Combined splicing type refrigerator car floor sectional material assembly

A splicing technology for refrigerated vehicles, which is applied to superstructure sub-assemblies, vehicle parts, superstructures, etc. It can solve problems such as unsightly floors, no consideration of connection problems, and lack of anti-seepage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

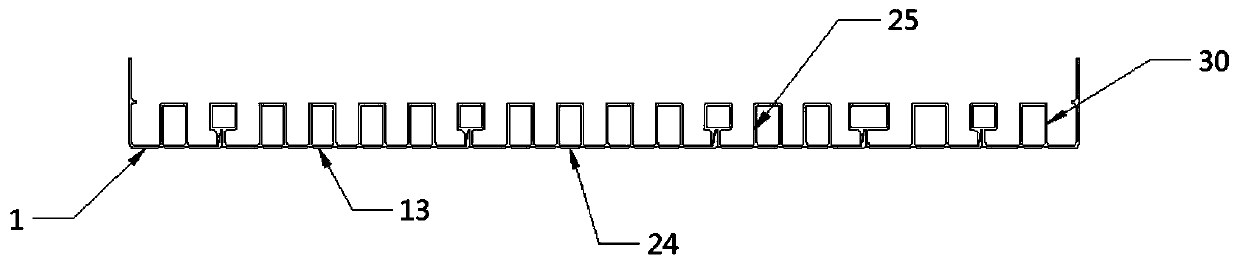

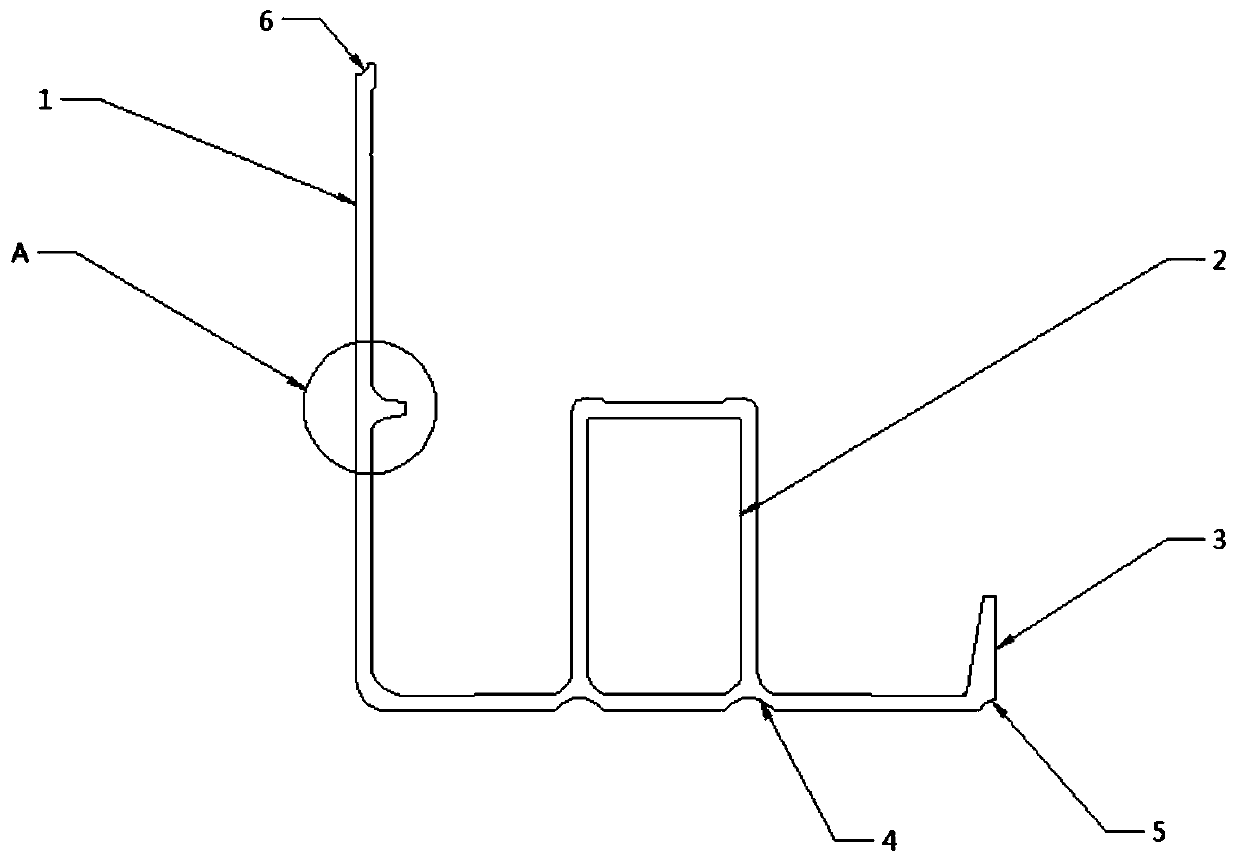

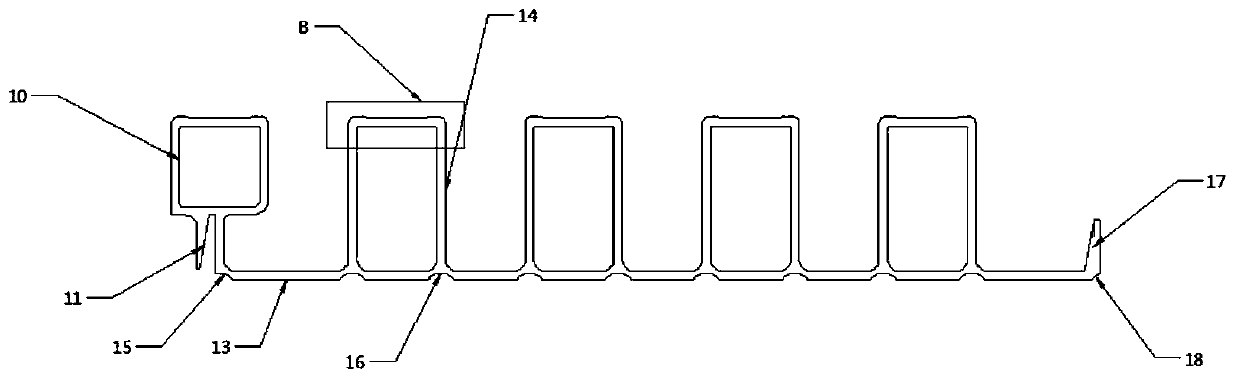

[0028] Such as Figure 1-Figure 9As shown, a combined splicing refrigerated vehicle floor profile assembly provided in this embodiment includes a first floor profile 1, a second floor profile 13, a third floor profile 24, a fourth floor profile 25, and a fifth floor profile 30 Connecting the profile 7 with the front bottom, the side of the first floor profile 1 is clamped with the side of the second floor profile 13, and the second floor profile 13 is away from the side of the clamping part of the first floor profile 1 and the second floor profile 13 The side part is clamped with the side part of the third floor profile 24, and the side part of the third floor prof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com