Non-continuous inlaid combination type animal grease squeezing device

An animal fat, combined technology, used in presses, manufacturing tools, etc., can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

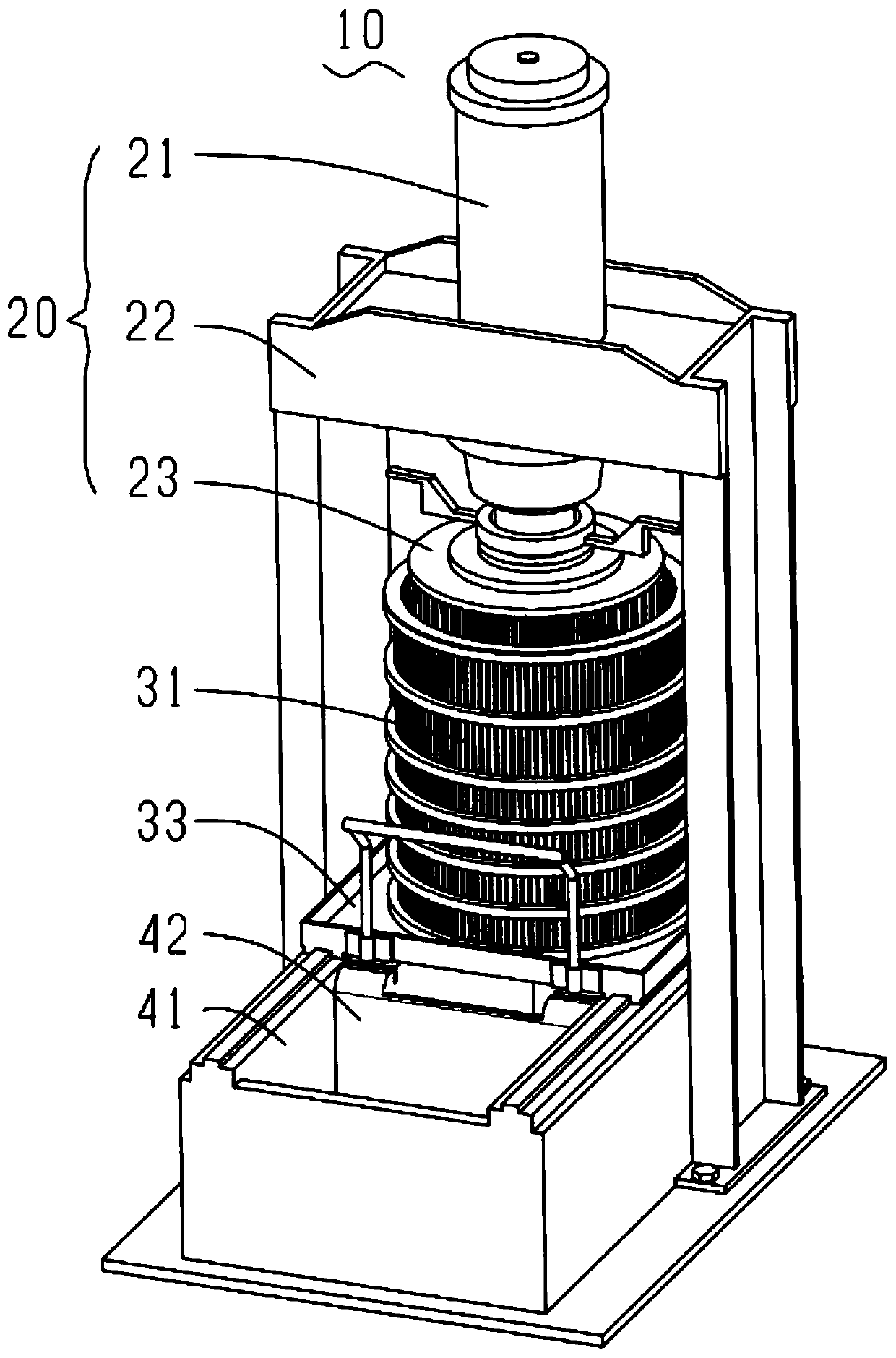

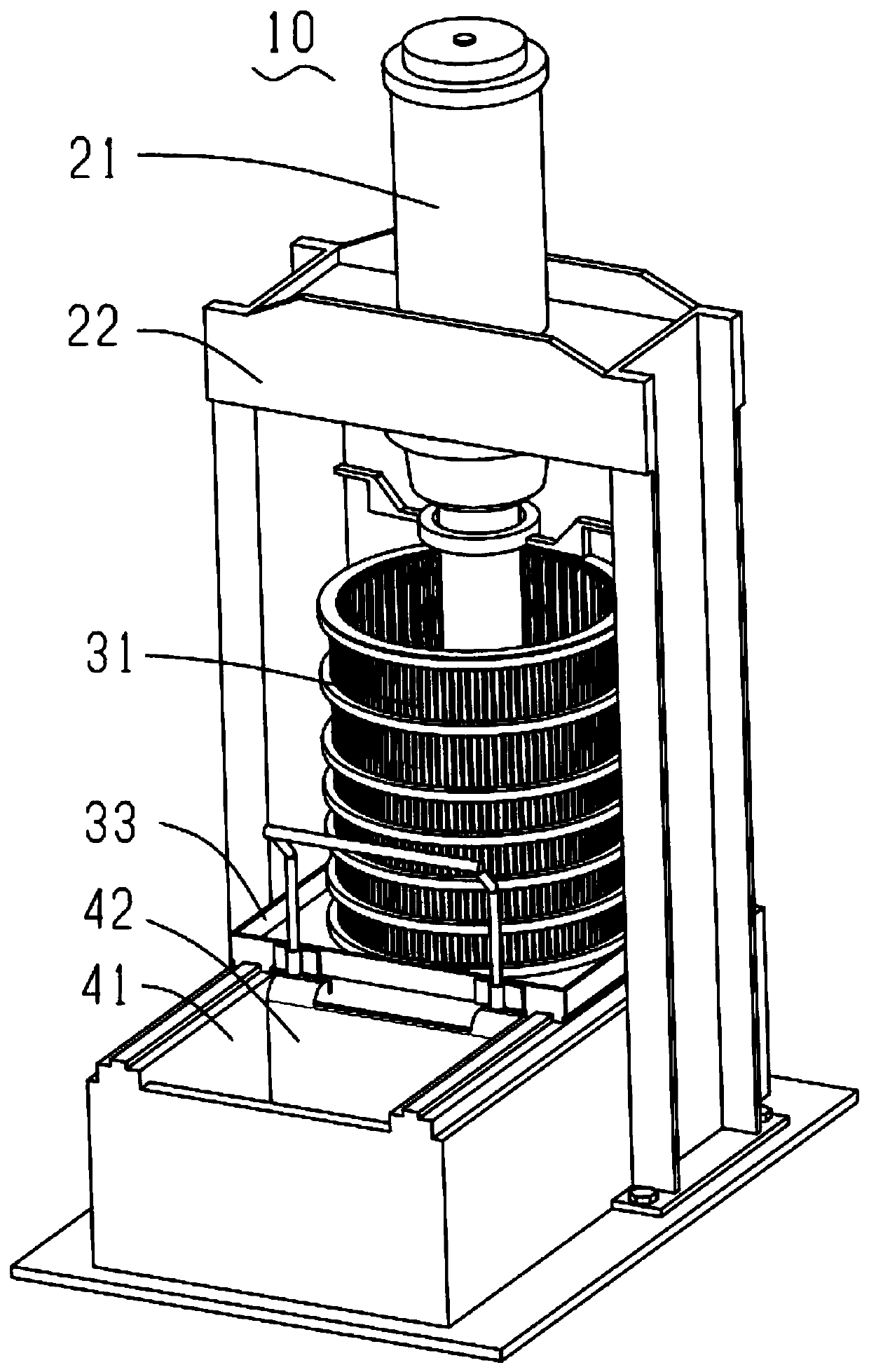

