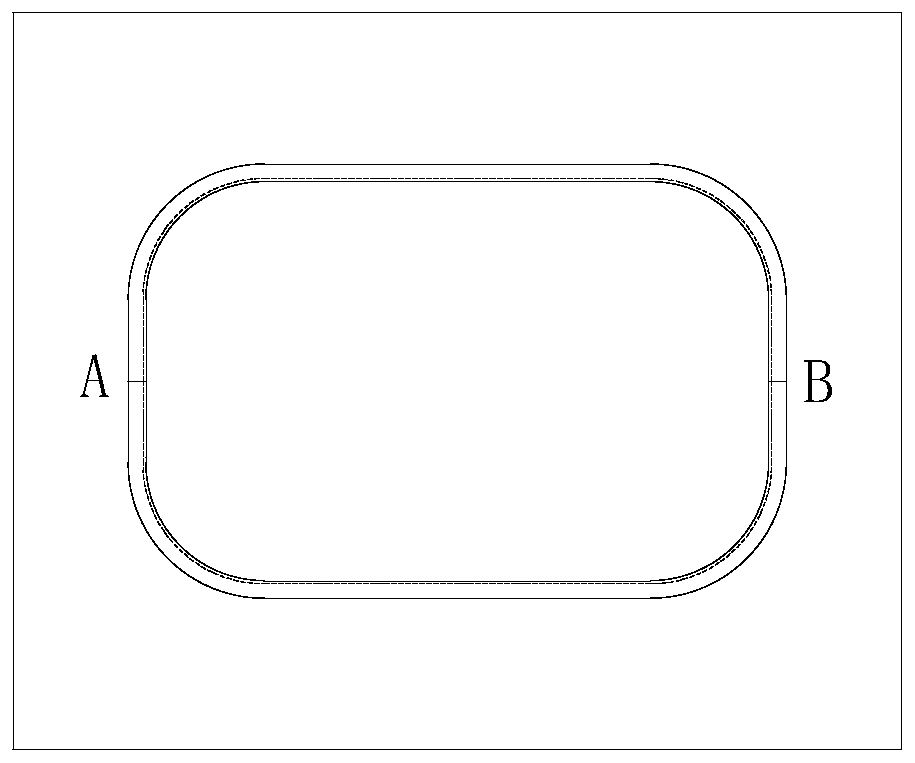

[0024] Such as figure 1 , figure 2 As shown, the welding process method for effectively suppressing the weld toe defect of the circular weld seam of the medium and thick plate described in the embodiment of the present invention includes the following steps:

[0025] a) Bevelling: The beveling angle of the rectangular tube is 45°, and the blunt edge is 2mm;

[0026] b) Fixing: rigidly fix the bottom plate before welding;

[0027] c) Preheating: The arc stays for a while after the arc is struck by the welding power source, and the groove is preheated, and the wire feeding starts when the surface of the molten pool is slightly depressed;

[0028] d) Tack welding: the workpiece butt gap is ≤ 2mm, and the tack welding is performed on both end faces, and the tack welding height is ≤ 4mm;

[0029] e) Bottom welding: Bottom welding is performed on the groove, using single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com