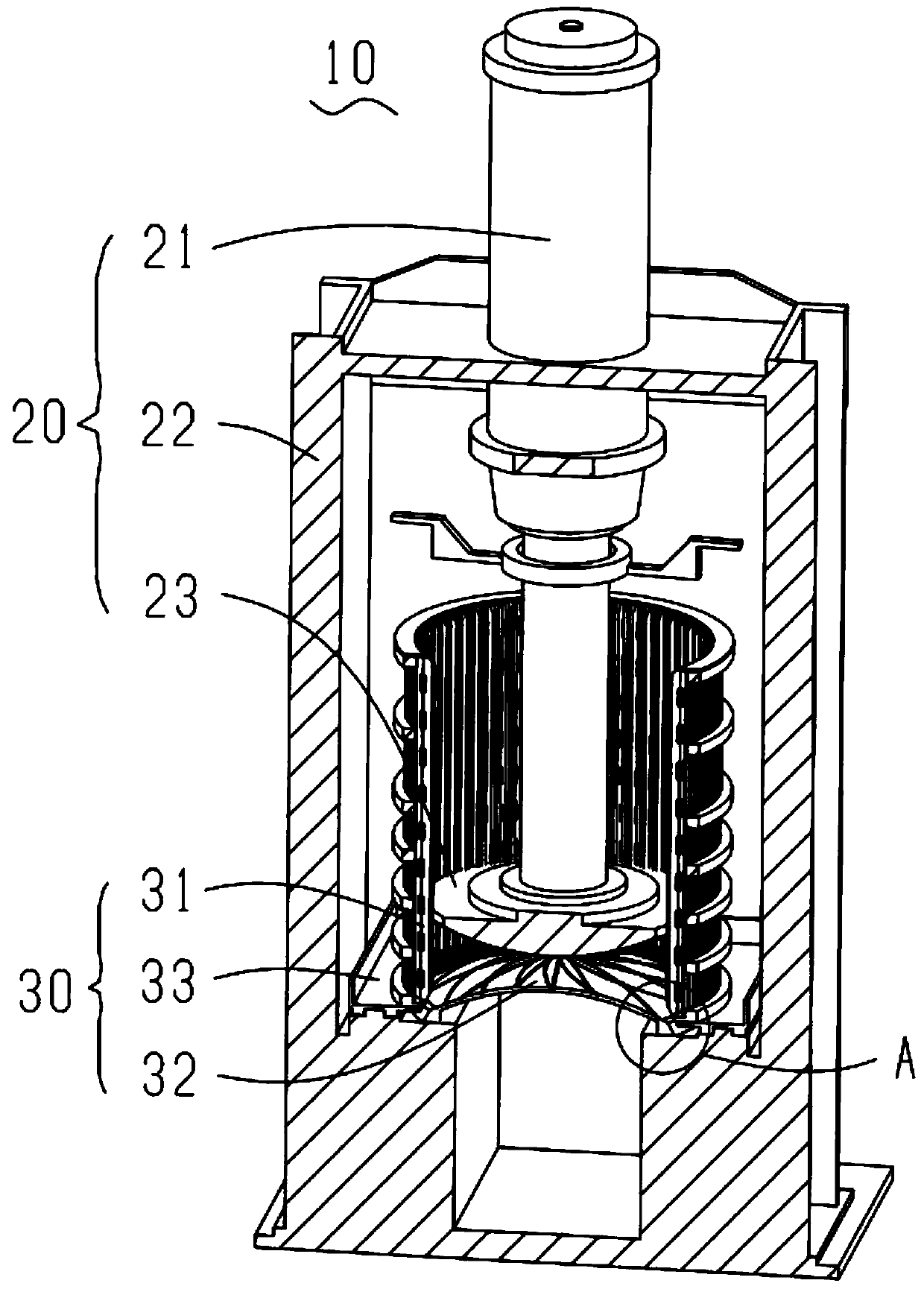

[0030] Please see Figure 1 to Figure 6 , the embodiment of the present invention provides a non-continuous mosaic combined animal fat pressing device 10, which is used to squeeze the slag in the animal oil dregs produced after the smelting of animal fats, so as to squeeze out the residual oil in the dregs, including an oil filtering device 30 , squeezing device 20, oil residue collection device 40, oil filtering device 30 is positioned at the top of oil residue collection box 41, oil residue collection device 40 comprises oil residue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com